They are two very different worlds, cars and motorcycles. I know a bunch of motorcycle enthusiasts that have absolutely no interest in cars and vice versa.

Through my social outlets I waver between two and four wheels with different events and builds that I am undertaking.

In recent times I have combined my love for both cars and motorcycles, namely my American adventure where I built my 1955 Panhead that took me to the Californian Hot Rod Reunion, SEMA, Petersen Museum and a bunch of other amazing destinations.

There were still divisions between the two and I just couldn’t shake the idea of blurring the boundaries and completely mixing my two passions.

Spurred on with the fond memories of previous cross automotive pollination (minitruck and drift car) I just needed the opportunity to make the vision a reality.

The opportunity came about when I got the call up to do some riding for my friend Dean Walters while he photographed a custom BMW R Nine T Racer built by BMW.

About half way through the day I was sitting in Melbourne traffic looking at Dean on his R Nine T Racer, right there and then a light bulb moment occurred.

This bike with its timeless sleek style, single sided swing arm, simplistic air cooled boxer engine and aggressive stance would lend itself perfectly to this crazy idea.

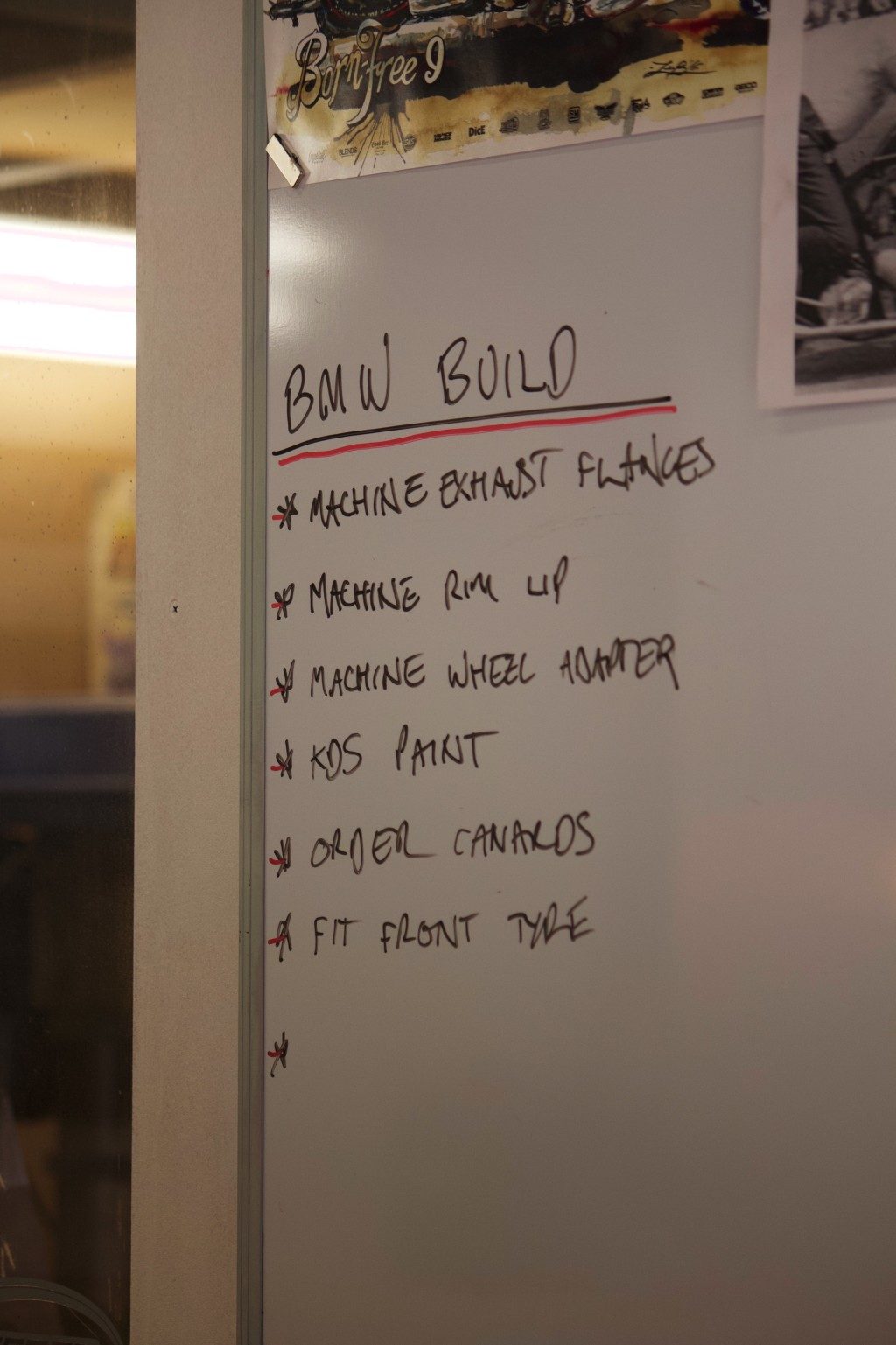

