You may think that because the Hilux is running the build would be coming to an end….. Not so!

There are so many little jobs to still complete, one of them was mounting the front bumper.

This is the 4th generation bumper mount, like most things I have learnt what to do after completing what I have done, this means starting from scratch and skipping things up a level.

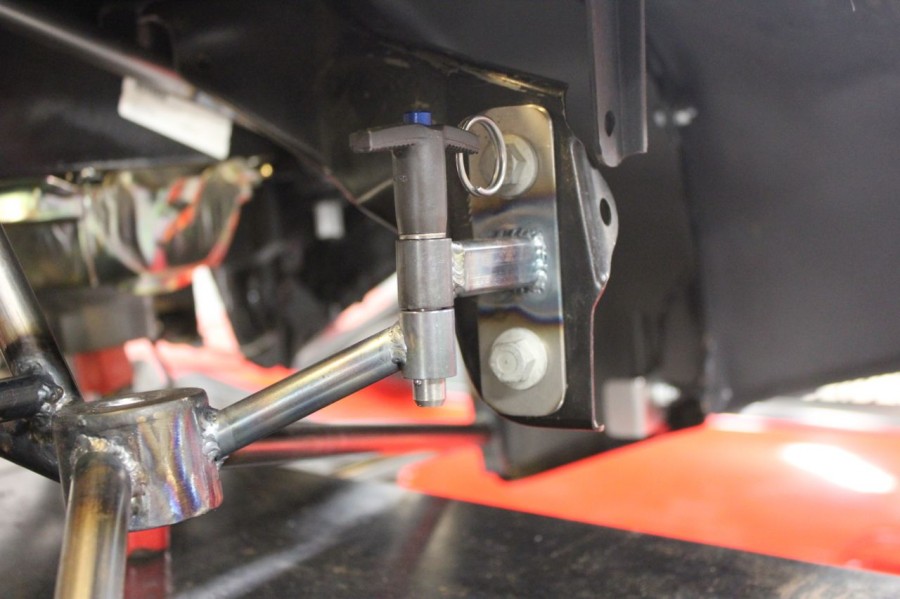

This time I wanted to use Ball-lok pins, these pins are commonly used on drag cars for wheelie bars, rear wings and anything else that needs removing or adjusting trackside.

It means I can remove the bumper with no tools and its a sturdy and strong fit up.

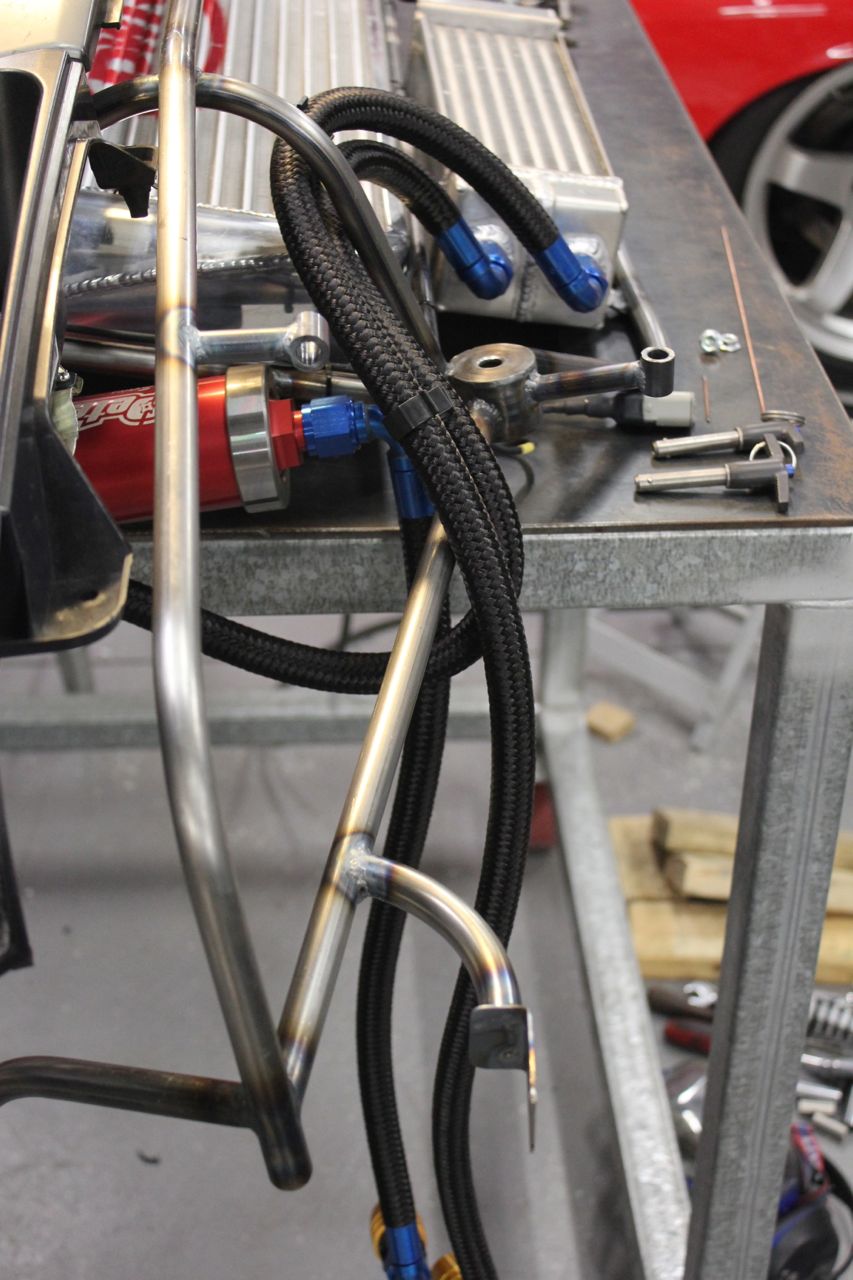

I love using tube to mount things, it is incredibly easy to use once you get some confidence with it, I use a lot of 16x1mm ERW Bright tube bent using a plumbers “pipe bender” (pipe is measured internally, tube is measured externally)

I simply use an angle grinder to notch and cut it, you could make some incredibly strong structures that are also very light, cheap and look amazing out of this stuff.

