It’s been a busy couple of months, since moving into my new space I have been adament not to waste any time during the setup phase.

In the first two minutes that I laid eyes on this space I new what I wanted it to transform into and piece by piece its happening.

The central table would be the feature directly under the office that sits above.

This surface table is what dreams are made of!

Thats 4 tonne of steel that was cast in 1965, I had it sand blasted and then primed so that it could sit outside until the NuLook floor treatment was done. With the floor and the table in I was starting to make real progress.

With the surface table in it’s place I could get to work building the office upstairs.

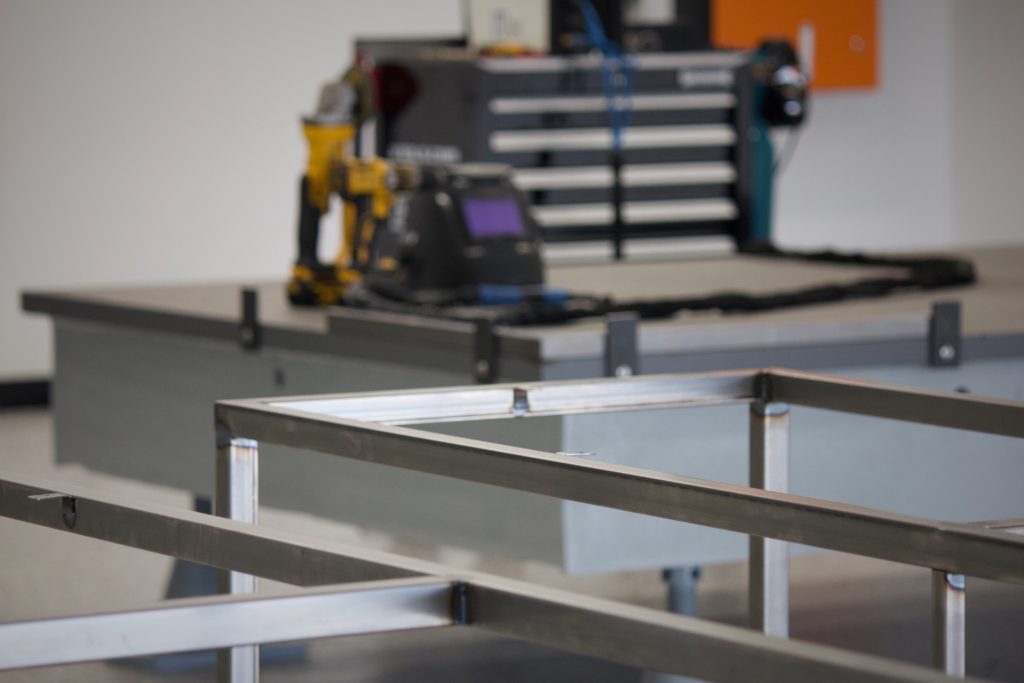

Using the surface table for the very first time was an amazing feeling. For the past 10 years I had been building things off the floor with questionable accuracy and now I have a completely flat and square surface that makes building things square a breeze!

I added some tabs to the threads that were in the side of the table, it made life even easier to make up the ERW Frames for the upstairs office furniture.

Theres nothing better than working for yourself, when the day calls for more hours you can just make it happen.

Believe me this setup phase has been a busy time.

I took a trip up to Melbourne in the van to pick up these sheets of furniture grade Birch Ply, 18mm and 32mm.

The thickness of the ply matches the ERW tube I used for the frames. It creates a really simple finish that looks great.

I no longer had to check and recheck if things were square, it saved me a bunch of time.

That coupled with the precision of the SWS TIG welder meant a neat and clean straight off the table result.

The joys of TIG welding.

With the tables complete I could start to think about the smaller items.

I had another cracked TE37 that I made a side table out of.

I used 8mm solid steel rod to make the frame, pretty happy with how it turned out.

I ordered all my chairs, 10 in total. 2 arm chairs, 2 office chairs and 6 table chairs.

I used some satin black spray cans to finish off the tables.

Then scattered the things I love to make me feel at home.

Oh and a few two wheeled air fresheners in the corner, the 1951 Drag Triumph and the 1969 Rickman Metisse.

Overall I am really happy with the results!

On a very modest budget (the entire 50 square meter fitout was less than $3k) done by myself in just over a week is pretty impressive. The shops up and running and you can find the merchandise here.

I can’t wait to go to to work every single day.

It is the perfect environment to progress Engineered To Slide into this new era.

Taking my love for cars, motorcycles and the way they are constructed to the next level.

Whats next? The workshop fit-out down below.