When you start building steel structures at home you can achieve most outcomes with fairly simple tools, a welder, angle grinder, drill and vice. The skills to use these tools vary and once you are competent and have a knowledge in how to use them the skys the limit, but there’s will always be one tool that is expensive to obtain and without it many jobs are considered impossible no matter what your skill level.

Having the ability to bend tube at home is the key to any chassis, rollcage, bracing and visually appealing steel structures. There are two components used to bend the steel or alloy tube and thats the bender and the dies.

The bender is a fairly simple unit, a steel outer frame that positions a bottle jack (atleast 3 tonne capacity) in the base and then a series of holes up the perimeter to position the dies.

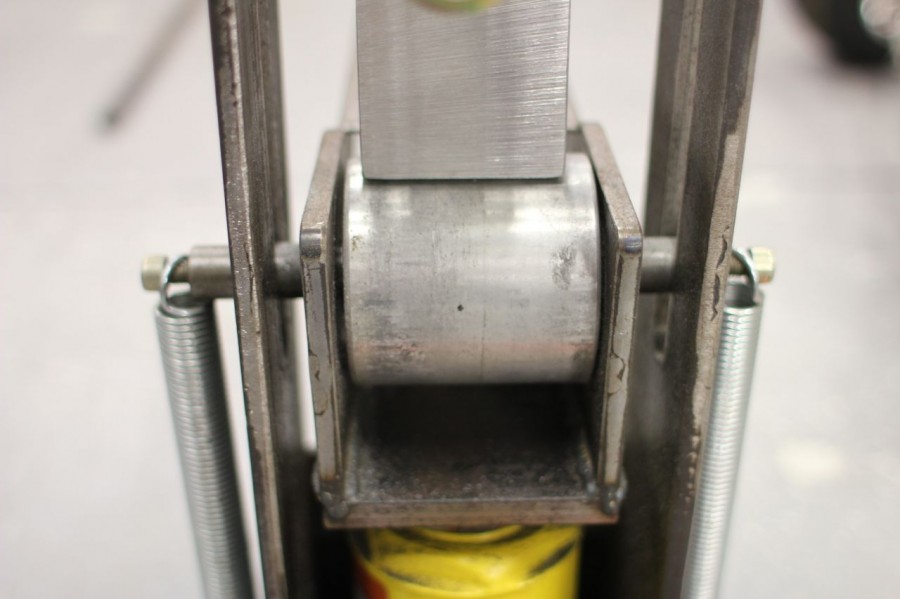

Above the bottle jack is a simple mount to position a large roller, behind the roller is a seat for the aluminium follower to sit on, the aluminium follower will run along the roller once the pressure is taken up on the die, the springs on the outer are there to return the bottle jack to its home position as fast as possible to save time.

The dies themselves are the expensive bit, you wont get much change out of $1200 by the time you choose three dies and get them delivered. I started off by buying a 1,3/4″ die and follower for the main hoop of a CAMS approved rollcage and a 1,1/2″ die and follower for the other tube. these are all I used for the Hilux project and now going on to the motorcycle build I just bought a 1″ die and follower and a 1,1/4″ die and follower to allow me to bend the smaller tube.