With the front bar mounted you can see the points in which it mounts. I wanted to secure it in two directions for a neat fitup.

This entire front end section is removed by only 4 bolts, Intercooler pipes are quick release, oil cooler hoses are quick release, its a pretty complex front end now.

I wouldnt mind getting the front bumper remade from FRP, I have a HOT ROAD vent I could fit in it aswell, adding some year 2000 style to it?

With the front structure off the chassis I will show you another thing I have been working on.

Oh but before I do these blanking plugs for the radiator inlet are a must if you have a thermostat, with the thermostat closed it still leaks a small amount of coolant and can take days to leak out, wanting to keep things clean its a good idea to blank it after the hose is removed.

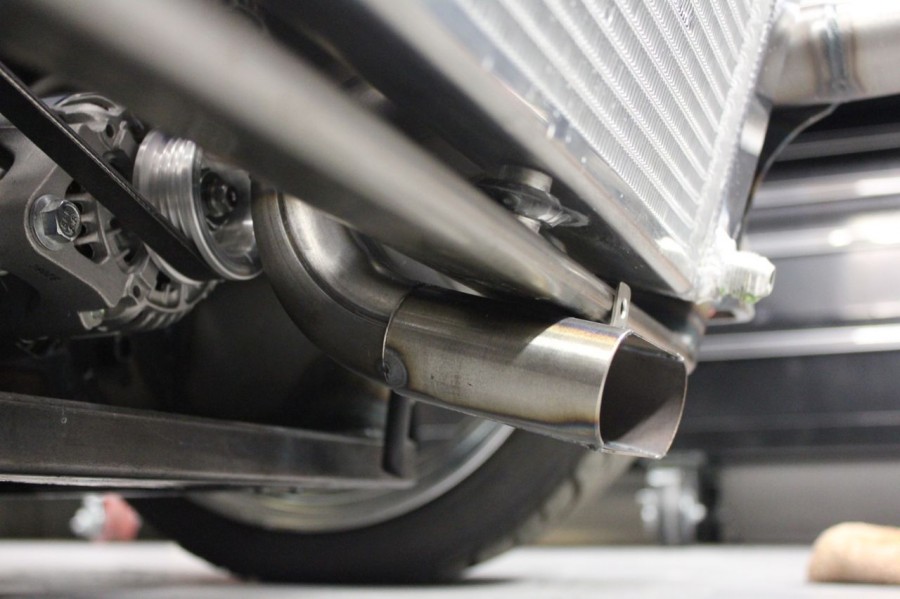

That thing I have been working on is the intake, its generation 4 now and uses a 3.5″ to 3″ 90 degree bend off the turbo, down to a 0.8mm sheetmetal 3″ to oval to 90 degree oval bend. I made this out of a 1.5″ bend that was leftover, I sliced it in half, bent some 0.8mm panel steel and tigged it all together. Now i have to make it come back out to 3″ round and kick it on an angle for a normal pod filter to attach.

I carried the front end over from the bench and fitted it up onto the hilux, the top rose joint mounts have a pin that retains them so I dont need screws to have it hanging, all these little things make my life easier and make it a one man job, very important when your a 1 man band.

You can see where that air filter oval is poking out, I will make a sheetmetal tab to mount ot to the tube and then continue the sheetmetal work to finish it off tonight.

Its another step closer, I have to wait for my widened front guards that I made to be moulded and a panel made from FRP before I go much further with the front end, my bonnet is also being made out of a single layer FRP mould, then its time to mount some bonnet pins, stick the front windscreen in and the body will be done.

I have been trying to plan the first drive lately aswell, my friend is filming this for me and we want to do it properly with a proper production for you guys at home, for this we need 4 hours at a track in private and so far the cheapest hire is $4000, I simply cant afford that and I am extremely unhappy about having to wait. I am going to try and work every avenue I can before I give up on the idea. The longer I wait the further the final finished date will be, the powdercoater is ready to go as soon as the first drive is done so the plan goes like this.

Drive it

Pull it down to a chassis

Send all hot parts to Hi Octane Coatings

Send chassis, front and rear structure to powdercoaters for clear podercoating

Paint cabin, guards, bonnet, refit windcreens and finish bodywork.

Refit everything, loctite and tighten to final specs.

Debut it at an event in 2013…………………….

Maybe next year i will have a rest!

Carl Jarrett

Love watching your build progress. So close to a completely custom car, just a few body panels and headlights, nuts. Any ideas on a project after this one is done?

Dennis Datu

Loving the details man… just wondering why you prefer mounting the inlet so low. Wouldn’t that be prone to sucking air full of dust.

Carlos Alonso

His next project should be taking his wife on a nice vacation and getting a full nights rest.