A few weeks ago I wrote this post without publishing it, I hadnt made up my mind what to do with the engine in the PS13 at that time so I thought it may be worth posting so you get an idea of where I am coming from.

Firstly I want to give you a little history lesson on my involvement with the SR20 engine, at 17 years old I had a Ford Escort RS2000 Coupe (yea I wish I still had it) at the time I was head over heels with it, it was my first car, my first ticket to a world of open road freedom, I would draw on its rally heritage and get it as sideways as I possibly could on my local country dirt roads.

I would read magazines and it quickly became apparent to me that an all aluminium 16 valve turbocharged engine would transform this car into something amazing, having next to no mechanical knowledge I obtained a quote from my local mechanic to supply and fit an SR20 motor and gearbox into my RS2000, I remember reading the quote and it came to $14,500, that was $14,000 more than I had at the time so I regrouped and decided to just wait it out.

The year was 1999 and I somehow managed to obtain some footage from Japan of drifting at Sekia Hills, up until this point I didn’t even know there was a motorsport that involved so much individual style and spectacular driving, the S13 SR20 was the king of the competition and I was hooked.

Long story short I took out a personal loan and my first SR20 powered 180SX was firmly in my possession, after winning the very first Drift Nationals ever to be held in Australia this car had a fairly short life of only 3 years, that 3 years was an intense learning curve of many of Motorsports fundamental skills, driving, maintaining, repairing, financial hardship and long long hours learning the hard way.

Just as the loan was repaid the chassis went to the scrap yard to be crushed, the SR20 engine was still in perfect condition, a testament to its build quality, still in its internally standard trim I was blown away by how versatile these engines can be. With an empty garage and a full S13 driveline at my disposal I was in the market for my next chassis. I found out that a friends dad had an AE86 for sale, I picked it up and made plans to fit the entire driveline into this chassis. Just as I did I found my two tone S13 Silvia for sale, it was perfect, it had everything I ever wanted.

The AE86 went on the market and I picked up the two tone PS13, the driveline eventually went into the S13 and served me well for many events, I had a cheap 80mm throttle body on my self made plenum and it ended up braking the butterfly and ingesting a screw into the 4th cylinder, I remember I was driving it to work and heard a rattle, I shut it down asap and then pulled the motor out when I got home. I thought it was destroyed but after pulling the head off (for the first time ever) I could have just removed the screw from the spark plug hole and kept driving it, there really was no other damage other than a few little pit marks on the crown of the piston.

This is where I went off track, the V8 conversions were almost unheard of at this time, a friend had an Chev LS1 for a good price, I fitted the motor into the car and then started looking around for gearbox’s and all the ancillaries to make it all work, I went to the track to help pit for a friend at that time and there was another LS1 powered S13 drifting, it was the most boring this I had ever seen, sure it made plumes of smoke but when you close your eyes I just couldn’t feel the influences that made me fall in love with the sport in the first place. Its the perfect motor for the right person, that person wasn’t me.

I got home and ripped the motor out, selling it for a profit, then looked at what I could replace it with, it had to be an SR! I ended up finding a guy in WA that just had a motor built at a shop called C Red, he decided to go overseas for a few years and needed $$, the motor was still wrapped and crated from when it came from the machine shop, with $12,000 worth of receipts I had it shipped to me for $5,000.

This was to be my second SR20, its been a great motor, has all the right gear and currently resides in the Hilux, years of punishment and currently making 336 rwkw, the third SR20 resides in my RPS13, its internally standard and has made 255 rwkw since 2008 competing and driving in the majority of events and tracks in Australia.

The only damage I have ever done to an SR20 is that ingested screw I mentioned earlier and 1 broken rocker from a severe over rev in the Hilux the time I busted my RB25 gearbox, that’s 15 years of predominantly fault free service.

This brings me to SR20 number 4……The SR20DE…….. The choice to do something different with this motor was an easy one, doing the exact same thing would result in the exact same outcome, I wanted to learn about internals as I have never had to do any internal work ever before, with a high output naturally aspirated motor its all about internals, you cant just stuff more pressure in the inlet and make more power, its so much more than that.

