The last post depicted this cars time on the dyno, with the car back home I still had a lot of work to complete and thats what I want to run you through in this post.

I cant express how relaxed I felt returning home with a functioning car, a year ago I contemplated cutting this shell up and taking it to the scrap metal plant, to see it here as a driving and functioning car with everything I had ever dreamt of (minus a 6 speed sequential gearbox, haha) was as soothing as a week in a yoga retreat.

I have always been interested in the philosiphy of how humans operate and more specifically operate in a monor that allows them to complete huge projects that span many years. There has to be a balance of anxiety, enough to keep you going, but not so much that you take the easy route and give up, there has to be those shining moments where you appreciate what you have done and that in turn motivates you to keep going.

I have come a long way with this car and I have learnt a LOT, in 2006 I pulled apart my 180SX drift car and took it to the tip, it was really beat up and I needed a fresh start, I pulled the drive train out and bought an AE86, a week later I found this car, sold the AE86 for a profit and picked this up. From CA18-SR20-LS1 (I actually gave up on that before I finished it thank god) back to SR20 and then it got stripped to build the Hilux in 2010.

A little bit of that AE86 inspiration rolled over into this car, the idea of a high revving 220ps NA track car sparked a journey that I am glad I persisted with.

There’s an old saying “less is more” its something I have been chasing for a long time, with maturity brings understanding and with that this car progressed with less parts but more integration and mechanical understanding.

