Well this is something i have wanted to do for a long time, i never fully wrapped my head around it until Andre from STM explained how a crank trigger works, his HP Academy cirtainly taught me a thing or two.

My aim was to ditch the factory crank Angle Sensor, why? Well its not that they dont work, its that they can be unreliable at high rpm giving slightly false signals, the factory CAS has 360 slots that are picked up from an optical sensor, i guess its because i enjoy making things so the prospect of running a entirely new reference and signal setup seemed good to me.

The sensor itself is is a Honeywell GT101 magnetic micro switch thats sometimes called a hall effect sensor, they are a really cheap and reliable way of getting a signal from the crank and the cam. The biggest bonus i see with a setup like this is reliability and replaceability, i mean its pretty easy to swap out a sensor at the racetrack if anything ever goes wrong. The sensor is also reading exactly what the crank is doing, its not effected by anything that happens from the crank to the chain to the cam.

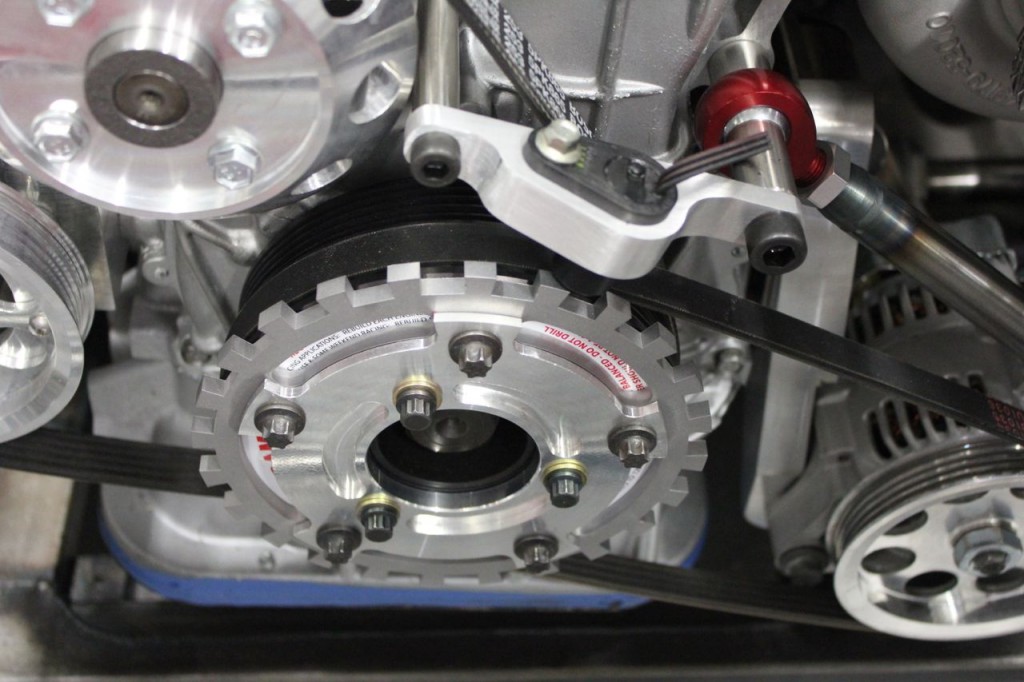

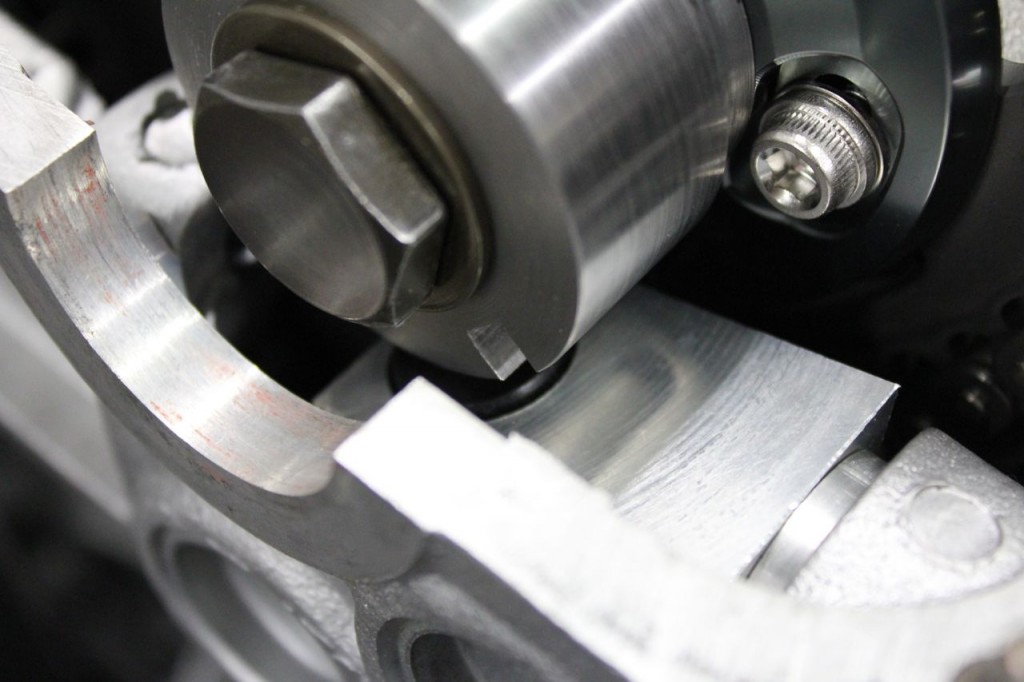