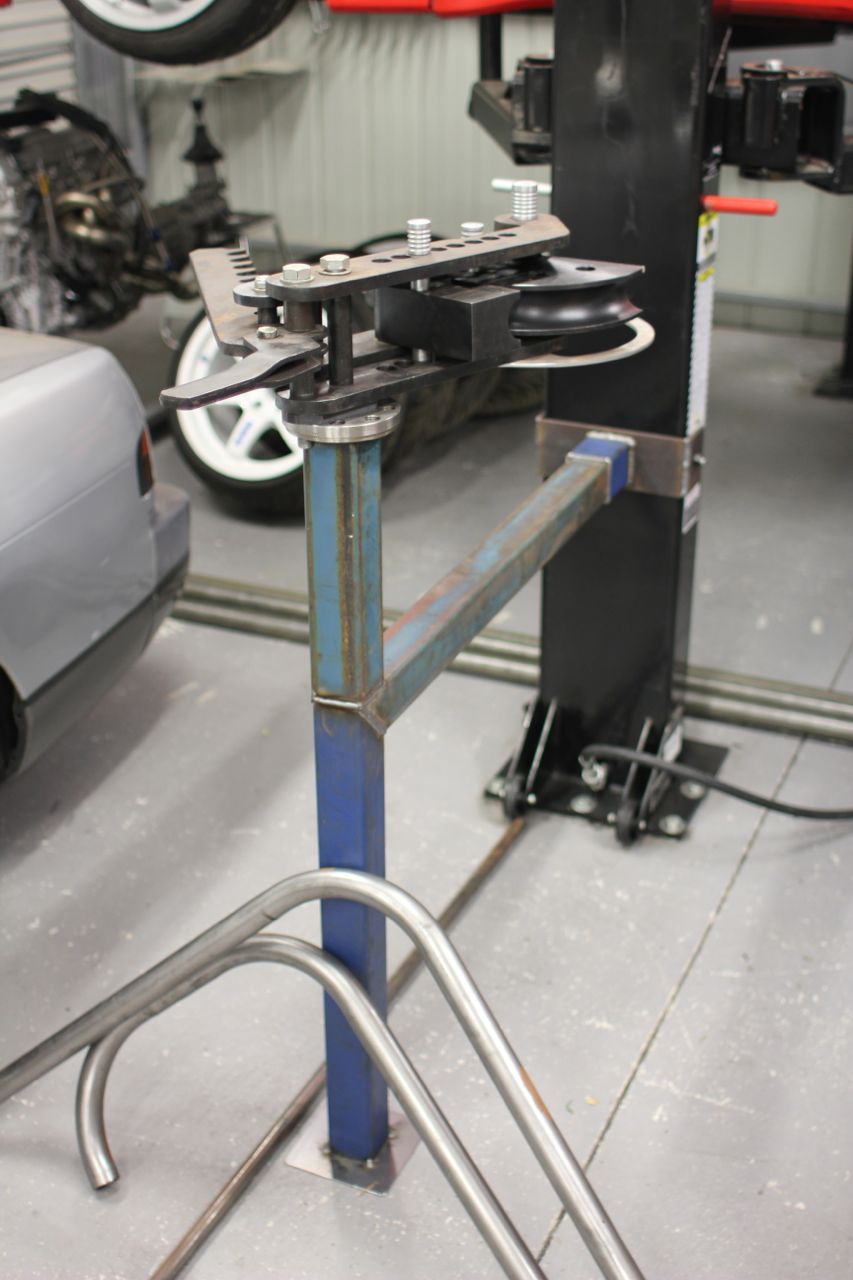

There are other types of benders on the market that I have tried, this is a horizontal ratchet style bender that I bought off a friend, I have since decided that this style of bender isn’t as good for my application and workshop space as it needs to be mounted to the floor or a beam and once its mounted cant be moved around, I dont have much space so this bender will be back on the market even before I have used it.

Looking back at my Hilux build I can attribute most of the chassis work to an angle grinder with both cut off disks and buffing disks and my bender. As I spend time in the garage bending up the tube for my PS13 build I am glad I have the bender in the garage and ready to go, it means I can get those ideas out of my head and get them tacked up.

When I get some time I want to make up a cutting list so that you can make a bender and roller frame by simply getting everything laser cut and then welded together. If your interested sign up to the mailing list and I will compile it and send it out.

Jon Hawkes

Utterly brilliant bit of kit. It’d be great to have one of my own to hand, thanks for making the designs available Nigel!

Chris Jones

Could you just post up a short video showing exactly how it works please Nigel? Does the pipe move through the bender by itself while your putting the pressure on it from the jack? And is it a maximum of 45° that you can ben? Sorry if these seem like simple questions but I haven’t used PR seen a bender like this before. 🙂

josh g

Cool little write up. Something my dad and i do to bend pipe is heat it up with a torch and wrap it around a large post at the shop. Works well for minor things. He even told me he seen a guy in the 80s build a whole drag car cage like that. Can’t wait the design to have a handy tool at the shop. Cant this be adapted to a full hydraulic press?