I asked Dean if I could borrow the bike for a night and do some measurement’s, I rolled it into the garage and sat it next to my RPS13 Drift car, took down an old cracked TE37 from the tyre rack, wrote out a small plan of attack and began to get excited about a circa year 2000’s drift inspired BMW R Nine T Racer.

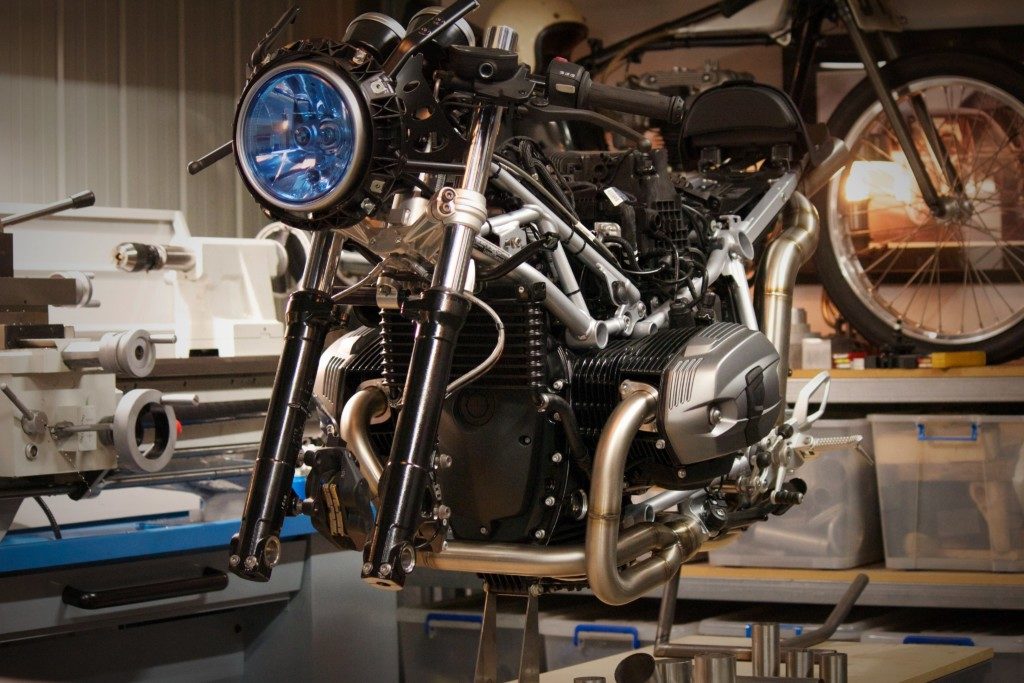

After a visit to BMW HQ in Melbourne I was coming home with a brand spanking new BMW R Nine T Racer in the back of the van.

The guys at BMW saved me some time by removing the exhaust and the rear lights so that I could get to work right away on making this idea a reality.

This build was simple in the fact it was a brand new machine, a very capable and well built one at that, all I had to do was add my style, a big enough job in itself.

There were three components that I had to nail, the first was the TE37 rear wheel, this wheel was actually retired after being used for many years on my RPS13 Drift car, 7 years ago I cracked the inner lip at WTAC on the entry to the straight, the rim had been used a hose reel ever since.

Being 18×10.5 +22 with a PCD of 114.5 I had to do some calculations to make it suit the BMW, but first I had to find a manufacturer that produced a 200 wide 18 inch sportbike tyre, not the easiest of tasks when most sportbikes are 17 inch.

After a stack of searching I found what I needed, that being Shinko’s 011 Verge 200/50/18 rear tyre and matching 120/60/17 front tyre. Things got even better when Shinko Australia invited me to pick them up from the warehouse and check out the amazing inventory of tyres they had in stock.