So I start looking at my options, the engine that is sitting in the PS13 at this current time is internally standard, a $200 engine purchased off a friend, its in great condition and would be the perfect recipient for a rebuild, but what will it take to rebuild and does it really need to be rebuilt?

In my mind theirs really only two options that I have.

Option 1, leave the bottom end standard, use the Nismo 0.5mm head gasket, use my ported and flowed head with oversize valves, get it shaved by 1mm (a common practice by racers to bump up the compression ratio) bolt it down with new head studs, add some larger cams, in my case these are Tomei 270 12.5 Pro Cams with the stronger Tomei valve springs and solid lifters.

Or

Option 2, If I was to pull down the bottom end the price difference between a mild upgrade and a serious upgrade isn’t all that different. To make power in a naturally aspirated engine it comes down to mathematics, there are many factors that I don’t really need to get into but theirs one that you cant disagree with CAPACITY! After months of research I keep coming back to stroker kits and their influence on power production. The SR20 in its natural state is 86mm bore and 86mm stroke, if I am going to go a larger bore and stroke I might aswell go as far as I can.

I want to keep it a square engine, that means the bore is the same as the stroke, the largest bore and stroke you can go is 92mmx92mm, this is achieved via Darton sleeves that essentially require’s the entire center section of the SR20 to be machined out and replaced with 4 specially stepped sleeves that are pressed into the block. These are then bored out to 92mm to accept custom pistons of any compression ratio you choose.

The specially made 92mm Billet crank is then fitted into the block to achieve 2.45 litres of displacement, sounds like a pretty wild SR at this point, I started looking around at purchasing the parts needed to complete this locally, I can get the pistons, sleeves, rods, crank, then organise the local machine shop to do the work with the added cost of having a torque plate built for honing the new cylinders, then clearancing the block for the extra swing of the rods.

Its a heap of parts, a lot of shipping costs, a lot of machine work and a lot of trust instilled into the machinist that they complete the work to the highest standard.

Its worth mentioning that I am not interested in the VE head, I love the S13 head with its upswept inlet ports, after a decent amount of time spent porting and flowing, resizing the valves and selecting the right cams the VE head seems like a more complicated addition to what is a fairly simple motor, again it has its place but that place isnt my garage. The one thing I do love though is the rail that holds the rockers, if their was some way of doing this to an S13 head I would move mountains to make it happen, having only ever dislodged one rocker in 12 years its not high on my priority list.

