The highlights have been non stop this year, sure small business has its highs and lows but when a highlight like this comes along I celebrate! Being on this list is a really exciting opportunity for myself. My 2014 honeymoon had Born Free as a destination and it blew my mind and changed the course of my life for good. To be on this list with the finest builders of our generation is something that should be celebrated. Just below me at number 18 is Jasin Phares, for those avid readers you may remember Jasin as being a pivotal person in my 2017 USA Adventure on my chrome Panhead. Jasin and the other builders on this list are world class, to be named amongst them is a humbling experience and one that I wont be taking for granted.

So what is Born Free? Born Free Show is a motorcycle show set in Southern California and is best explained by the founders themselves “The Born-Free Show is a back to basics motorcycle event built on the shared passion of people building and riding their motorcycles. This is a place where motorcycles of all makes and models take the spotlight. The laid back atmosphere and beautiful landscape of the Oak Canyon Ranch creates a one of a kind family friendly event that is a refreshing change from the controlled chaos of the typical modern motorcycle event. Born-Free features a special invited builder area where thirty of the worlds finest motorcycle craftsmen will debut bikes they’ve been building just for Born-Free. These guys are small shop owners, and garage builders pushing themselves to create new future classics.”

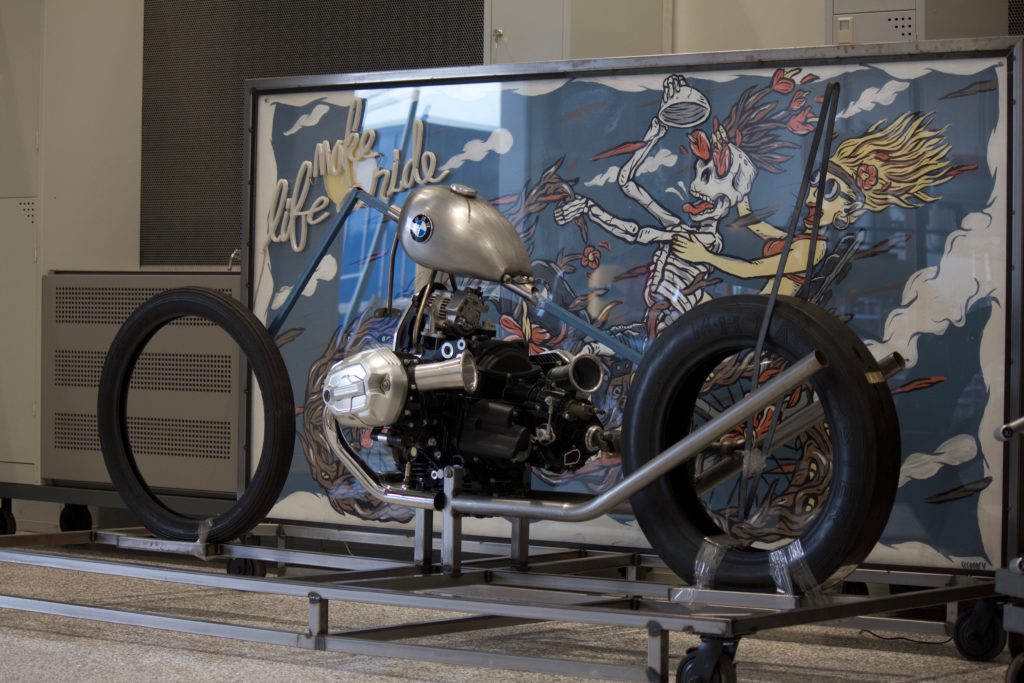

My contribution to next years event will be one air freighted BMW Chopper, it’s a project that I kicked off at the beginning of the year and you can keep up to date with all that is happening with the Heritage range of BMWs by clicking here. I took it to a few events to give people the idea of the concept and now things have escalated 10x and my plans are slightly changing.

