If you have been following this build from the beginning then you would have seen the evolution of the cooling layout.

It started as simply running an S15 style radiator, then as time went on it started becoming a trouble area, i decided to run the radiator in front of the intercooler, that idea lasted a week and then i decided to run it in the rear, after thinking about all the unnecessary extra plumbing needed i started to rethink that idea.

In the end i thought stuff it, no off the shelf radiator or intercooler was going to satisfy my taste for fitment and quality like a custom made one would.

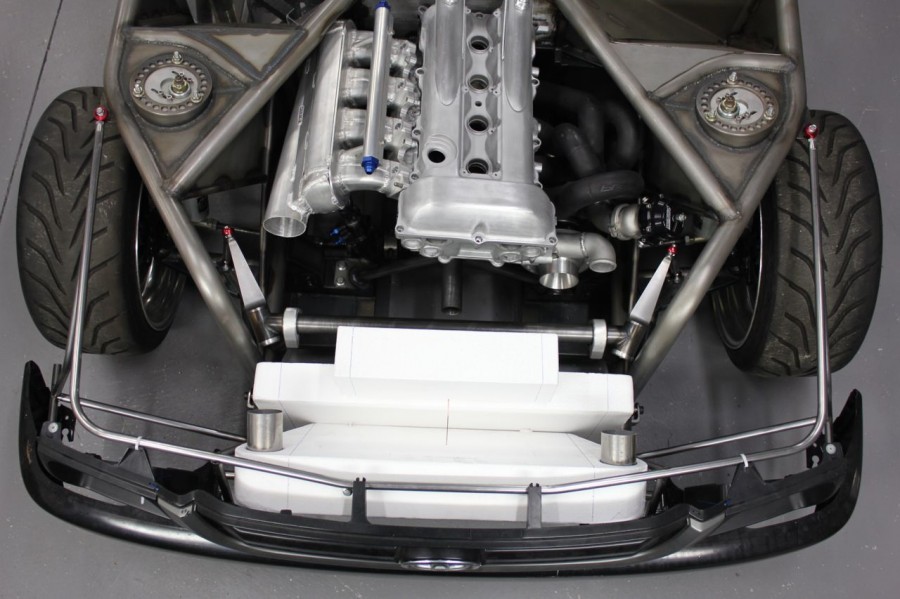

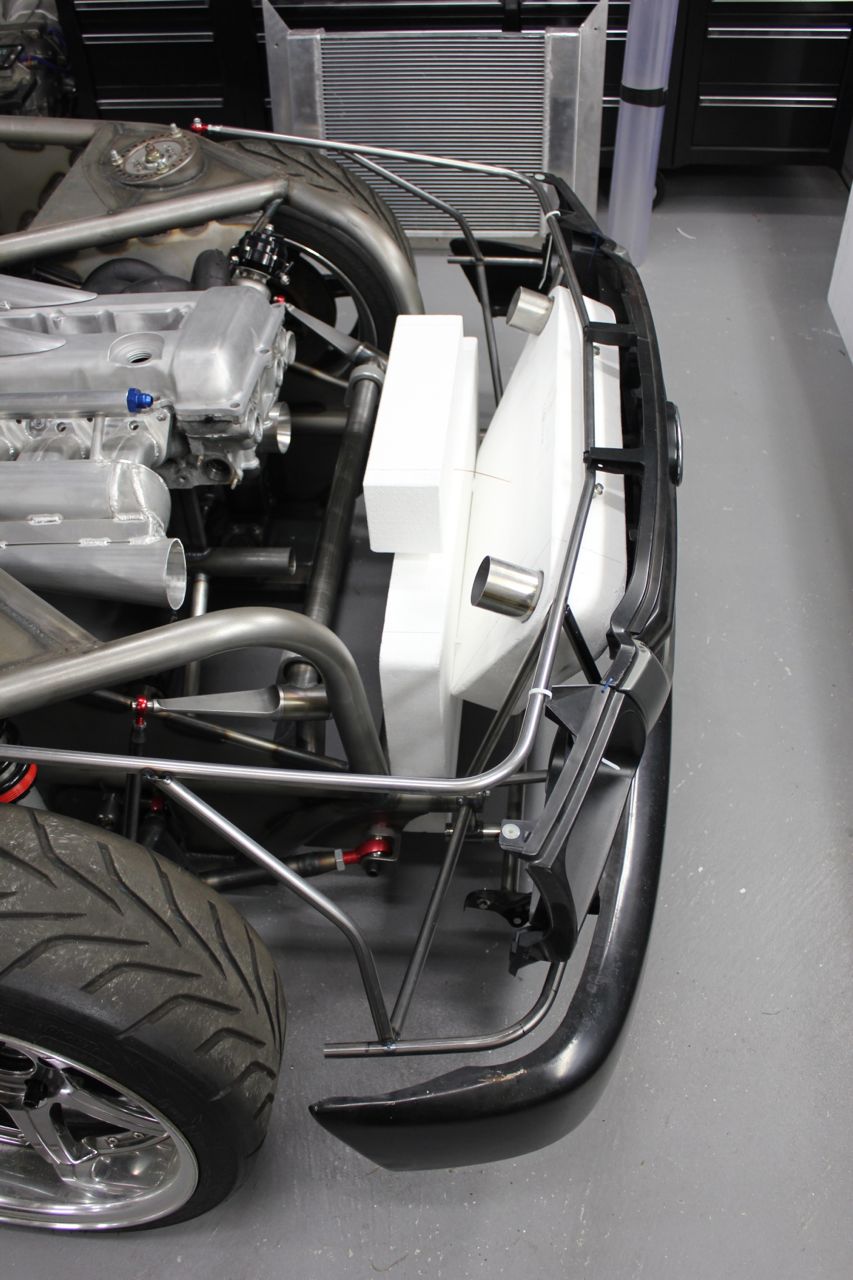

After the chassis was rolling, the front tube structure was made and the panels fitted i grabbed some polystyrene and started cutting it out to emulate my intercooler and radiator.