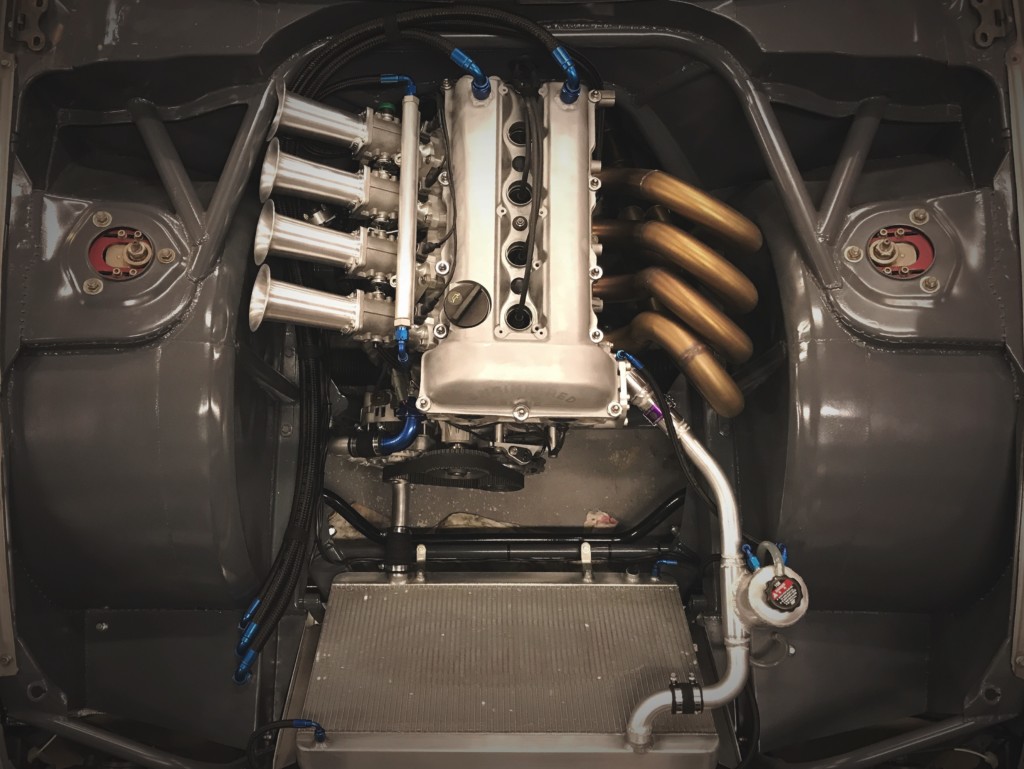

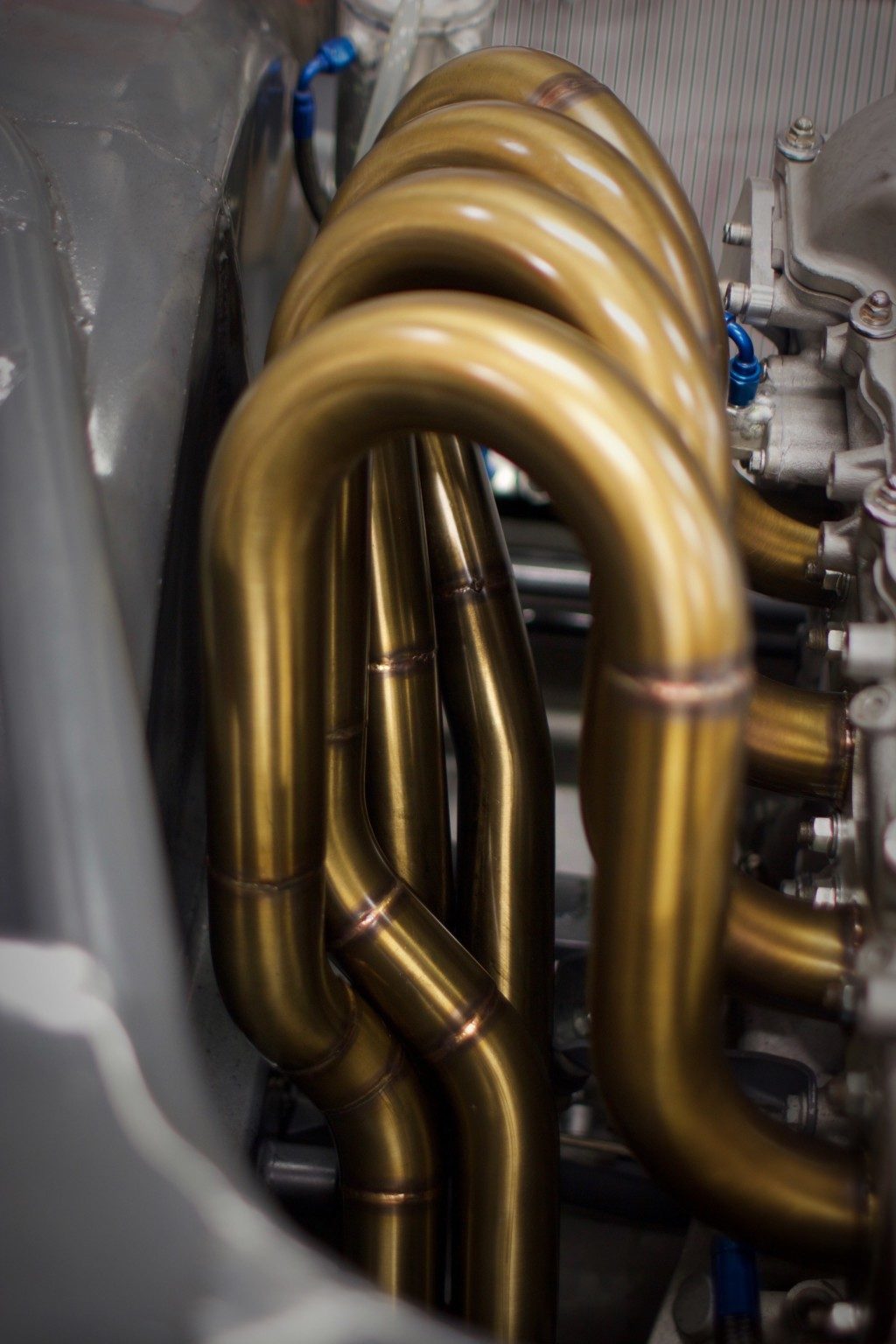

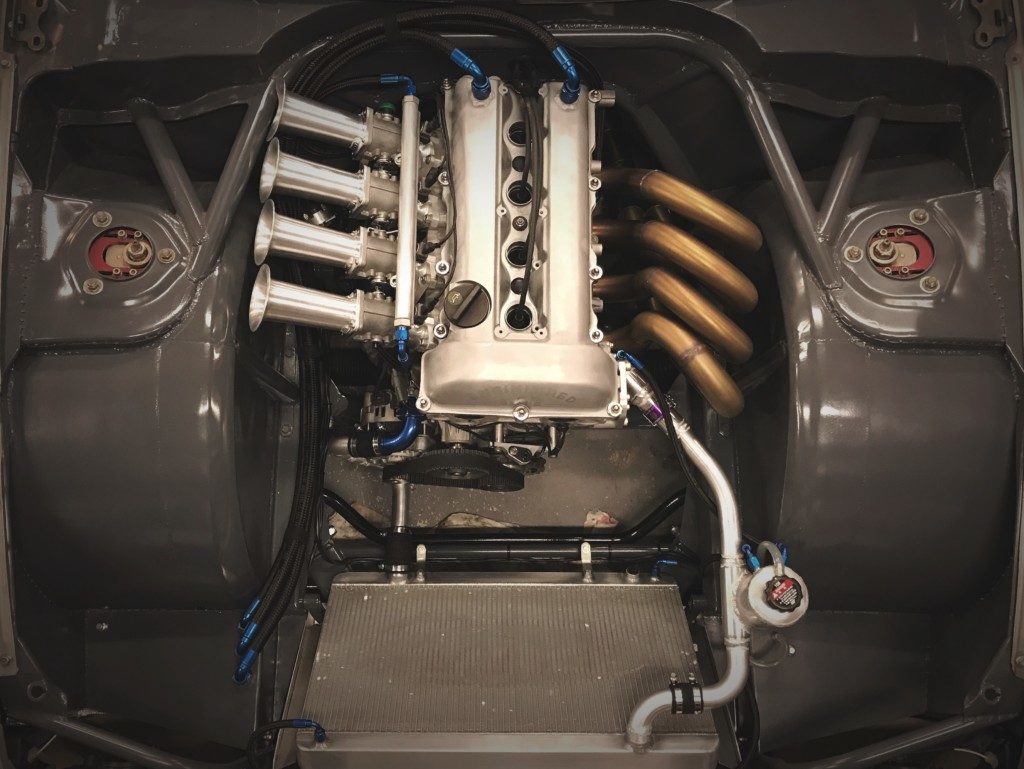

Before I get to the cooling system lets just take a minute to appreciate these headers.

The heat has really played its part in making this my favorite part.