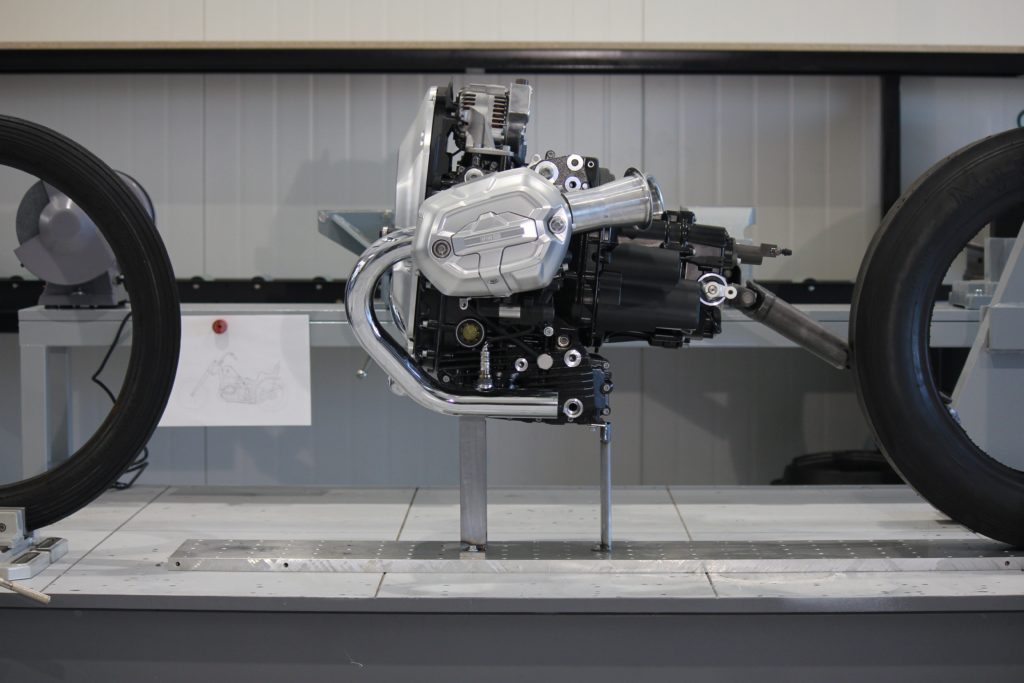

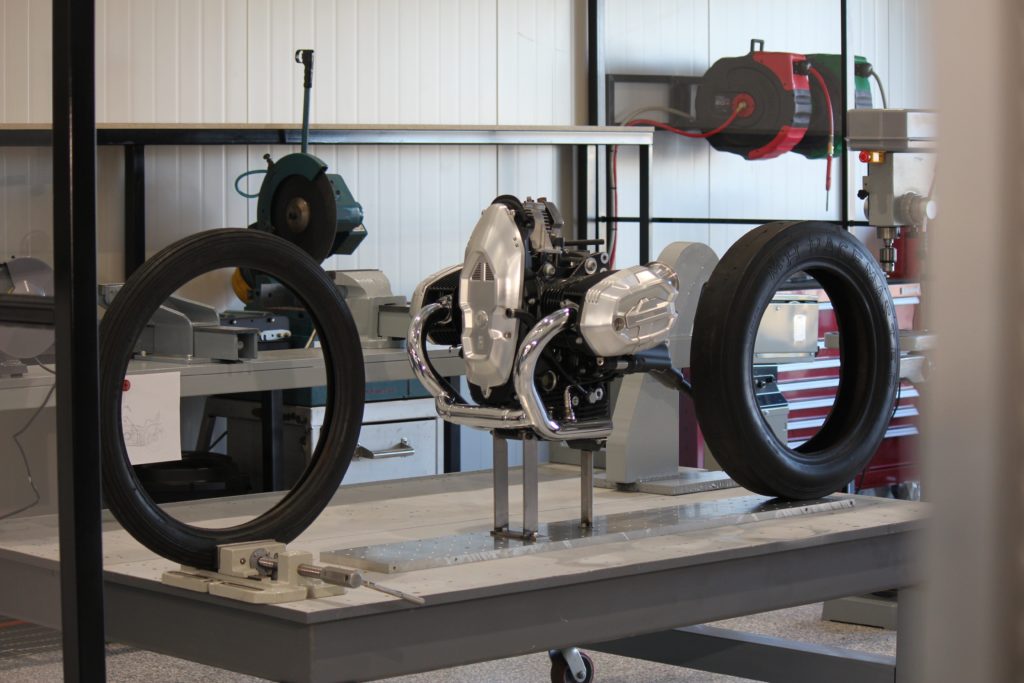

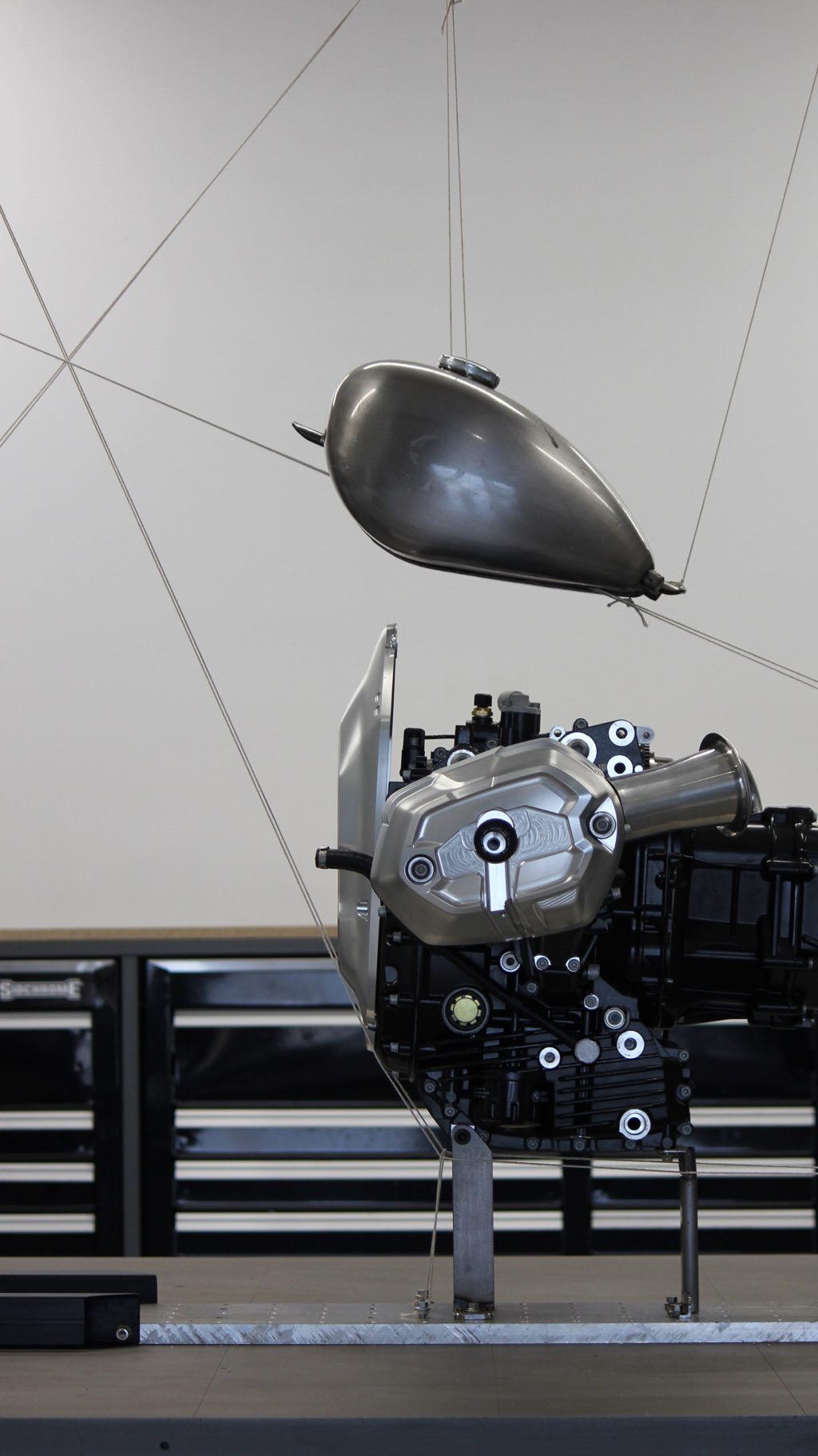

Step one was to pull the motor out of the display frame and prepare it for the frame jig. (Just look at those Option 719 covers)