The wheel itself is something i made from scratch, the Motec PDF on the GT101 sensor explained that i needed a wheel that was atleast 6mm thick and 24 tooth at atleast 6mm wide and a gap of atleast 10mm. I made mine 6mm wide 8mm long and a gap of 12mm, its all bolted to an ATI balancer which is a very nice product and im super happy with how it turned out.

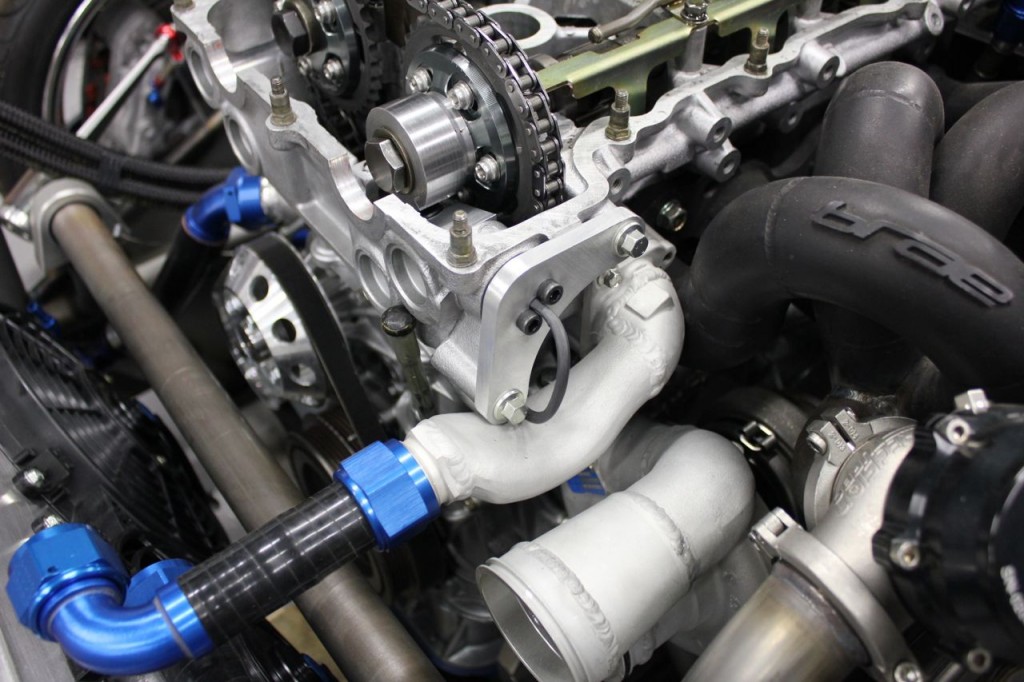

The cam sync uses the same GT101 sensor and uses a mount myself and Martyn designed. It requires one adjustable slot that allows the synchronisation of the orientation of the engine, this way the cam and the crank are signalling the ECU

I have since reworked this a little and am keen to offer it to the public after its tested, so Andre and Ben are set to arrive in just weeks and that means this engine will be running and all the questions will be answered as to how well everything works.

Sean Conlan

really likin the sensor right ups mate… keep up the good work…

Mattias Sandgren

Just a friendly tip: The crank sensor should really be clamped (around it, or on top) in place, unless it’s a press fit in that hole. I usually cut off the whole tab as it’s quite useless on a running engine as the sensor tends to vibrate and in some cases has been known to either snap off or move too much and collide with the trigger wheel.