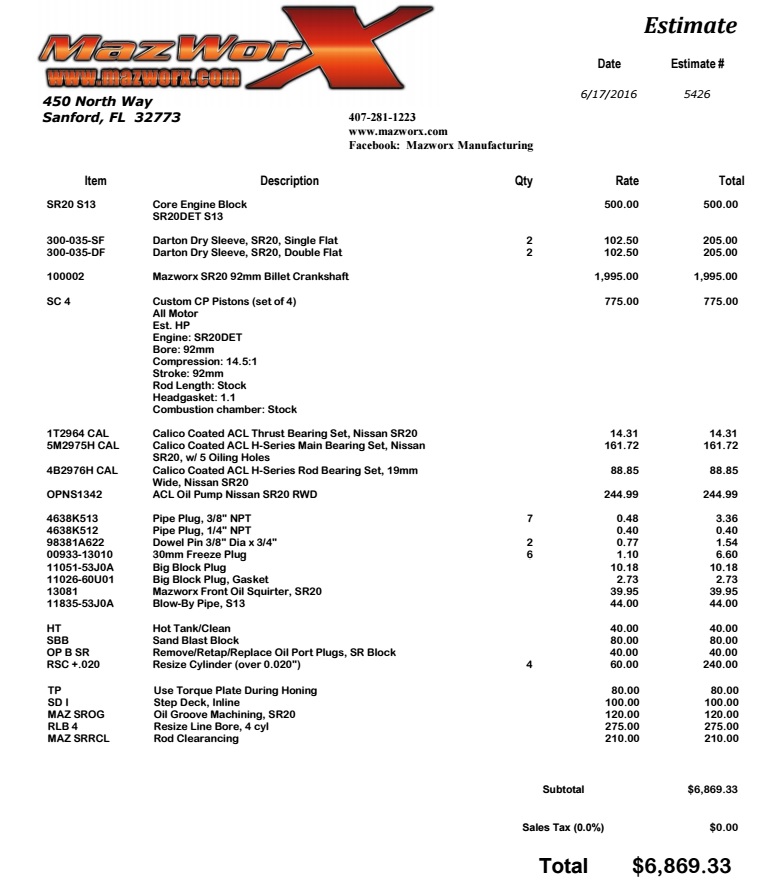

So at this point option 2 is looking pretty expensive, I decided to weigh up my options and put a figure on what it will take. Mazworx is the king when it comes to SR20 engines, they have designed and built the highest HP SR20s in the world, as far as trusted machine shops go they are a one stop shop, they have all the parts, the skills and the reputation. After a few emails to Mazworx we came up with the supply of a 92mm Darton sleeved S13 block with a 92mm billet crank completely assembled with all new components with shipping to Australia for a little under $7,000 USD.

At today’s rate it would be roughly a little over $10,000 AUD once I get taxed on arrival, I estimate that you could possibly make a little over 300hp from Option 2, how much power will Option 1 make? Probably around the 250hp mark. Is it worth paying $10,000 for 50HP? Would the difference be large enough over the life of ownership to really warrant the investment?

Part of me wants to experience what a large capacity SR 2.45 is capable of, an extra 50hp of naturally aspirated power is a lot different to an extra 50hp on a turbocharged motor, the ultimate engine in my ultimate chassis, but the other (older wiser) part of me says its stupid to spend 10k for 50hp.

This is the world of NA power production on small capacity engines, why don’t you see many highly tuned SR20’s that are naturally aspirated? Its simply far easier to have a turbocharged SR20 that can comfortably make 400hp for decades with standard internals.

But then again where the fun in doing something that you have done before, might be time for a garage sale?

So a couple of weeks have passed since that post, I thought a lot about this car and the direction I want it to go in and have decided against rebuilding the bottom end into an SR2.45

Why? Well the stakes are just too high, for one I dont have 10K just laying around and if I did there are a lot of other things in life that it would be better spent on than 50hp.

Another factor was the oiling and harmonics department, if I had a $10,000 bottom end then I would be stupid not to run a dry sump, proper balancer and the list goes on. I would also be a nervous wreck every time the car hit the dyno.

So what does all this mean? Well I am sticking with my $100 bottom end, bolting on the parts that I have and setting out to have a good time in what will probably be an under-powered car, but when I think about it the slowest car I ever owned was my Escort RS2000, ironically it was possibly the funnest car I ever owned. You know that old saying “its more fun to drive a slow car fast than a fast car slow”

So anyway, that’s me overthinking the situation in the 8.5 hours that I have to spend at work each day and this is the actuall work I get done in the 3 hours after I get home.

My list of jobs to do with the motor in was diminishing, I always hate pulling the engine in and out, with the Hilux I spent some time making some tools (in that case a neat little trolley) to make my job easier. In this case I used the hoist, my workbench on wheels, made an engine cradle and a sling bar to drop the motor out.

It made my life easier and allowed me to drop everything off the chassis with the simplicity of the hoist control.