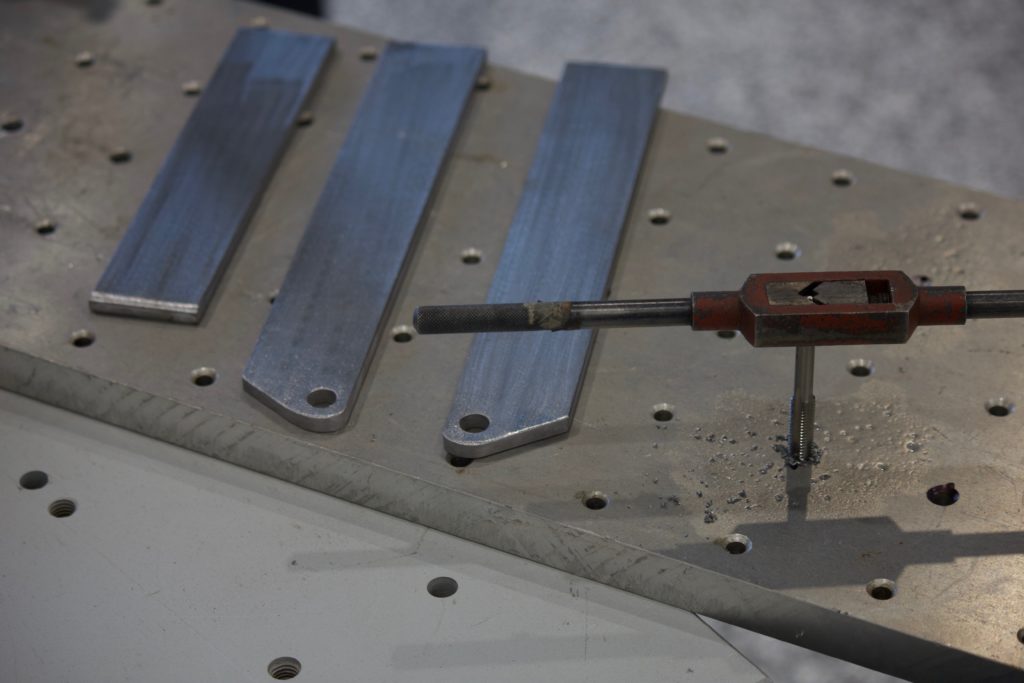

I have had this 20mm plate kicking lying around since the last build, its drilled with 6.5mm holes every 50mm and allows me to tap M8 threads to make engine mounts on.

