I have always followed my heart with the cars I have built, every little detail reflects what I believe my perfect “street car” to be.

But what makes life a little difficult is that none of my cars can be registered due to the laws here in Australia, what makes things even more difficult is the cars I have built don’t really fit into any race category or class.

I have no issue with that at all because every time I look at what I have built I am comforted in the fact that I haven’t gone away from my ideals to suit some race category that may or may not be around forever anyway.

My goal in 2018 was to drive all my cars on the track, yes there is a lot of work that goes into just getting to the track but when I slip on the helmet and strap myself into the car it’s all worth it 10x over.

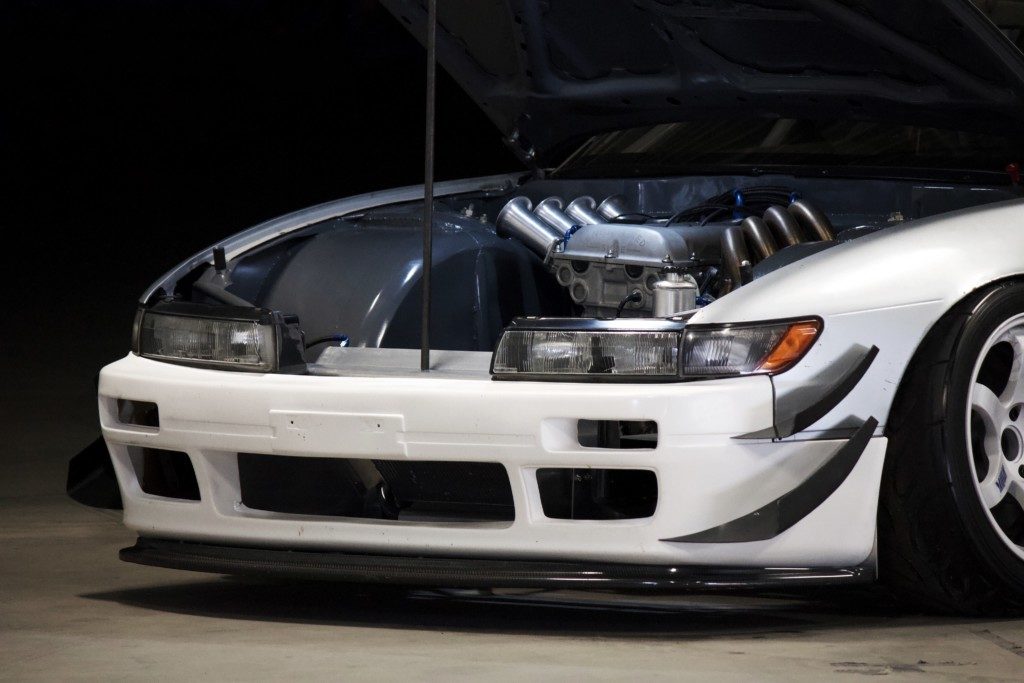

So my PS13 works on the dyno, it works on the street, how will it go on the track?

I started thinking about it too much, overthinking the situation, then something switched and I asked myself why couldn’t I just book a test a tune day at Winton Motor Raceway, just head up there by myself and use the day to enjoy spending time driving my creation.

So that is exactly what I did, $160 for the track day, $75 for the annual AASA Licence, I loaded up the car into the trailer, set my alarm for 3am and set off to Winton.

Unloaded and signed in I unpacked my tools and setup my garage for the day.

I had everything I needed to do just about any changes to the car.

Driving the car on the street highlighted an issue with the shifter, the length and the dogleg style of it made the 6 speed extra tricky to find the right gears, I was prepared and adapted a stock 5 speed shifter for use for the day.

I removed all wheels and made some adjustments to the suspension, did a quick bolt and alignment check too.

I also raised the car about 15mm all round.

It was nice having a heap of room and no one around to just make sure everything was ready for the first session.

See what I mean about room?

I wasn’t the only one there, about ten garages up was this little V8 Powered MG, he was also there alone to spin some laps, we helped each other out when we needed it.

The “tin top” class I was in had some heavy hitters in it.