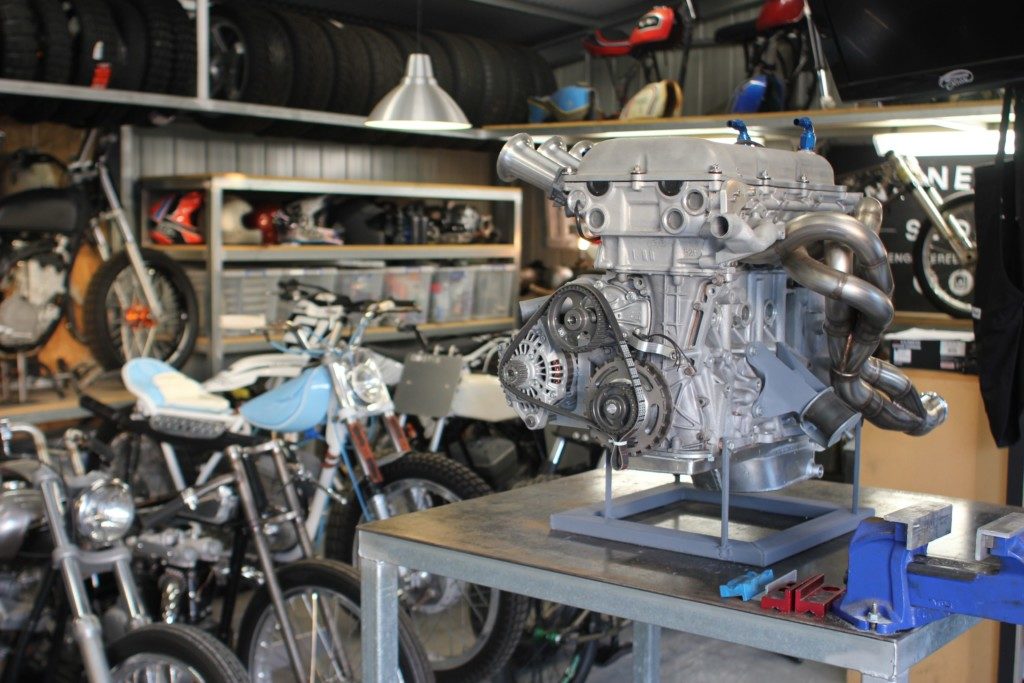

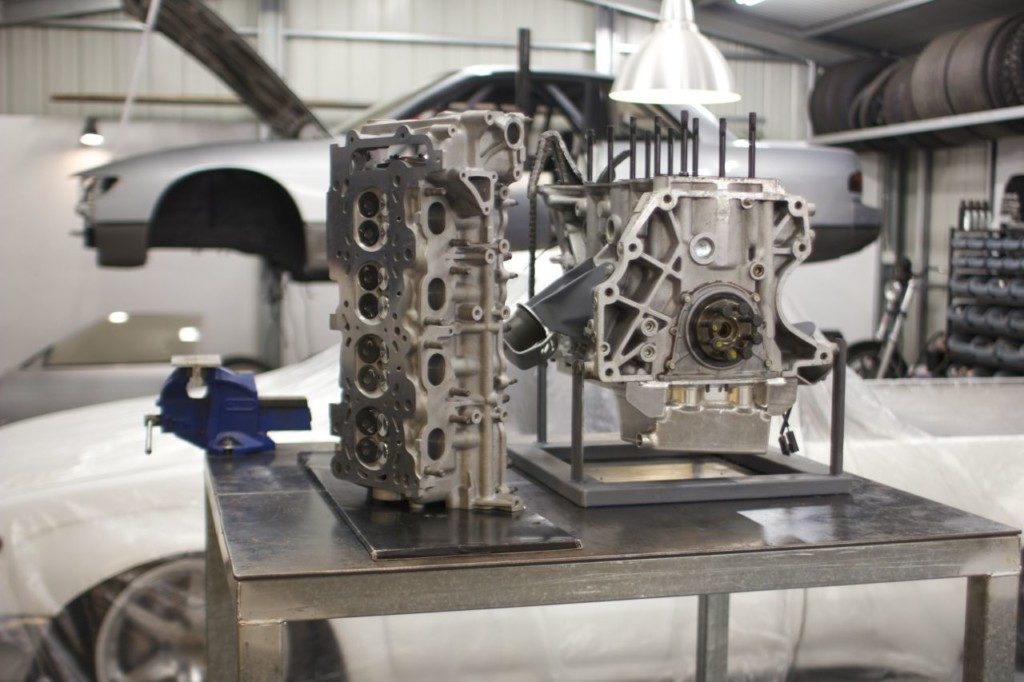

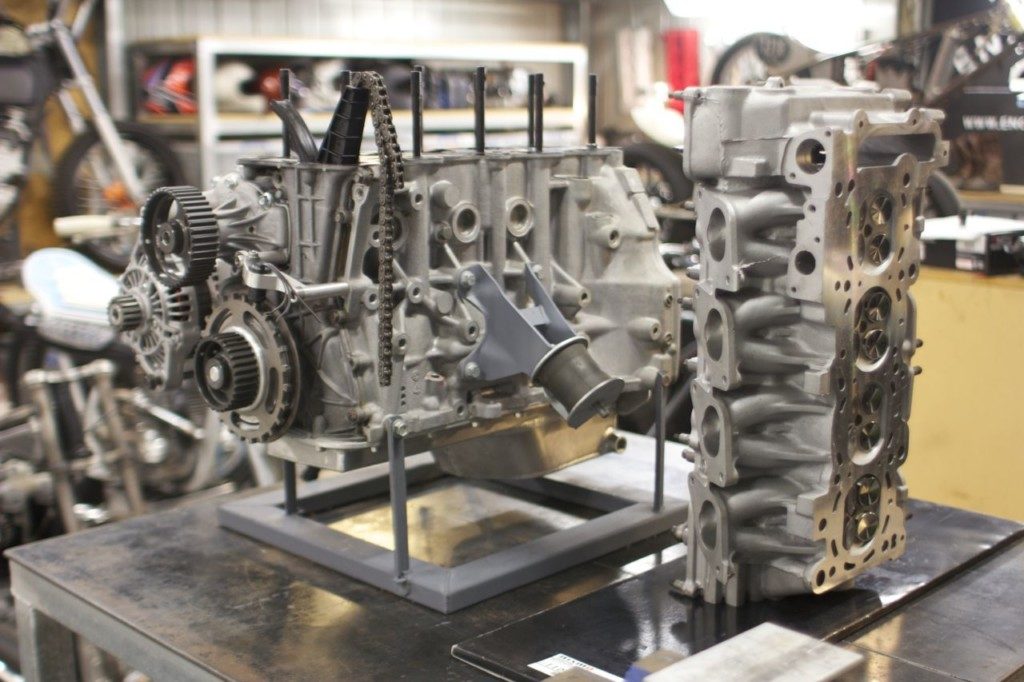