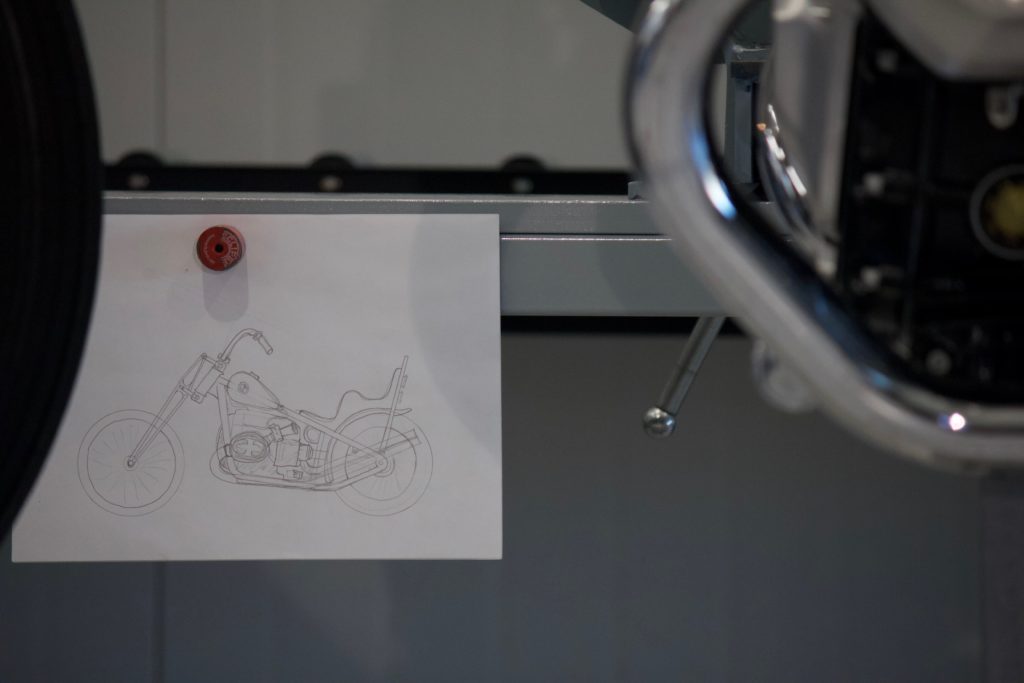

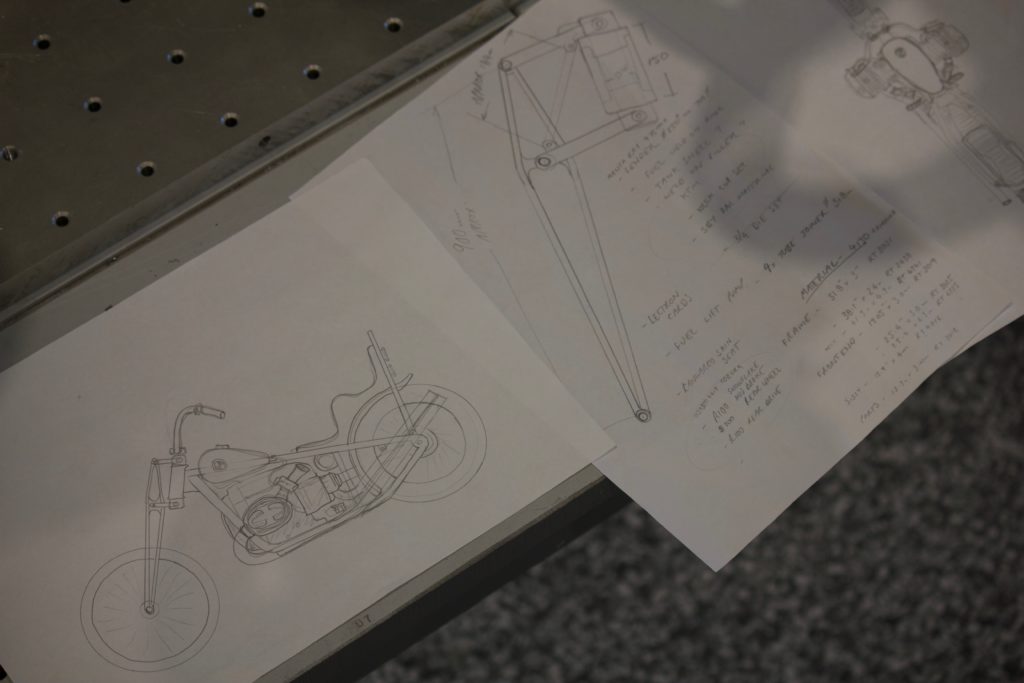

With the bike (or part of it) up on the bench I can start to plan the build.

