Spending so much time shaping the rear panels has given me some time to think about whats next to do on the chassis side of things, I decided to start making the floor sections and sheeting in the wheel arches, firewall and rear cabin wall. Read on for the latest.

Spending so much time shaping the rear panels has given me some time to think about whats next to do on the chassis side of things, I decided to start making the floor sections and sheeting in the wheel arches, firewall and rear cabin wall. Read on for the latest.

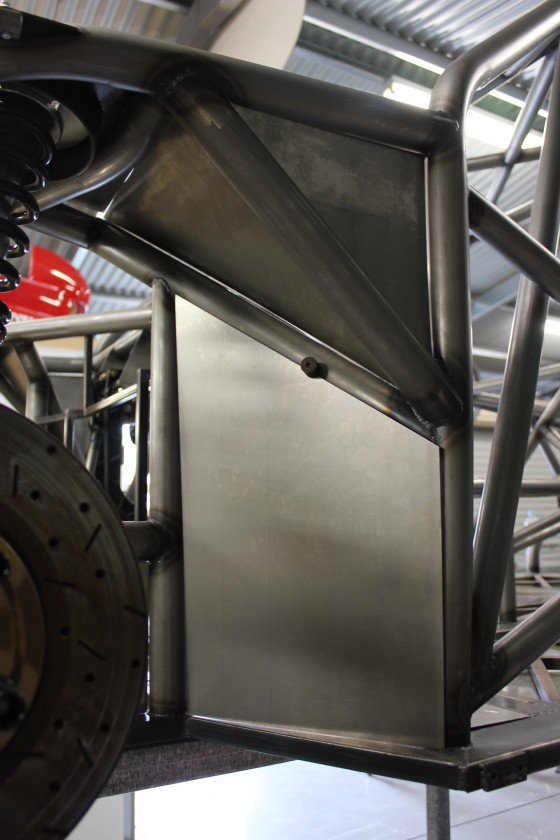

The few spare hours i had on the weekend were spent making platic templates so i could get the tin work done right the first time. A sheet of clear plastic and a few hours makes the actuall cutting of the steel fairly straight forward.

The few spare hours i had on the weekend were spent making platic templates so i could get the tin work done right the first time. A sheet of clear plastic and a few hours makes the actuall cutting of the steel fairly straight forward.

The plastic templates also come in handy if there needs to be any repairs made in the future. This steel is .9mm sheet and will eventually be stitch TIGed in.

The plastic templates also come in handy if there needs to be any repairs made in the future. This steel is .9mm sheet and will eventually be stitch TIGed in.

I dont want to weld it all in untill my brakelines and motor plumbing are done, its much easier to drill holes in sheet on the bench than in the car.

I dont want to weld it all in untill my brakelines and motor plumbing are done, its much easier to drill holes in sheet on the bench than in the car.

Not to mention that i also want to buff everything to a nice shine before all the welding is done, im still toying with the idea of a clear coated chassis if i can do everything neat enough.

Not to mention that i also want to buff everything to a nice shine before all the welding is done, im still toying with the idea of a clear coated chassis if i can do everything neat enough.

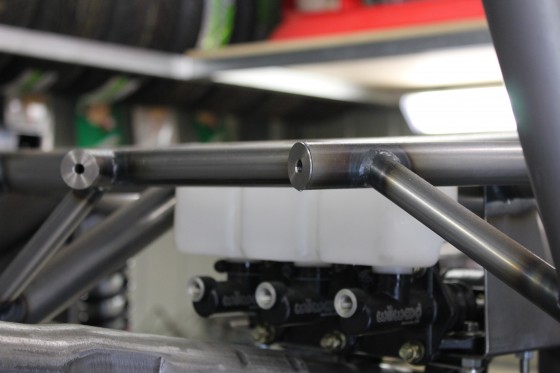

Before World Time Attack last year i quickly mounted a steering column to shift the car around, now that the utes up on the chassis bench i can rework this and design something a little neater.

Before World Time Attack last year i quickly mounted a steering column to shift the car around, now that the utes up on the chassis bench i can rework this and design something a little neater.

I cut off the old unit and added some tapped M8x1.25mm bungs that will hold a steering bracket in association with a Racepak data display and logger. Its a good feeling to be progressing again, the only problem is each step from now on requires more $$ than time…. I need to buy a heap of stuff to keep the momentum going and get this driving!

I cut off the old unit and added some tapped M8x1.25mm bungs that will hold a steering bracket in association with a Racepak data display and logger. Its a good feeling to be progressing again, the only problem is each step from now on requires more $$ than time…. I need to buy a heap of stuff to keep the momentum going and get this driving!

p dub

loving this project man! i check for updates every day haha

just a quick question and don’t hate me for asking this but where you planning on running the exhaust?

Nigel

I havnt figured that out yet, its a minor issue compared to the entire task ahead haha

Aaron

Clear coat is a geat idea

Anthony

just curious, what are the little red and black round things on the inside of the front wheel arches? and also where do you get .9mm sheet metal from as i want to use some inside my car to fill up the holes where my interior was 🙂 and of course great work as usual!

Nigel

They would be magnets, used to hold the panel inplace to weld it in, any steel shop should be able to get you sheetmetal.