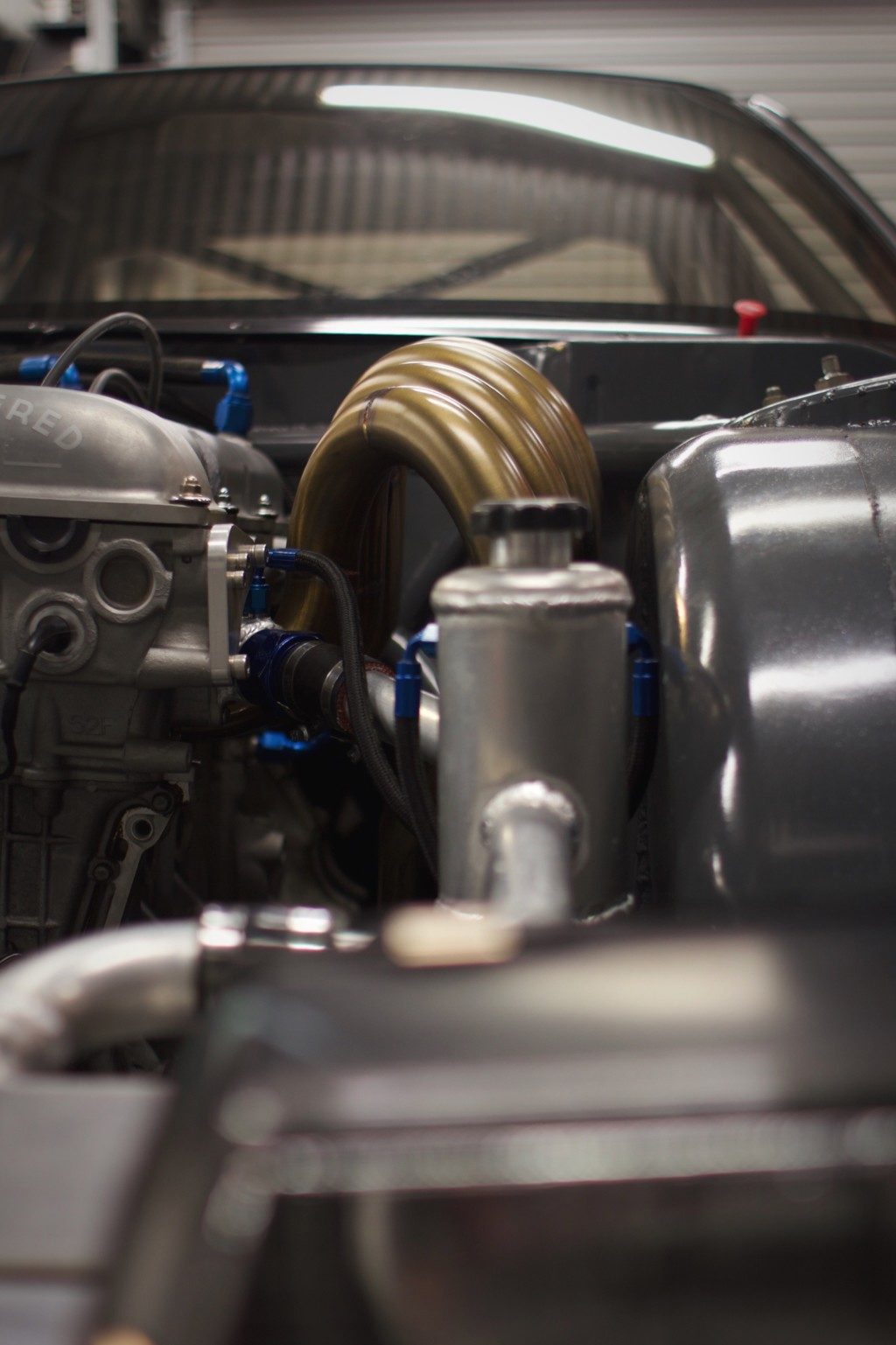

So back to this cooling story, while the car was on the dyno we had a huge problem with cooling on the initial run of the car. The PWR radiator was working so well that the lower hose was so cold that the thermostat refused to open, now in a normal SR20 with a heater this isnt a real issue because the heater takes the hottest water from the head, runs it through the heater core and then through to the back of the thermostat. To quickly fix the problem I drained the radiator and placed washers in the top and bottom hoses, these both had 6mm holes to reduce the flow, it wasn’t ideal as the radiator still worked so well that we didnt even need the dyno fans on for the power runs.

So I started thinking about it, I really needed a thermostat in the top hose so that I could properly heat the engine and get a true indication of engine temperature and control.

I decided to remake the entire top hose and header tank as I really wasn’t that happy with the welds I did on it originally. I also wanted to mount it further forward and also further off center to allow me to make the venting in the bonnet (when I get to that) a little neater. If you want the plans to the bender they are available here.

With everything now welded up I ran into a little trouble.