Once i was happy with the layout i started to draw the design, after the physical size was worked out i could start thinking about plumbing.

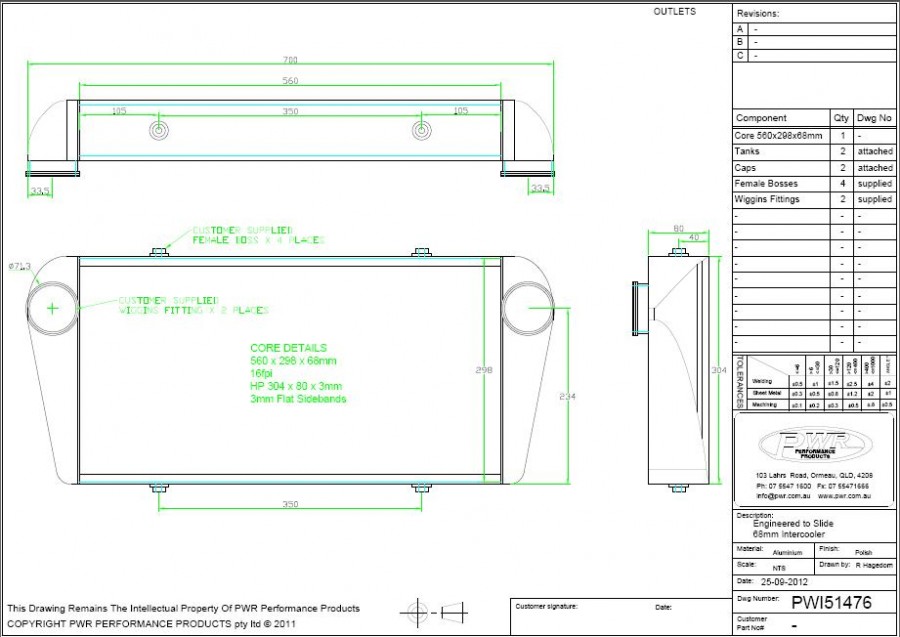

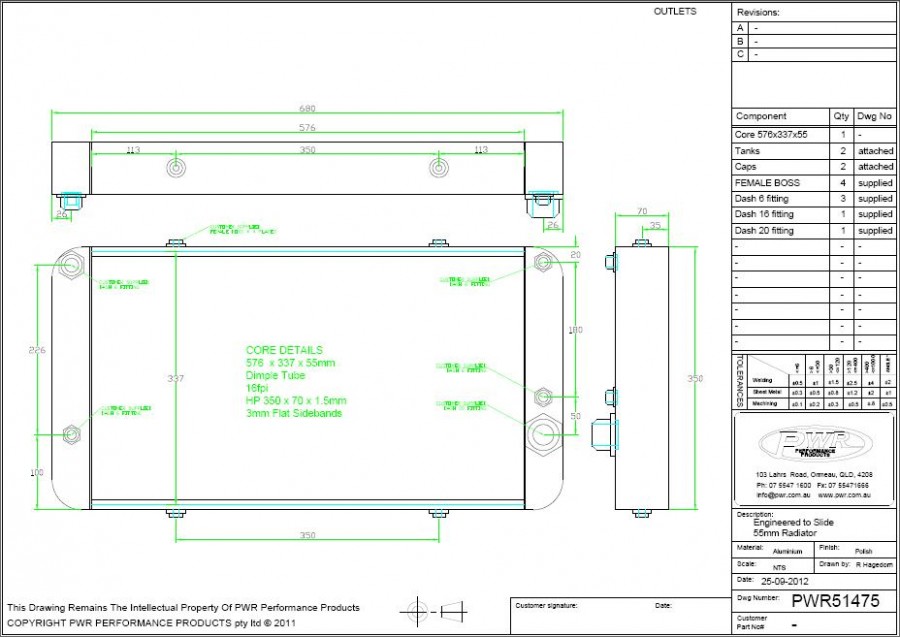

I ordered Wiggins style clamps for the radiator and weld on -20 and -16 fittings for the radiator and then sent all my fittings and drawings off to QLDs PWR.

If you have not heard of PWR then you must be living under a rock, PWR are the world leaders in affordable quality radiators and intercooler’s and service nearly every style of Motorsport in the world. If its good enough for F1 cars then its good enough for me.

Funnily enough the Paul Wheel Racing family behind the company grew up in the same small Victorian town as i did and that enclosed trailer i bought my ute to WTAC in was built by Paul.

So now the drawings are all finalized my intercooler and radiator will be going through the steps you see below to produce the finishing touches to the cooling system in my build, i am so happy i went this route because having a quality intercooler and radiator are critical in keeping this build reliable for my entire lifetime.

JDMized

Cool shit Nigel, cool shit!

I’m mounting my radiator on the rear kickers that come down from the main loop (much like a Baja Truck). The plumbing shouldn’t be too hard, and with some custom CNC machined brackets, the aluminum pipes will store plenty of fluid and keep the engine’s temp down.

I’m sure you’re gonna go with a very similar setup.

Keep it up 🙂

Matt

Awesome stuff, Nigel! Every update is just a new page full of inspiration. Love that swaybar setup, and love the new radiator/IC setup. Can’t wait to see what happens next!!

Parker

Nice! You guys down under are lucky to call PWR “affordable”. For a dual-pass unit for my S2000 would cost me nearly $1000 USD!

luke

how much was the radiator to get made ?