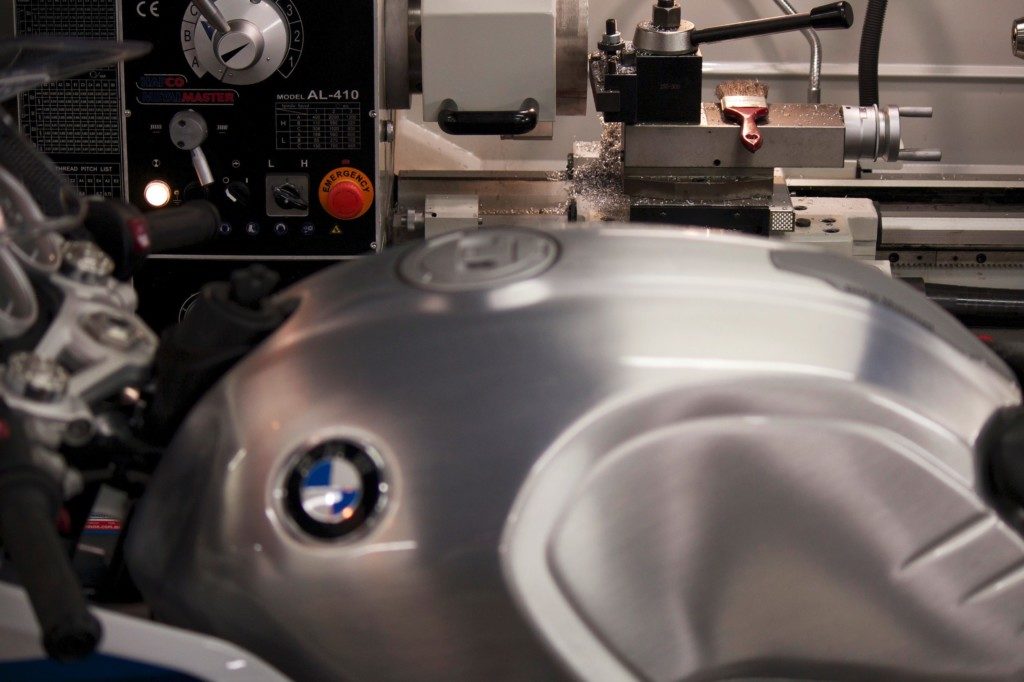

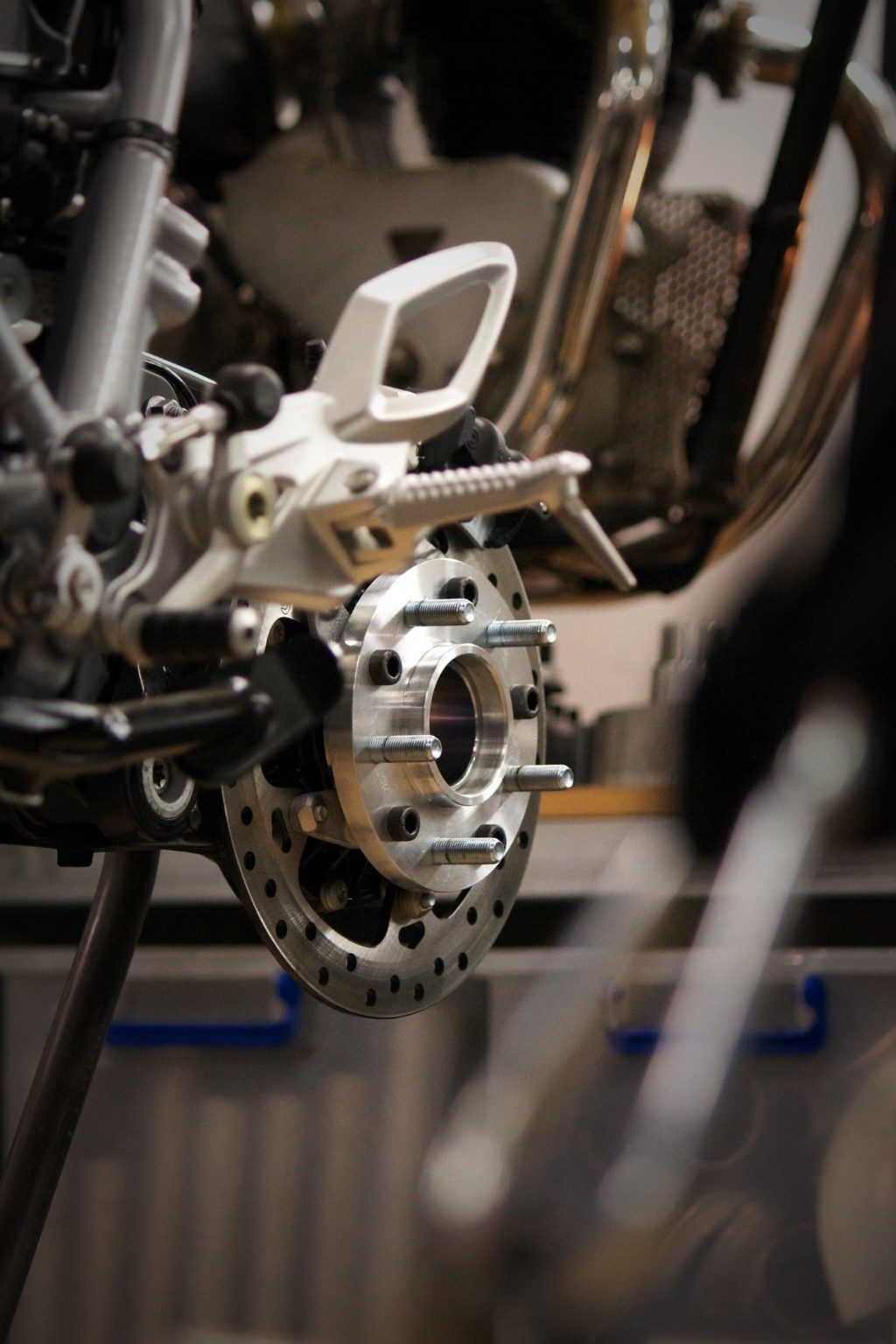

So my new tyres were sorted, now the hard bit, make the rim suit the bike. I spun up an adapter on my lathe that was 13mm thick that centered on the BMW hub and also centered on the TE37 rim. From there I drilled 5 holes at 120pcd to bolt to the BMW hub and then