Well I was not happy with the old inlet, so I made another, take a look.

This was the old one, it was good but made working down near the alternator a real pain in the ass.

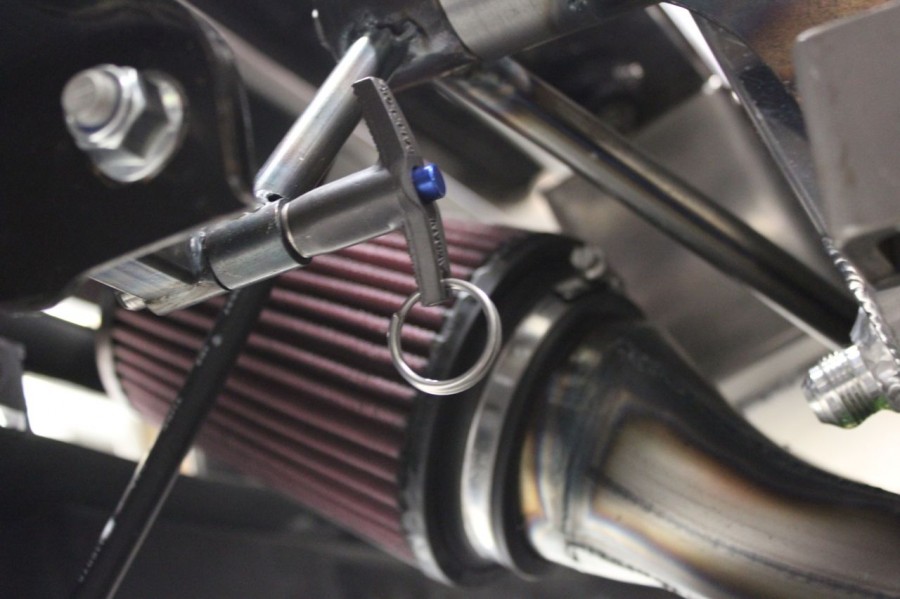

Using 0.8mm sheetmetal I fabbed up this new intake, it has a nice tab off the side and screws up into the radiator support with an M8 bolt. Whats it advantages? Cleaner air, easier to work on and much more user friendly.

It looks a bit menacing without the front end on.

But when the front end is all fitted it sits right at home in the bumper.

Theres more than enough clean air out here.

Rob Neeley

Does the cross sectional area remain the same throughout those bends? It’ll work just fine I’d imagine, your ‘tricky to work around’ idea seemed better.

You could remake that, the filter could sit wherever, but the big advantage would be a duct easily made the width of your radiator to take advantage of the positive pressure that ‘will/could’ exist there.

Sean Hurley

How will the flat section effect your flow rates? Looks messy

William Black

Looks really good man the only issue you might have is the turbo might suck that silicone bend in at high RPM and boost but should be sweet.

Sean Conlan

Just done a project for University on the flow of air through tubing and from the shape of the design there is going to be a significant drop on pressure as the pipe flattens out. the more surface area the worse the boundary layer is this slows the flow velocity. if the end was the same as the rest of the tube it would be better as there would be no pressure difference from except for where the pipe narrows before the turbo… Good thing to do would be to look into getting the inlet put through a CFD analysis software if you could….

Dennis Datu

With the lack of room I guess you did the routing as best you could. But considering the comments about pressure drop etc. an alternative is to use a short tube with a mushroom filter.