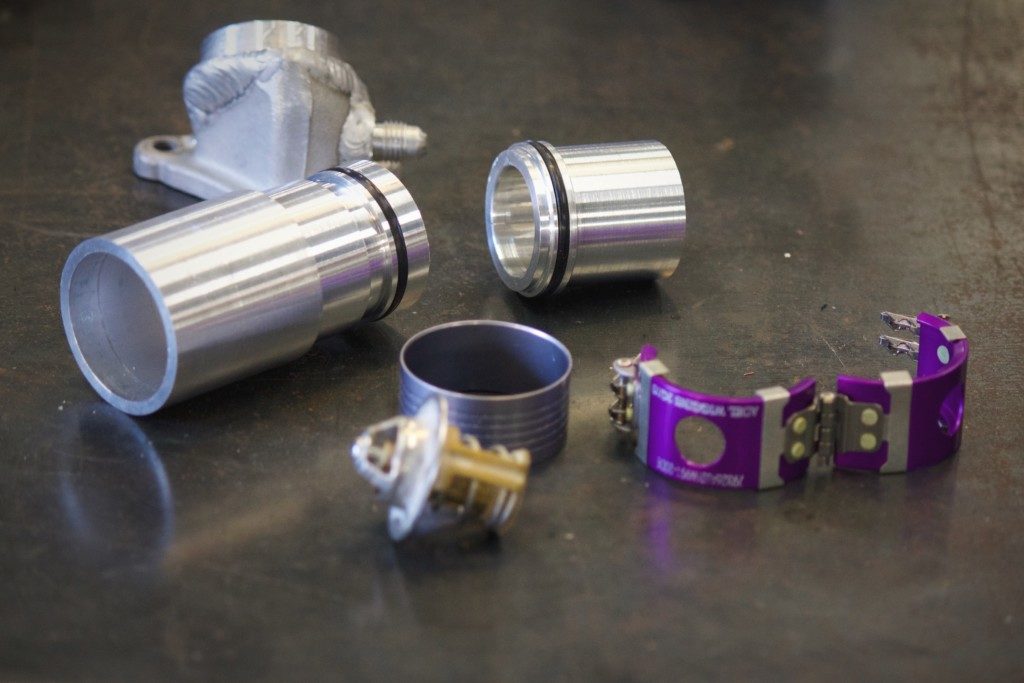

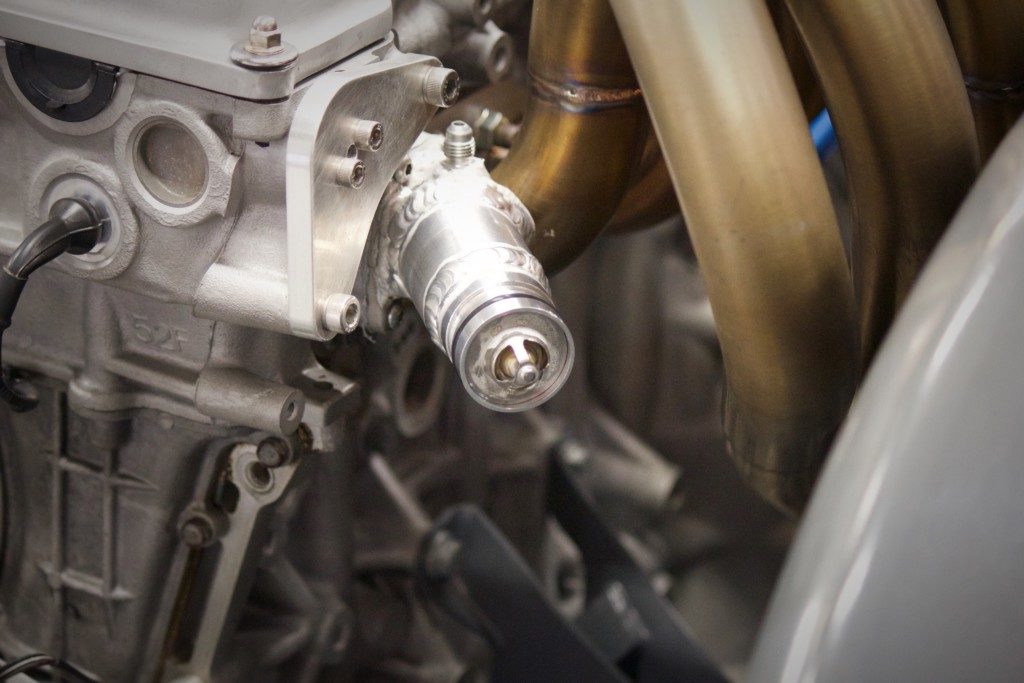

I toyed with the idea of running a normal thermostat in my home made Wiggins style clamp using an old blow of valve assembly, well it failed so I threw it in the bin and called the professionals.

A day after speaking to Ben at Hypertune this arrived in the mail.

Coupled with a little lathe work, some O rings, a 2009 KTM 450 EXC thermostat I was ready to go again.

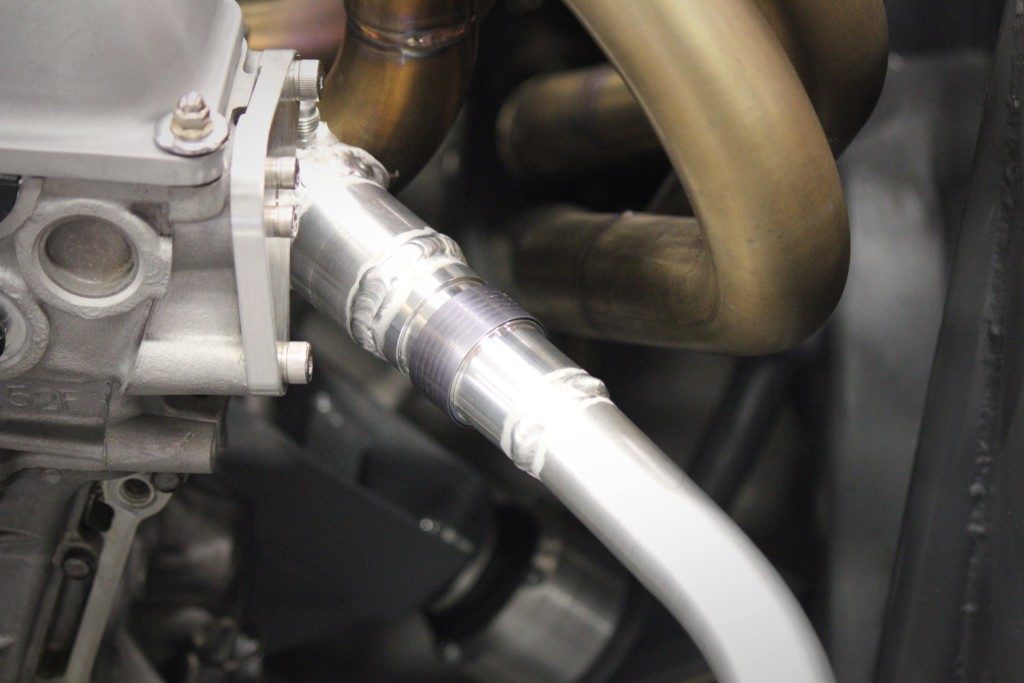

You would be suprised how much these flow, I did some tests with the kettle and a funnel and it was close to a dead heat with the factory Nissan item, when you think about it my 6mm washer would have flowed much much less.

With the header tank refitted I can now tack up the ends.

Wiggins clamps have a 4 degree misalignment allowance and with the engine flexing approximately half of that distance its safe to say I have the right tool for the job.

Some welding later and its all sorted.

Refit my lines and we are good to go!

I actually think I am ready to refit the doors, bonnet and take this thing out in the wild for some fun, its been a long time coming and I am pretty damn excited about it all.