I am extremely excited to announce that our subscription service now offers the Naturally Aspirated header fabrication skills course, this now joins our Staple skills of fabrication, MIG Welding and TIG welding skills courses and starts the new year off with more motorsport fabrication knowledge for you to learn.

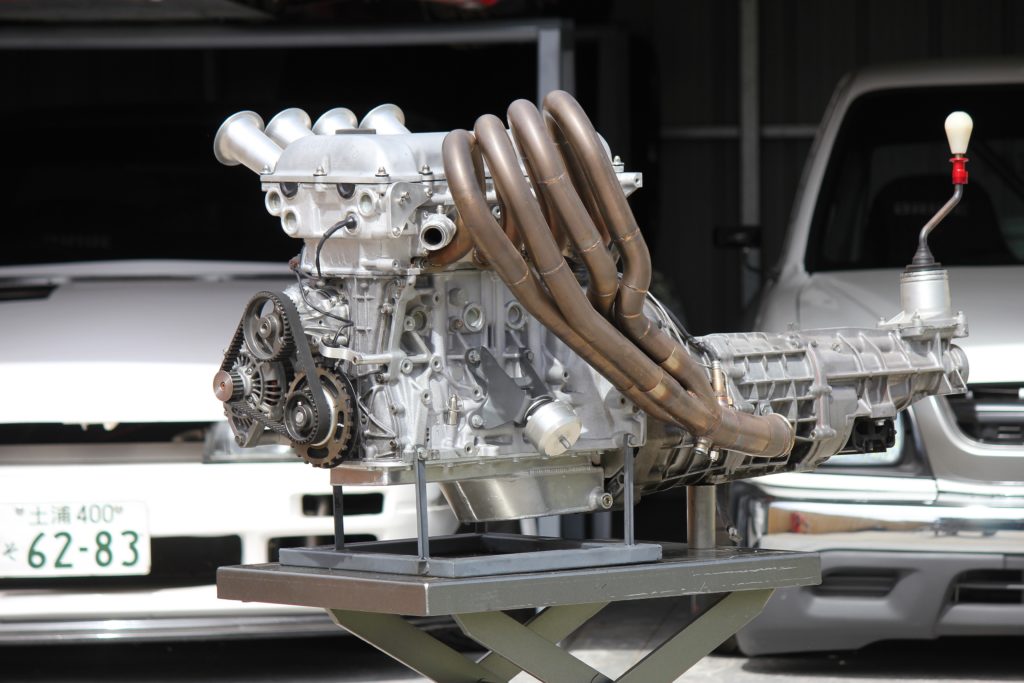

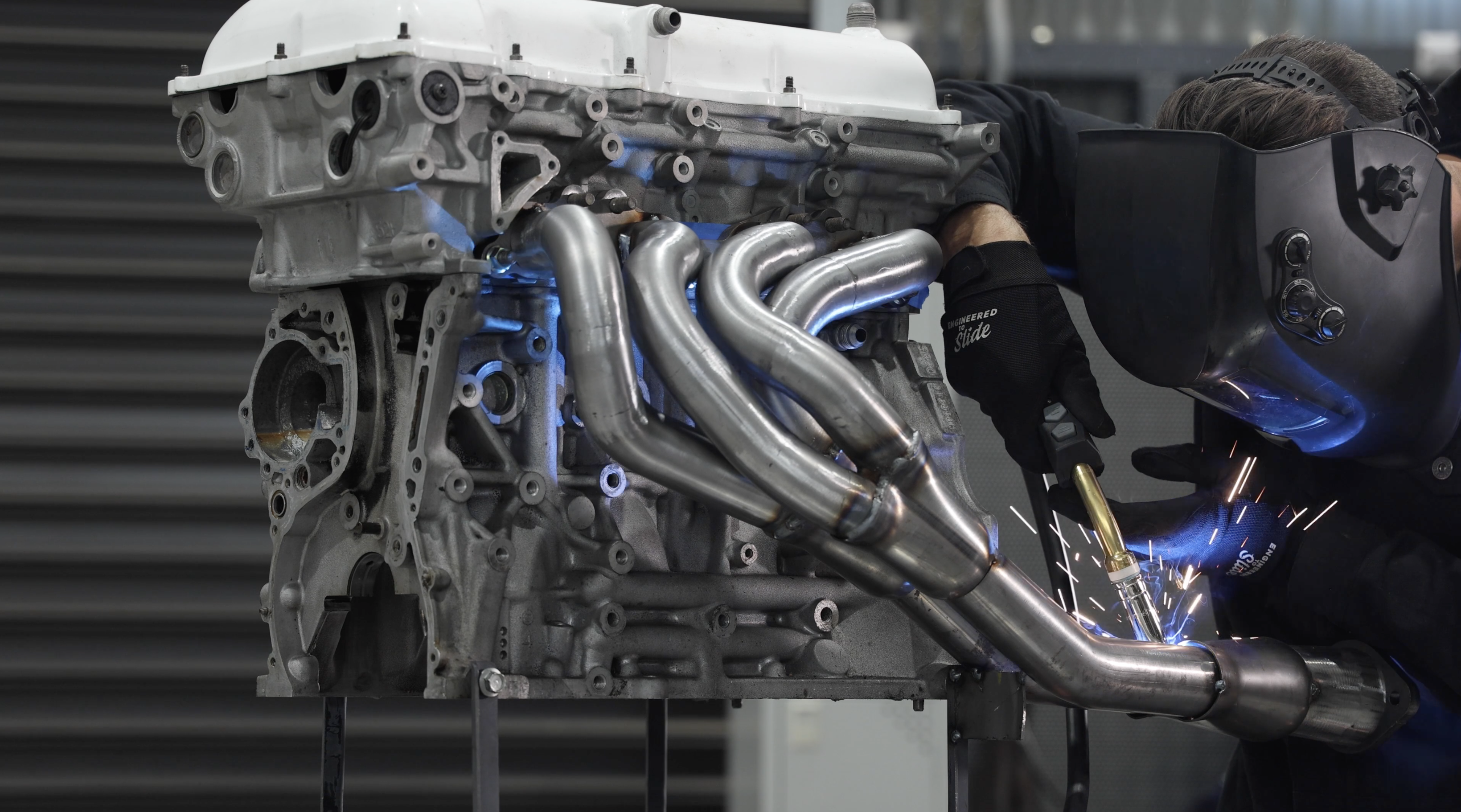

If you’re familiar with Engineered To Slide then you would have seen my exploits with the naturally aspirated PS13 SR20 project, building this motor and designing the header for it was a huge learning curve a it took a couple of goes to get right. From this project I put together the Naturally Aspirated Header Fabrication skills course and this is aimed to take all the guess work out of your header project.

