I hit a snag, i wanted my exhaust dead straight so that i could undo the mount in the cabin and slide it straight out, i couldnt do this with the X in the diffuser bracing, so i cut it out and then added some strength with tube.

The exhaust is dead straight for over 3 meters.

I bought two J legged 90 degree bends and made the collector, its a pretty simple process and one ill have to do on the 180SX again on Sunday.

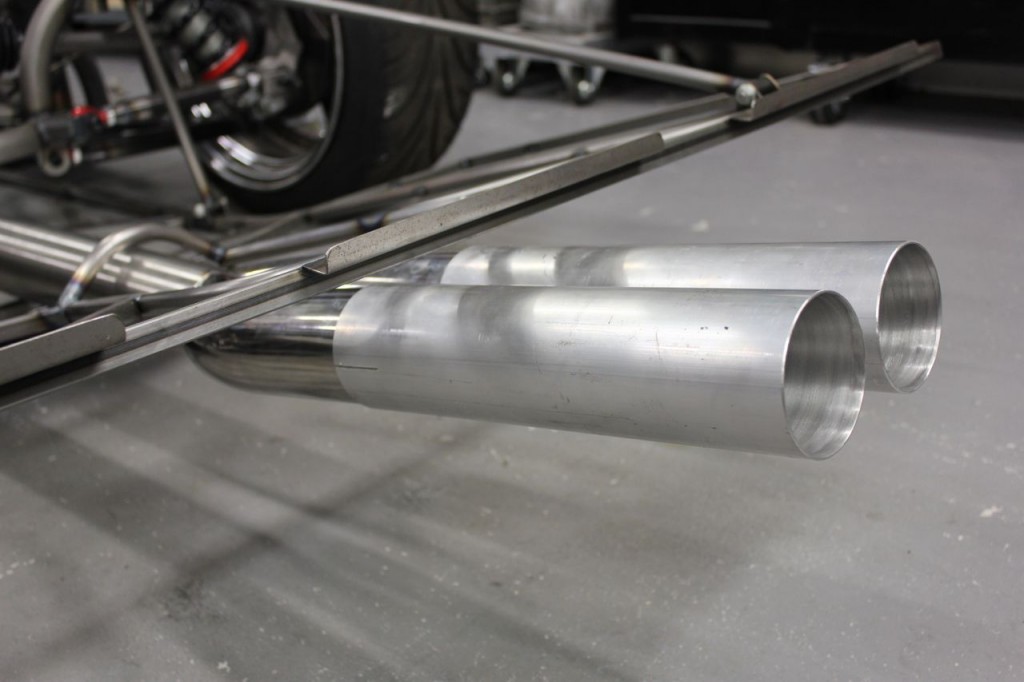

The alloy tips are 80mm x 1.6mm wall and are the perfect size to press over the stainless, im not 100% sure what lengths i want them so this will be handy.

Jason

Nigel, what size master cylinder will you be using for your hydro handbrake? Great work as usual.

Diditte S

Hi Nigel… when you tig weld the stainless exhaust tubes do you also pump argon gas inside them?