another 5 holes at 114.5pcd to house M12x1.25 studs for the TE37 rim.

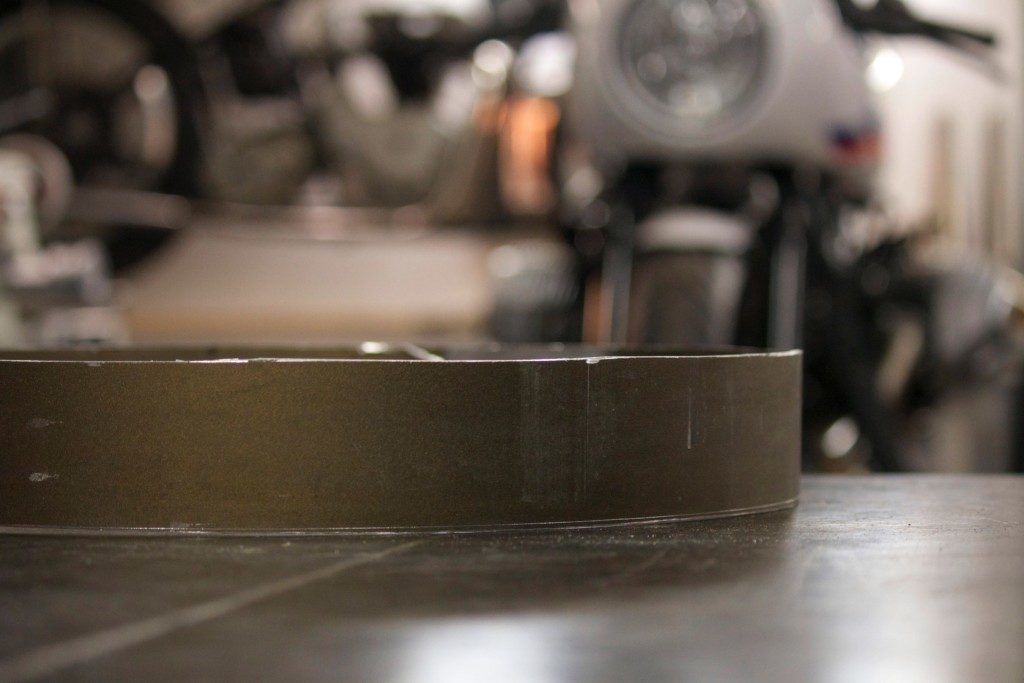

With the adapter sorted I could now work out the width of the rim, Shinko said that a 6.5 inch rim would suit the 200 Verge tyre, after measuring the rim I concluded that the width would be 6.5 inches and then worked out where to cut it.