There is a lot to plan.

But where do I start? What do I plan off? Where do I even begin?

I found a rear rim from a 1960’s drum brake BMW for sale so I picked that up and fitted the M&H Racemaster slick from Coker Tyre.

I then found a wrecker in Melbourne that had a rear drive unit (some call it a diff, some call it a bevel drive) in good condition and this will allow me to mock everything up.

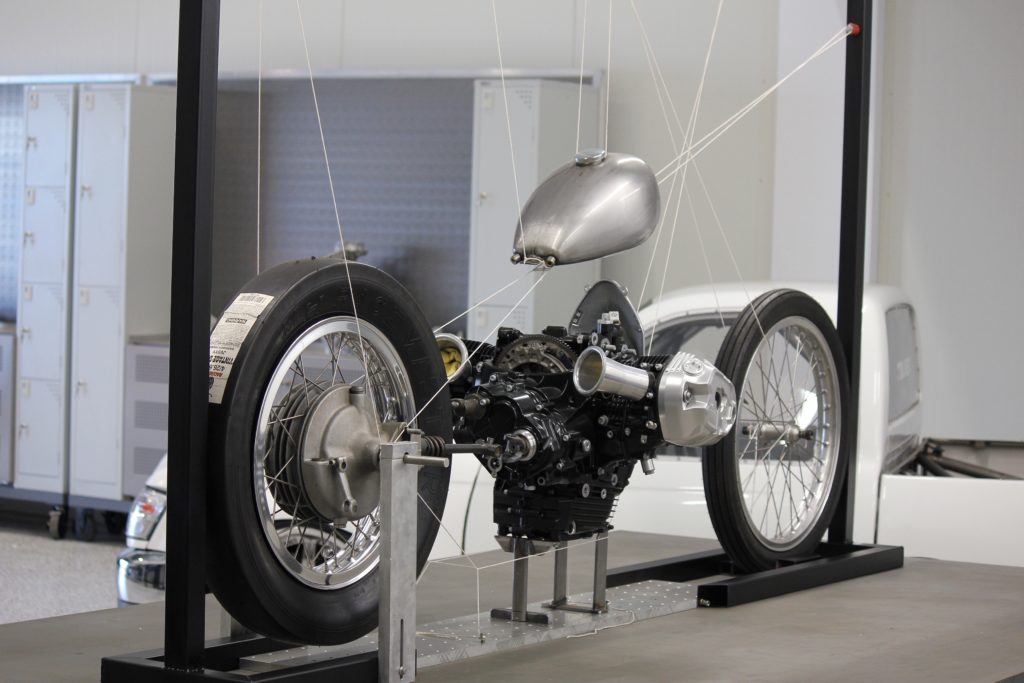

Once back home I could start to get a feel for the overall bike.