Production race cars dont come cooler than a GT3.

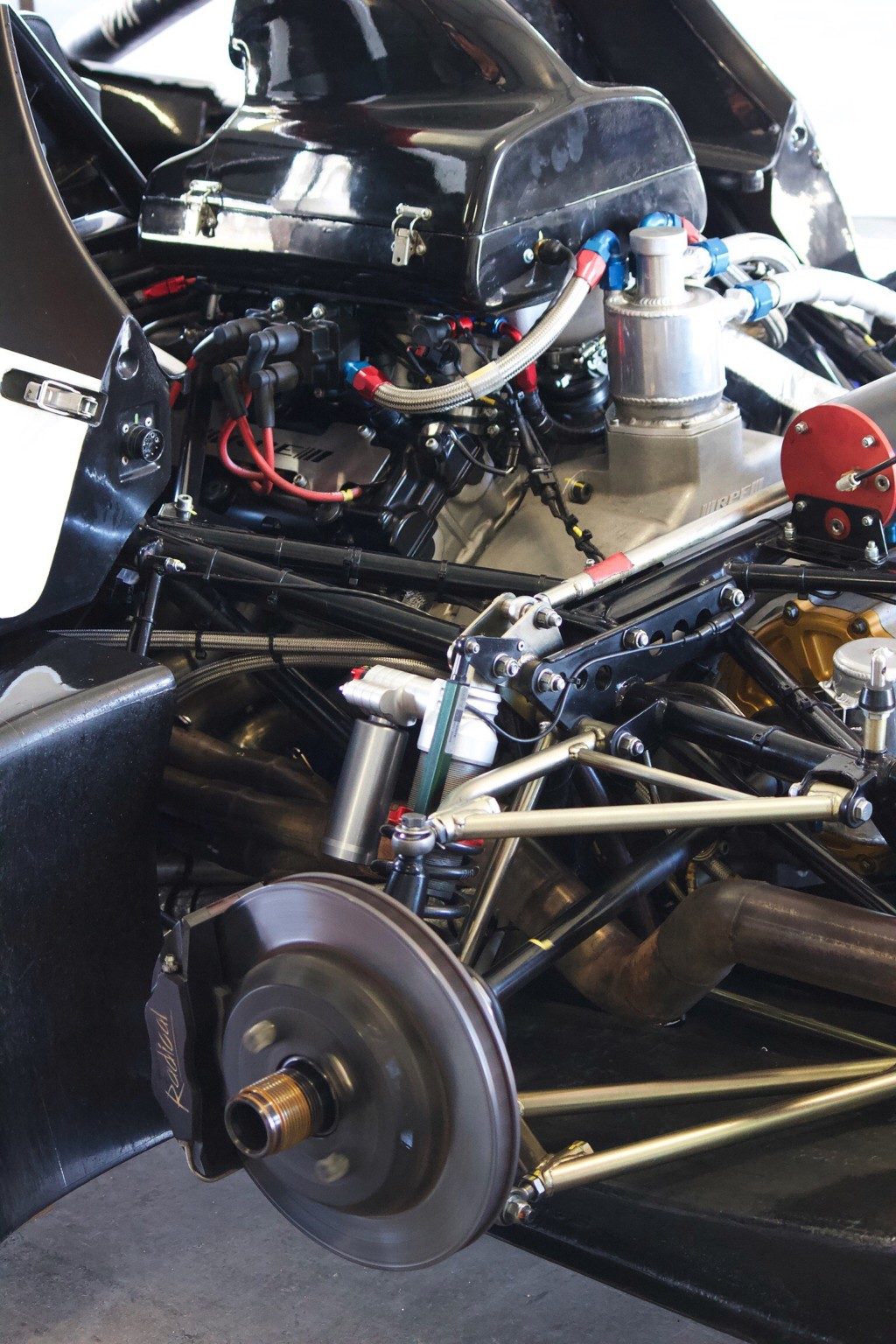

There were 2 Radical V8’s in attendance aswell.

I never get tired of looking at these engineering masterpieces, everytime I look at these things I learn a thing or two.

I did my final checks and suited up for session one.