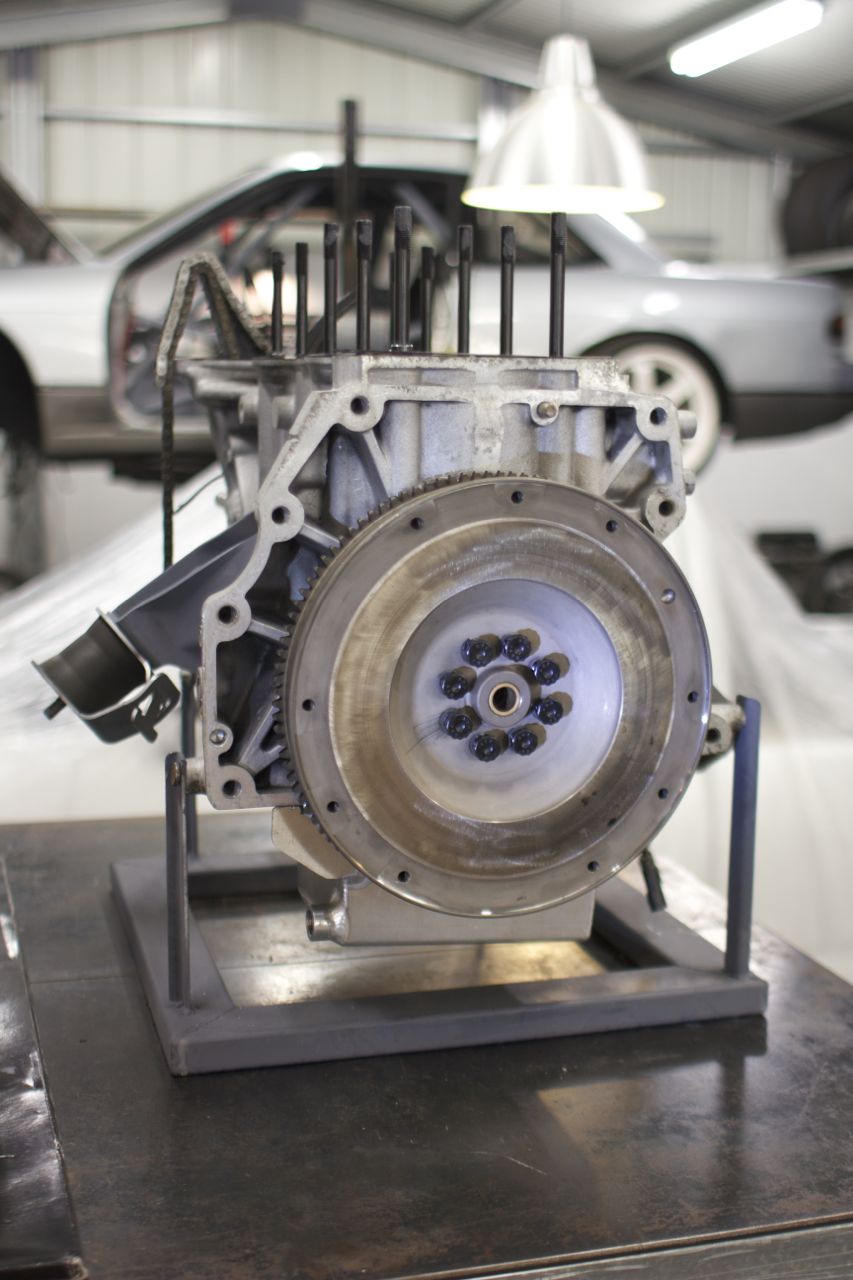

So now I had the stock engine on the bench and ready to pull down.