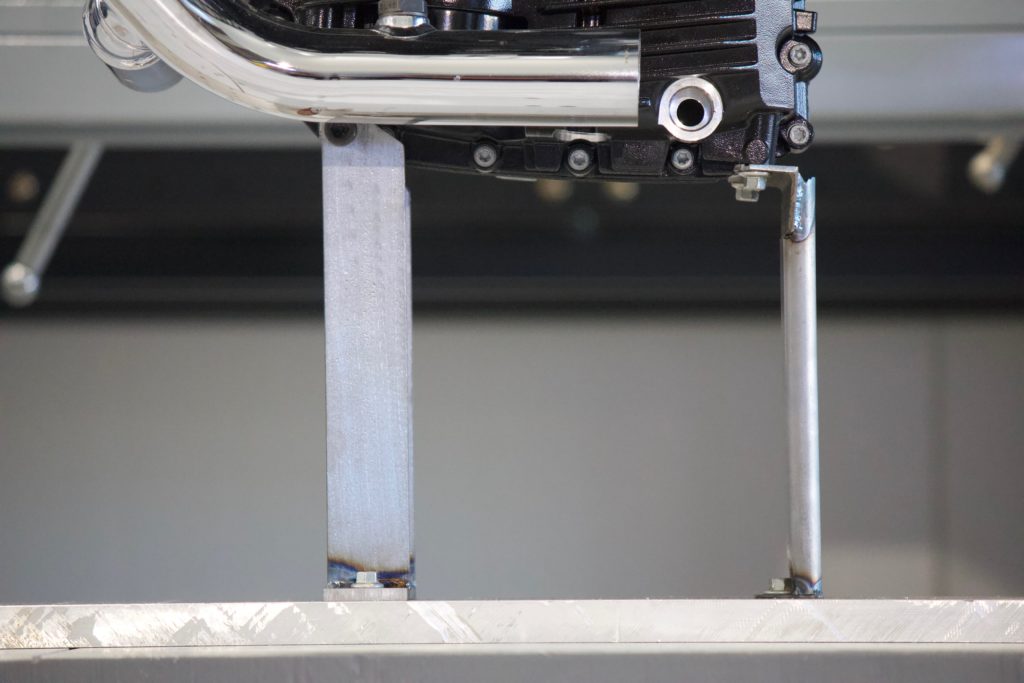

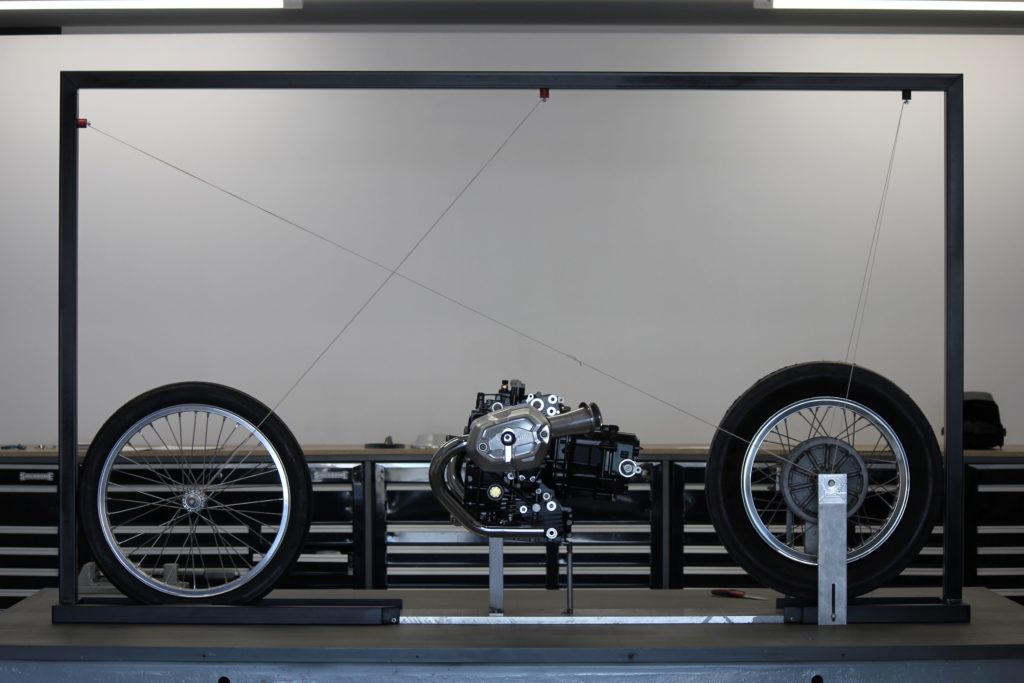

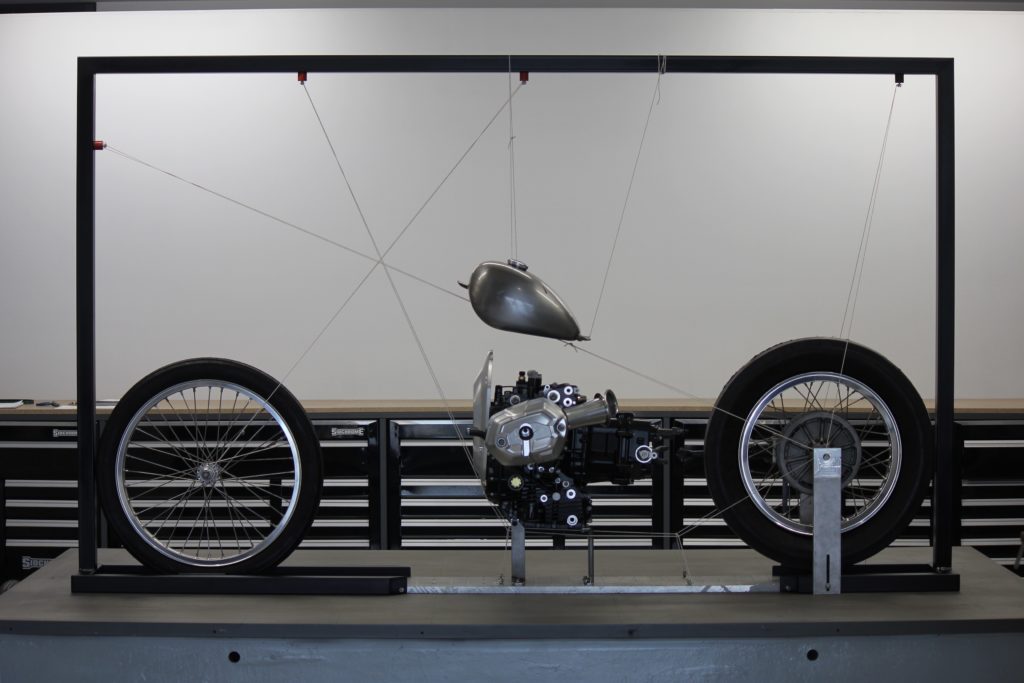

But I just couldn’t feel for the lines, it just didn’t look right. I had a length of 50mm tube left over and decided to make a frame to allow me to hang and position components where they need to be.