But first I had to fix the damage to the rim, after spending a lot of time filling dings and cracks then machining everything back smooth it was time to cut it in half.

I chose a section that was the thickest and then overlapped the two sections by the amount needed to bring it from 10.5 inches to 6.5 inches wide.

After a few tacks it was time to mock it up on the bike. It just looked so good sitting up on the bike and the biggest piece of this project was almost complete.

I slowly heated up the rim and prepared my SWS Alumtig 200 for the biggest alloy welding job I have done. Section by section I added weld to both the inner and outer, slowly moving around the rim and offsetting the heat affected areas, as the amount of area unwelded diminished so did my nerves, the meticulous preparation was now paying off and I had just about made a TE37 motorcycle rim.

With the wheel completed it was time to remove the bodywork, the tank, the front wheel and start mixing up the paint for the ultra talented and all round nice guy KDS to work his magic. I took another wheel and a what was left of my broken rear fender so that Karl could match up the paint.

It took some customizing but Karl nailed the colour match on both the bodywork and the rims. TE37’s are anodized and extremely hard to replicate with paint, after a matte clear Karl had this rim looking like new.

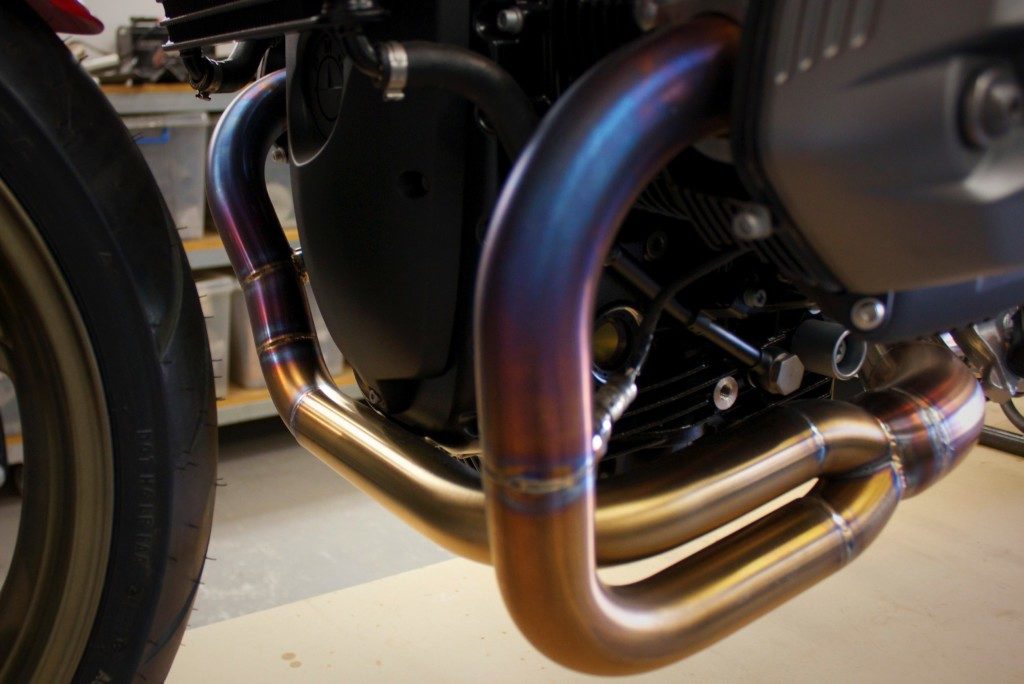

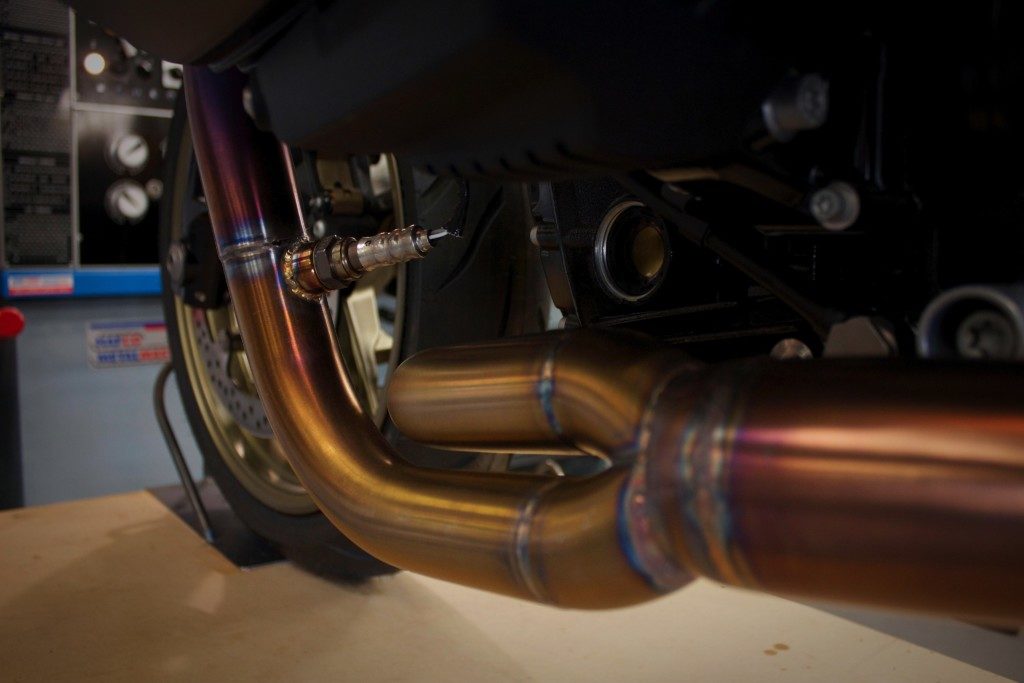

While the paint was drying I whipped back home to make a start on the exhaust. Another huge aspect to this build, I wanted to emulate the RPS13 “Blast Pipes” that I had built for it with a pair of 2.5inch versions for the R Nine TE.

I set about making a very automotive inspired header pipe with a twin Stainless 1.75 inch primary’s leading into a merge collector that would begin the single 2.5 inch Stainless section that really frames that TE37 rear wheel.

The rear section breaks up into two 2.5 inch blast pipes exiting out the back and finishes off this circa 2000’s drift inspiration.

It was now assembly time, if you ever get the chance head into your BMW dealer and take a look at the quality in not only the complete bike but the little things like the fasteners on these R Nine T’s, it makes the assembly process a real breeze. In fact you would be hard pressed to find a more customize-able machine on the market.