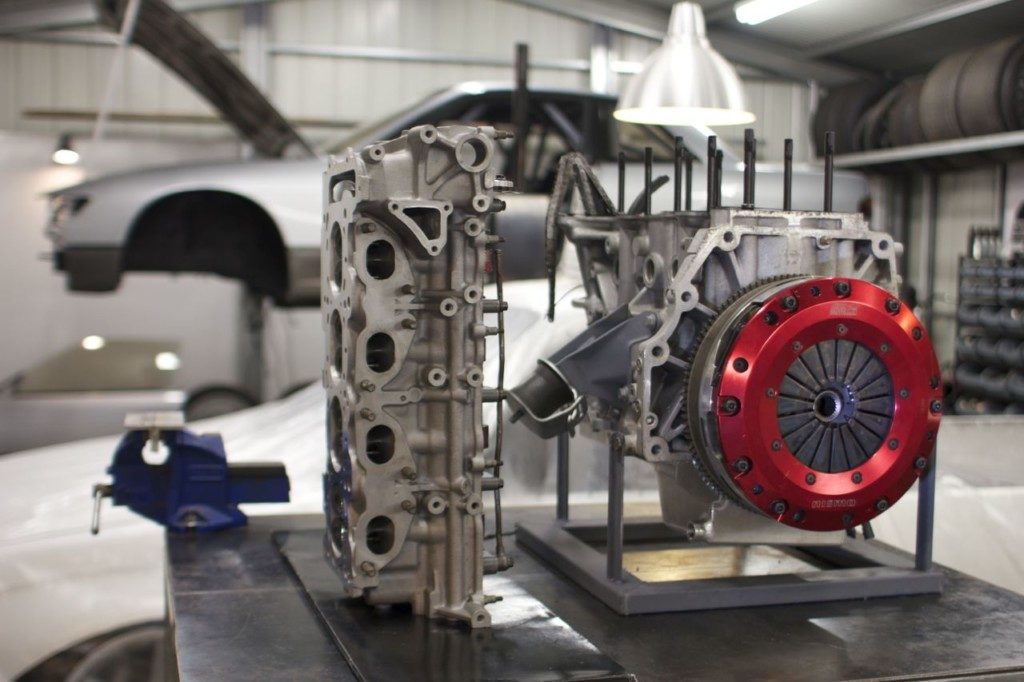

With all the ancilleries dummied in place I can finally finish everything off.