Stuart Buckett

i have a CAD file design for this type of bender if anyone wants it

Ryan Jackson

Can you please send me the cad file? [email protected]

Vince

Please send to [email protected]

Stuart Buckett

https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX

Charly

Yes please [email protected]

Jean-Francois Dubé

Yes ! Would like to have it !!

[email protected] !! Thanks !!

Kyle Campbell

Yes please! [email protected]

Ryan Smith

Yes please [email protected]

Frank

could I have it too ? ( [email protected] )

rargueta

thanks, here’s my e-mail [email protected]

Bauer

Could I also get it? [email protected]

blair mcintosh

if you dont mind ill take a copy.

[email protected]

supercboy

Could I also get it? [email protected]

Ben

Please send a copy my way as well.. [email protected]

StefanE

hey would be good if you could send me the files to cheers mate my email is [email protected]

Mike

I’ll take a copy please!

[email protected]

johan halvarsson

Yes stuart! Please hit me up dude! 🙂 [email protected]

Best regards from sweden 🙂

Blks Marek

Yes please!!!!!! [email protected]

Matthew Baldwin

Any chance you could send one to me too please stuart,

[email protected]

Thanks

Stuart Buckett

https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX Plans

Dave

Yes please! [email protected]

Matt Johnstone

Yes please! [email protected]

Łukasz Jankowski

Yes please! [email protected]

Ryan House

I would love to have it! [email protected]

Thanks!

Wan dalker

Yes please, [email protected].

Thank you

roger

Yes please!!! [email protected]

Matt Ambrose

Can I have a copy too please.

[email protected]

nrmmendes

If you won’t mind to send me I would apreciate, Thanks 🙂

[email protected]

Joel Matthew Pittman

Oh ill take one if you dont mind. [email protected]

Stuart Buckett

https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX

Stuart Buckett

If anyone gets a Quote on getting the steel cut can they let us know so people know what to expect Cheers 🙂

Neal

Hello,

Can you please send the CAF file to [email protected]

Many thanks!!

Neal

Jonathan Behn

[email protected] for a plan copy please. Signed up for Nigel’s too. Been waiting for this.

Stuart Buckett

https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX

Luke

Hi Stuart,

Can you plead send me the CAD file for this design too, it would be much appreciated.

[email protected]

Thanks

Luke

Stuart Buckett

there is a drop box link below

SMKFSH

I would love a copy or info on th specs for a roller please. Ive been fabricating for a company for 7yrs but have never gotten around to purchasing/building a tube bender. My emails [email protected]

Stuart Buckett

does anyone know of a file hosting site i could put it up on that everyone can download from? as there seems to be a few people who want it

Jacob Castricum

Grabcad.com

Stuart Buckett

ok i will posting a link shortly to a public drop box file 🙂

rusty

I would love a copy of the files …. Please !! [email protected] – cheers

J.r. Moore

just an idea for this post or another in the future. where you purchased the dies and parts to build your tube bender. i am sure a lot of people are interested in just trying to get into fabrication and have no idea where to start. I do so much reading before purchasing it would be great to have some ideas of how well products are made and how well the company treated the purchaser. great post by the way nigel 🙂

Stuart Buckett

https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX

theirs two designs in there take your pic depending on what jack/ram you want to use

roger

[email protected] please and thank you

Сергей Грачев

Hi, I have long been following the blog and I like this article is about benders. I will be grateful for the drawings to create it.

My mail: [email protected]

Mike Dias

Can I have a copy too please.

[email protected]

Stuart Buckett

DRAWINGS FOR BUILDING YOUR OWN https://www.dropbox.com/sh/rnx5d303jjl71to/lWwx_ii-hX

Guillaume Alix

Could I have it too [email protected] thanks!!!!