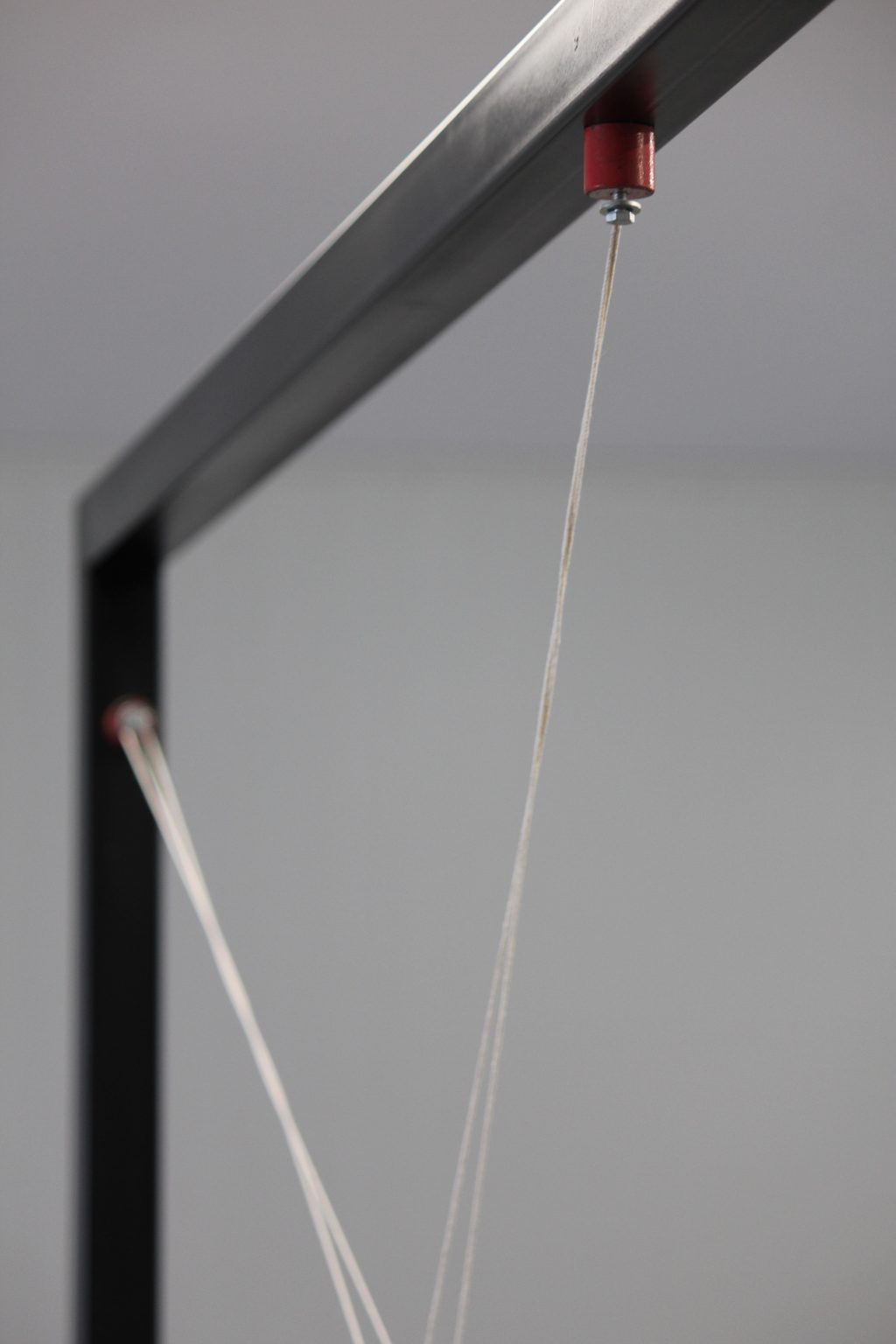

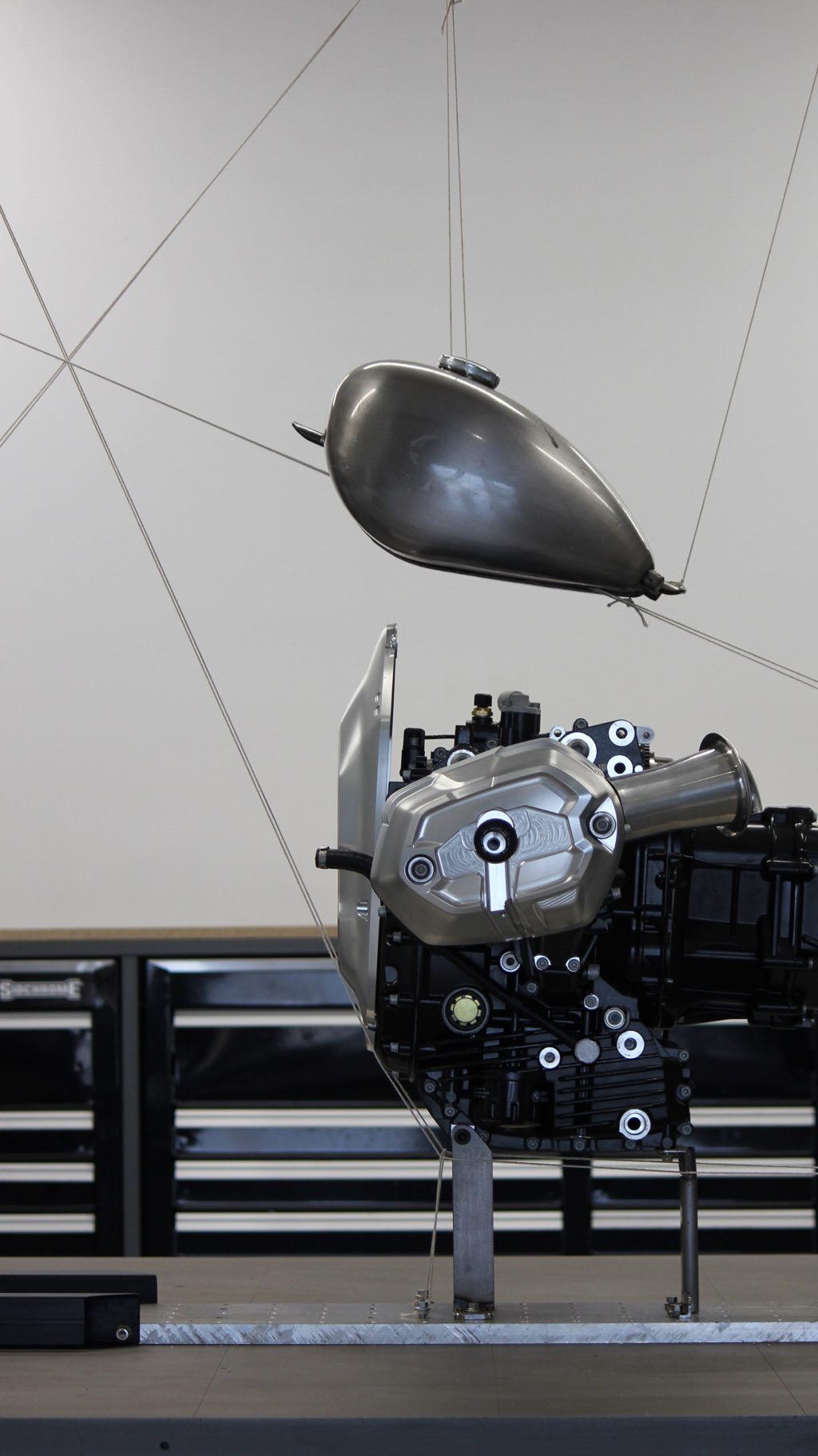

Now I could use magnets and string to get some lines into the build. It also allowed me to easily manipulate and reposition items before final dimensions were locked down.

I knew something didn’t look right, I dropped the motor 50mm and moved it back 50mm, this gave the frame lines a much more traditional shape. The BMW motor is very short and this gets worse when the alternator is removed. I am removing the alternator and replacing this with a traditional magneto. I had a good conversation with the guys from Morris Magneto in the USA and they can develop a magneto with a 180 degree cam that drives off the crankshaft. This will allow the bike to have a wireless ignition system that will be rotatable for fine ignition tuning. Big thanks to the guys from Morris Magneto for their assistance with this.

These wheels wont be the ones I am running, the wheels I am running will be the original 1960’s Snowflake design CNC machined out of billet 6061 Aluminium, this rear tyre has a large diameter so I am matching it with a 22″ front tyre that has a 28″ outside diameter, or course a motorcycle never came out with a 22″ tyre but I have found one and I will make the rim to suit.

Actually Matt will do that, Matt has been working part time with me between study and it makes super complex jobs like these a lot easier.

By spending a day making this frame I can now understand exactly what I am doing and what the lines will look like.

So whats planned for the build? Think about this….. Carbon fibre tank and fender, polished 4130 Chromoly frame and girder front end with raw TIG welds, CNC machined wheels, Titanium exhaust with printed tips, Magneto ignition, duel carburettors, all finished in a tinted clear to show the metals and composites but give the bike a very uniform appearance. Cannot wait, I will keep you up to date with regular posts.

Interested in learning fabrication and want a little guidance from me? Check out my range of courses so you can make your dreams a reality.