I made the engine cradle high enough so I can also pull the sump off.

With the crossmembers out I could also finish those off.

Its so easy for me to make everything for this car, the reason for this is paint! Paint hides a heap of imperfections and its something that has sped up the build process on this compared to the Hilux.

I dont have a heap of room when a project is in the build.

So once the motors finished it will all go back together.

I started with the removal of the stock head, all of that went into a box for spares later on down the track.

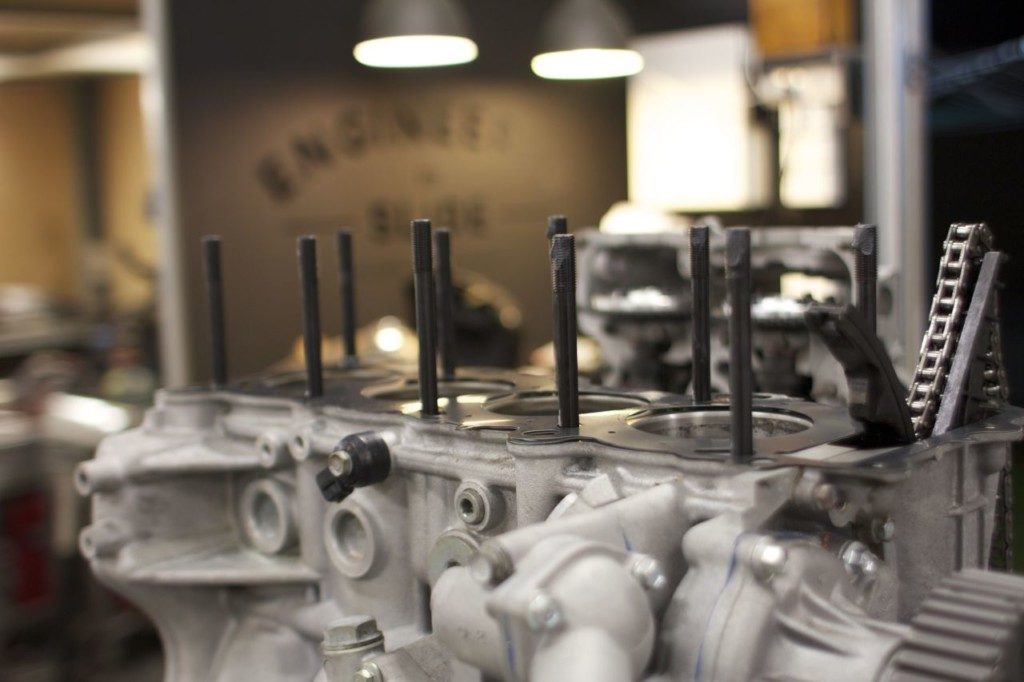

This is my ported and polished head with some fresh machine work, its equipped with Tomei solid lifters, new rockers, Tomei valve springs, Tomei Pro cams 270 degree and 12.5mm lift.

I grabbed some new hardware to screw everything together, the ARP headstuds clamp down a Nismo 0.5mm Headgasket.

Aswell as ARP flywheel bolts on the Nismo flywheel.

I am getting excited now.

With the head on and torqued down I can start to think about everything else.