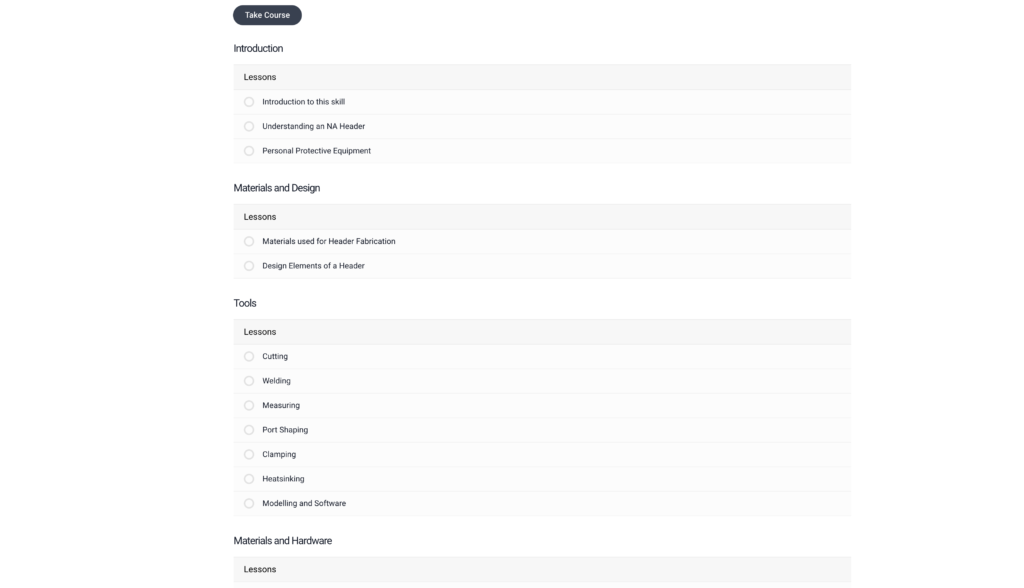

With 27 individual process videos we start looking at our design and material options suited to our intended outcomes.

This course isn’t completely directed at those fabricating their own header either, its extremely useful for figuring out your intended header to match your intended peak torque and RPM. What I mean by this is the mathematics that we cover in the course will allow you to design your own header and then shop around for something that gets close to your intended goals.