As the bike took shape I constantly took a step back to appreciate the evolution of the idea becoming a reality.

Just a few months ago this BMW shared absolutely no DNA with the RPS13 it was meant to represent, fast forward to this moment and this BMW is now a complete reflection on its 4 wheeled inspiration.

It was time to make some noise and get these pipes colored in, I have built a lot of exhausts now and love the process of coloring them. I make sure the entire exhaust is clean inside and out, I fit my cotton gloves and reasemble the exhaust on the bike ensuring there are no finger prints or fluids on the stainless steel. I then fire up the bike and let it idle for a minute or so. This begins the burn in process and the stainless starts to change colour.

As the silver turns to gold, then to purple, then to blue I give the bike a few revs to get that colour completely into the header pipes, once I am satisfied with the appearance I switch it off and let it cool down. For some reason this colour wont change much with general riding and it seems the first burn in is the most important one to achieve a beautiful colour on the pipes.

Continuing the theme of recycling broken car parts I made up some small canards to further tie in the two worlds.

They just add those small relatable touches to the overall design.

With the bike complete I can now get it out for its first test run.

Why not make an afternoon out of it and bring its inspiration along as well.

It looks incredible sitting next to the RPS13 Drift car.

I couldn’t be happier with the results.

It is the combination of all the small touches that make the overall finish.

As I write this I am on my way up to WTAC in Sydney with both the RPS13 and the BMW R Nine T Racer, I am proud of my achievements and want to thank BMW for the opportunity to turn this vision of mine into a reality.

Pingback: The TE37 Goes Moto

Pingback: The BMW R Nine TE Racer | Engineered to Slide - Chop Feed

Mohammad Alajmi

Hi, hard to find your project,

I’m Mohammad

From Kuwait 🇰🇼

And I need 2 wheels front and rear

For my bike .

Thanks