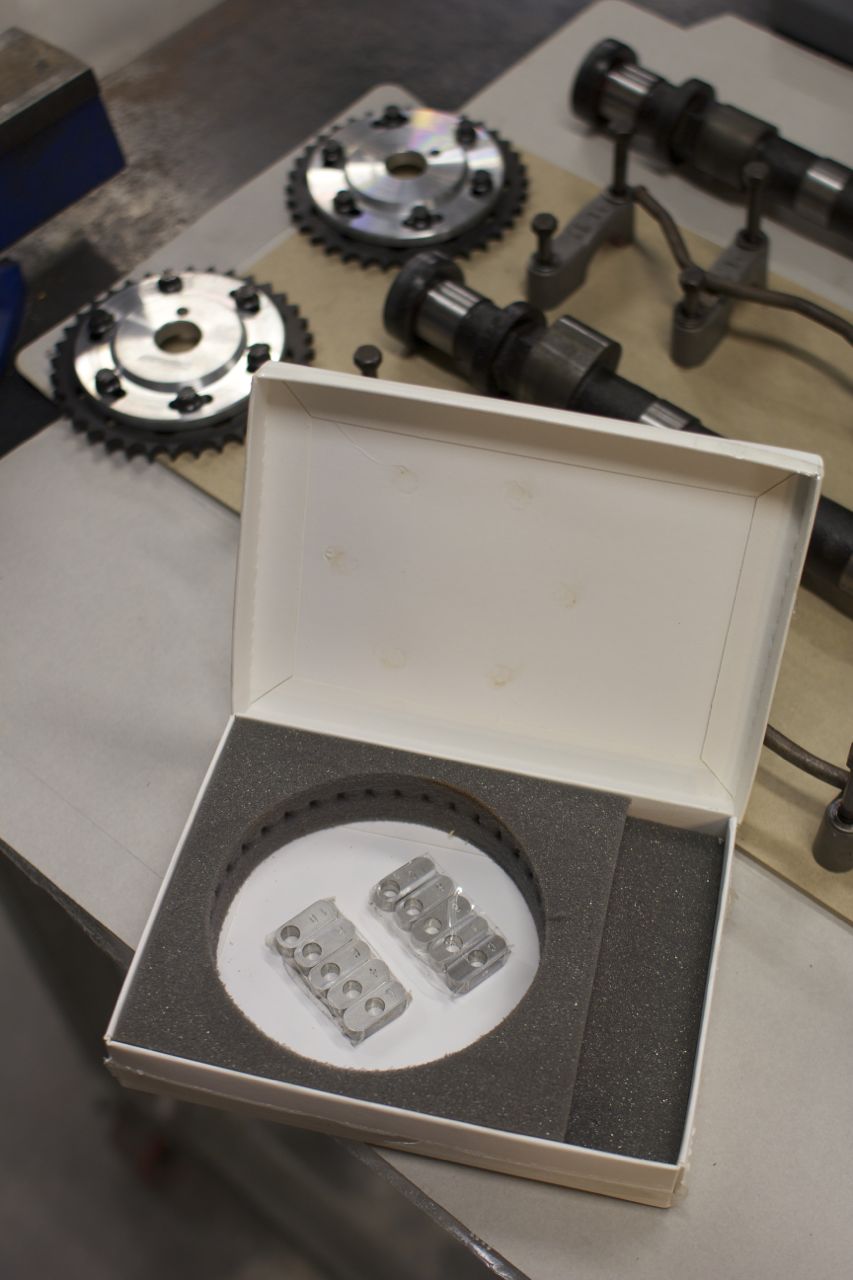

These Spec cam gears are a really nice setup.

They have foolproof adjustment.

By using these degree spacers.

A few weeks ago I sat down with a pen and a piece of paper and went through all of my plumbing needs, direct from Summit racing I was able to get everything I needed, I am super picky when it comes to fittings and I spent a lot of time selecting the right stuff for the Hilux build and was stoked at the outcome, so I went down the same path and selected just about everything I needed from Summit direct from Earls, its hard to find anyone that stocks as much as they do.

So this is where I am at, I hope to have it mostly finished towards the end of this year, not exactly to the level that I had once hoped, 450cc less but $10k ritcher for something in the future.