I wrote a list of things to do and check -Adjust Brake Bias -Watch Oil Pressure -Water Temperature

Rolling out to the track in session one was exciting, everything felt really good. I ran through my list and started gaining pace.

I knew Winton like the back of my hand, I had done so many drift laps around this place over the last 10 years but this was like going back to school for me.

I had never driven on semi slicks either, the A050’s were incredible, with a little heat in them I started finding my lines and testing my limits, I kept one eye on the track and one eye on the oil pressure, I have never trusted this sumps pickup and the reason why I am here with a stock bottom end.

Sure enough with the longer higher G forces the pickup started to become starved of oil. In session 2 I added another 500ml of oil and the problem went away but it was to be a quick fix to get me through the day.

In session three I really started pushing the car and felt completely comfortable with it, when I first decided to build this car into a low tune NA grip car I wanted to simplify everything, I didnt know if my decision to remove the power steering would come back to bite me but I can confirm that it feels amazing, the feedback through the wheel is something else, heightened by my custom knuckle design, chromoly suspension arms, rose joints and tube crossmember.

In my quest to simplify everything I designed my cooling system to be fan less, in the 28 degree ambient temperatures on the day I could drive the entire 25 minute session at 100% and the water temps didn’t even rise above 100 degrees. Carrying on the “I dont need it” attitude I kept an eye on the oil temps, they too ran no hotter than 70 degrees on the gauge.

Between sessions there wasn’t a lot I needed to do, I had my BMX with me so staying entertained wasn’t an issue.

I couldn’t wait to get back on track for the last session, this grip driving was addictive and I wanted to improve my laps, I didn’t expect to be doing this on my first day but I found it extremely satisfying to take a different line through a corner and subsequently pick up so much extra speed down the following straight that I needed a higher gear than the lap before. The S15 6 speed gearbox combined with the 4.9 diff gears made the car feel so fast, I think in the last session I spent over 20 minutes over 5,000rpm.

Maybe that was a little too much for the stock oiling system to handle….. In the last session I completely lost oil pressure and shut it down immediately. I was able to roll into the pit lane and then roll it on the starter to get over the hill and into my pit. My day was done and I wasn’t at all unhappy about how it ended.

I hung my suit up to dry and got my camera out for some photos.

I couldn’t be happier with this car and it’s first time on the track, it feels unbelievable, for a 117kw at the wheels car to feel like this is a testament to it’s setup.

I had the hardest time deciding how I was going to build the motor, at the time I felt like I had missed an opportunity to make this car something special, to use a $100 bottom end and then engineer all of these nice things around it seemed like a bit of a cop out. But now I am completely happy with my decision, to be lapping around having the time of my life with very little to loose was a great feeling, I could concentrate on my driving and the setup of the car without too much care. I mean if I had of gone down the 2.35 92mm stroker avenue then those oil pressure issues would have spelt the end of the day for me. I just wouldn’t of risked it.

I will still eventually build a bottom end for this car with high compression pistons (because the heads setup for that exact thing) but only when the oiling system is improved.

How will I do that? Well first I have to troubleshoot what went wrong? I am half way through pulling the oil pump out but early investigations seem to point to a broken or failed oil pump, I have a suspicion that it’s to do with the fact that I made my own crank balancer that doesn’t actually balance, therefore the high rpm harmonics have dealt a deadly blow to the oil pump.

That fact along with the poorly designed pickup in this sump all points to a dry sump system being the ultimate fix. To ditch the factory oil pump and pickup, to ditch this sump and have an external oil pump, a greater amount of oil in a well designed tank, more power and reliability seems like a logical step.

But for now I will fit the spare oil pump and head back to the track for some more good times, then over winter I will pickup a dry sump oil pump, dry sump pan, an oil tank and get to work creating my ideal oiling system, while I am at it I will build a completely new fuel tank and then head back to the track.

Once all of that is done then then I think I will save up for a Quaife Sequential transmission (like I have in the Hilux) as I think there is a lot to be gained from fast shifts (not to mention I struggle with the close gates in the Nissan 6 speed) but that is way down the track.