I just want to say that it’s good to be back posting about cars and specifically this S15.

This year’s been a wild one to say the least and I hope you have stayed safe throughout it.

It has impacted me in many ways but none that I look back on in a negative light. The lack of travel has given me time to focus on my business and my passion which are ultimately now the same thing.

I am now operating Engineered To Slide full time and the online planning platform that we use could not have come at a better time.

The year hasn’t been without some setbacks though as my wife contracted breast cancer and went through a really tough time to get back to health, added to that we had a once in a lifetime tornado that removed a portion of our home that took 4 months to fix.

In this time I have put my head down and worked hard, focused on the long game and made the best of my own region by enjoying the things that surround me. With Melbourne locked down our coast line has been the most peaceful I have ever seen it, I bought a surfboard and made a point to atleast head out into our amazing oceans at least once a week.

Enough of the life stuff lets chat about what you came here for…. cars! more specifically the S15 project.

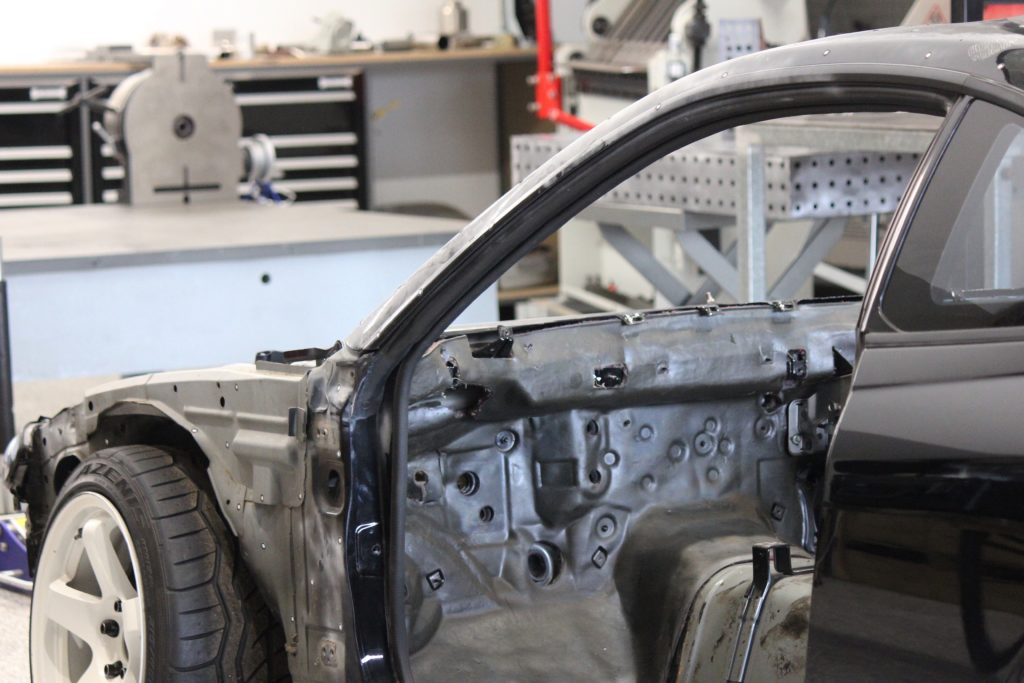

Im really enjoying this process and lets face it…. its been a long time since I have had the opportunity to take a chassis and begin this process from scratch.

Even the worst jobs (removing sound deadening) have been enjoyable.

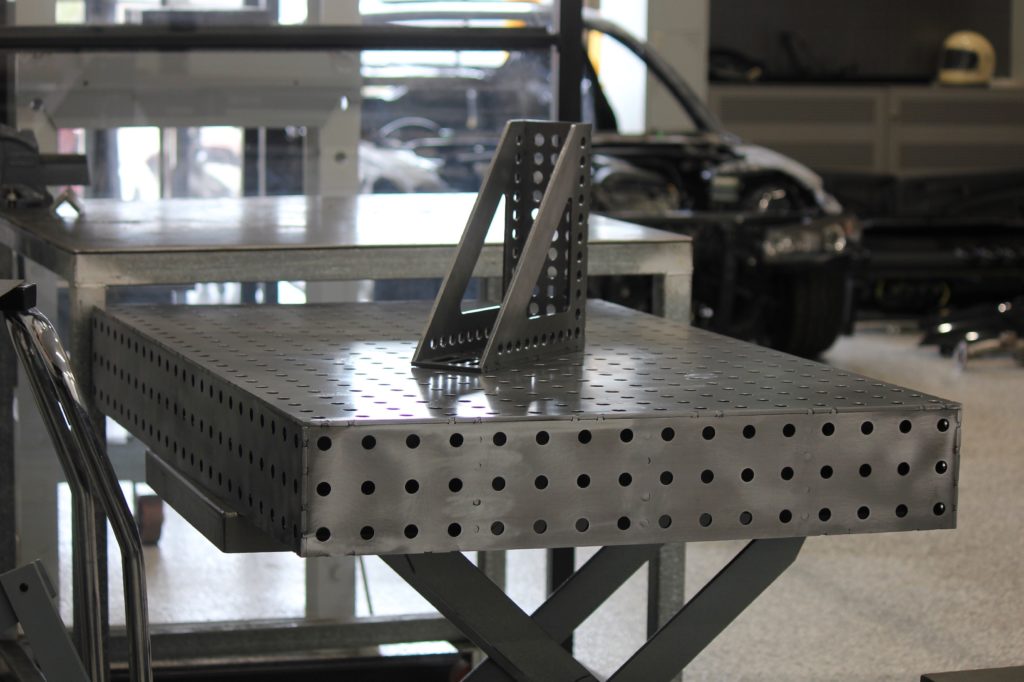

It’s all in preparation for the scanning process which will form the 3D model of the chassis that will allow us to draw the roll cage to complete FEA (Finite Element Analysis) to plot the loads that the FIA use to approve roll cage design.

It’s a process that I am excited to learn and it’s a real snapshot into the high end level motorsports that I have always aspired to reach.

This and many other projects are happening here at Engineeredtoslide to create a platform that will fast track our your progression through the world of motorsport fabrication. DIY tools, DXF plans and step by step worked examples all coming from 20 years of experience is something that I know many people will enjoy and to be doing this full time is a dream come true.

As always thanks for reading and I hope you can stay productive and positive in these trying times.