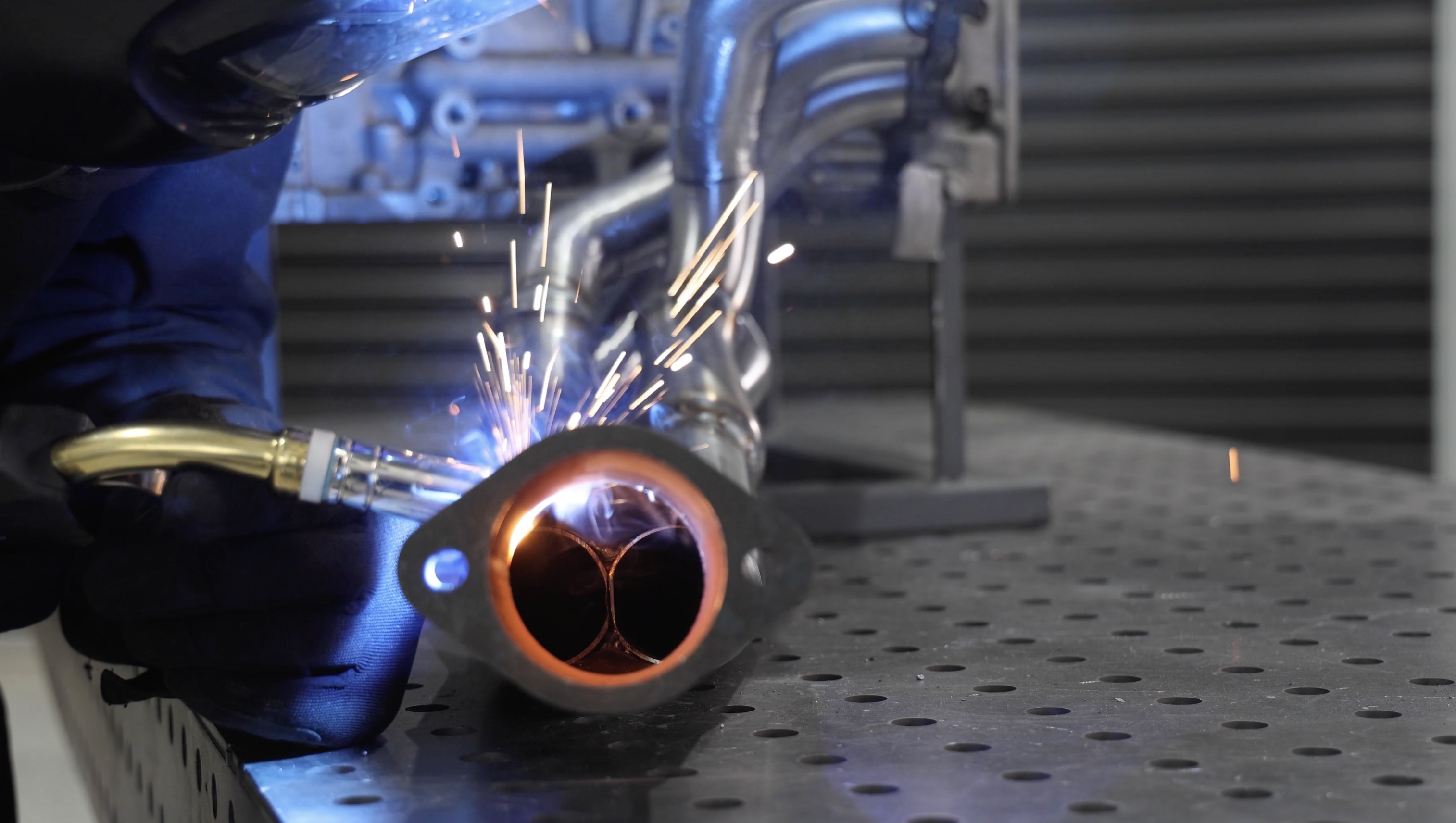

If your intended header is not available off the shelf (and lets be honest its not easy to find variations to those often outdated designs) then your only option is to build one. Above is a sample of the course and this details the heat sinking that is required to maintain a flat header flange that will assist in the seal between the cylinder head and the exhaust header.

I cover the design, tools, materials, fabrication techniques and all the considerations along the way to make sure nothing is left to question.

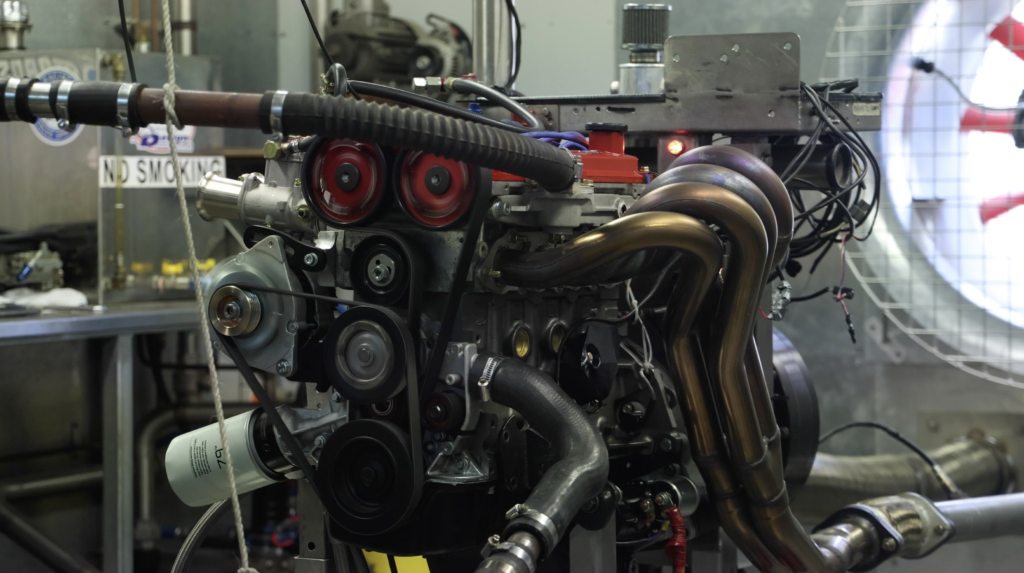

So when it comes time to proving your exhaust on the dyno, street or track you will know that your getting the optimal performance from your naturally aspirated engine, and as we all know this is extremely important when dealing with NA performance engines.

Once you have completed the course you can view the projects section to see all of this knowledge and fabrication in practice.

The first is a header I built for my good friend Casey from Shirtstuckedin and you can see this project come to life in the project video.

The next project was all about reducing costs and time with a mild steel MIG welded SR20 header and this also focuses on a reduced amount of tools to show what is possible on a tight budget and timeframe.

This Skills Course along with all our other Courses and Projects are included in our low monthly or yearly subscription plans and the value increases with time, theres nothing like it and theres no better way to tap into decades of industry experience to produce your very own performance parts. .

Thanks for reading, Nigel.