There has been so many times in this project that forward thinking has lead to brain boiling headaches, one of those headaches began when i started shopping for fittings. I wanted to be able to get everything from one company and it all had to be the right fit for the project. Having used Earls fittings in the past i was always happy with their product, they have a massive selection to fit just about every situation.

I have a challenge for you…… head to Summit or Jegs or any performance supplier, look through the range of fittings available and “add to cart” everything for one system, be it fuel, or brake, you will see the headache i gave myself. Then look at the final figure and imagine trying to fit out an entire ground up build using nothing but matching fittings from one supplier.

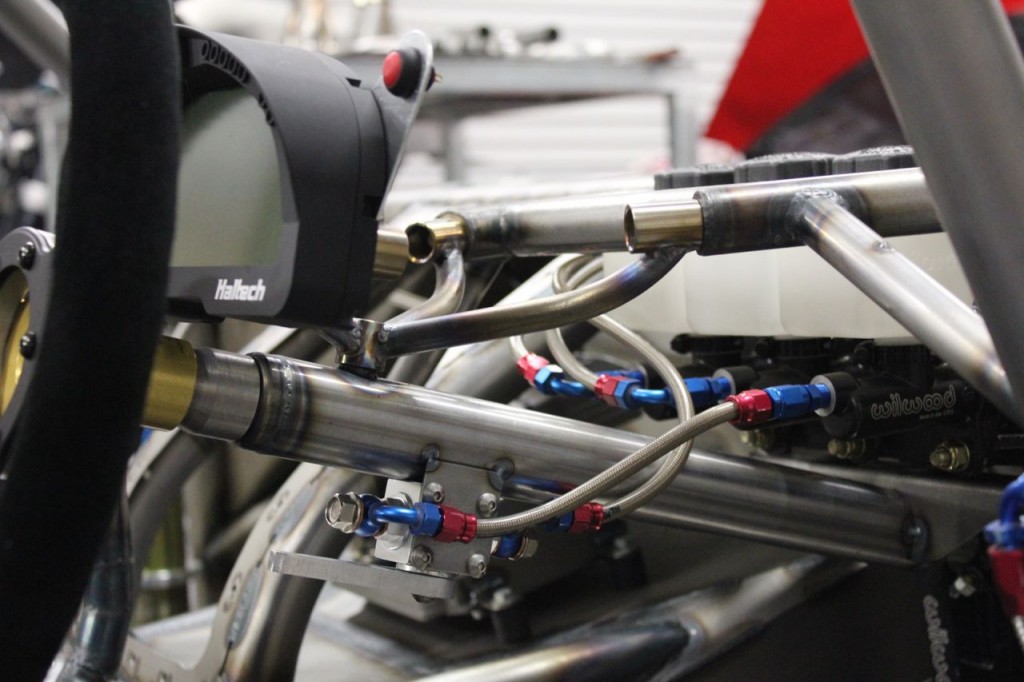

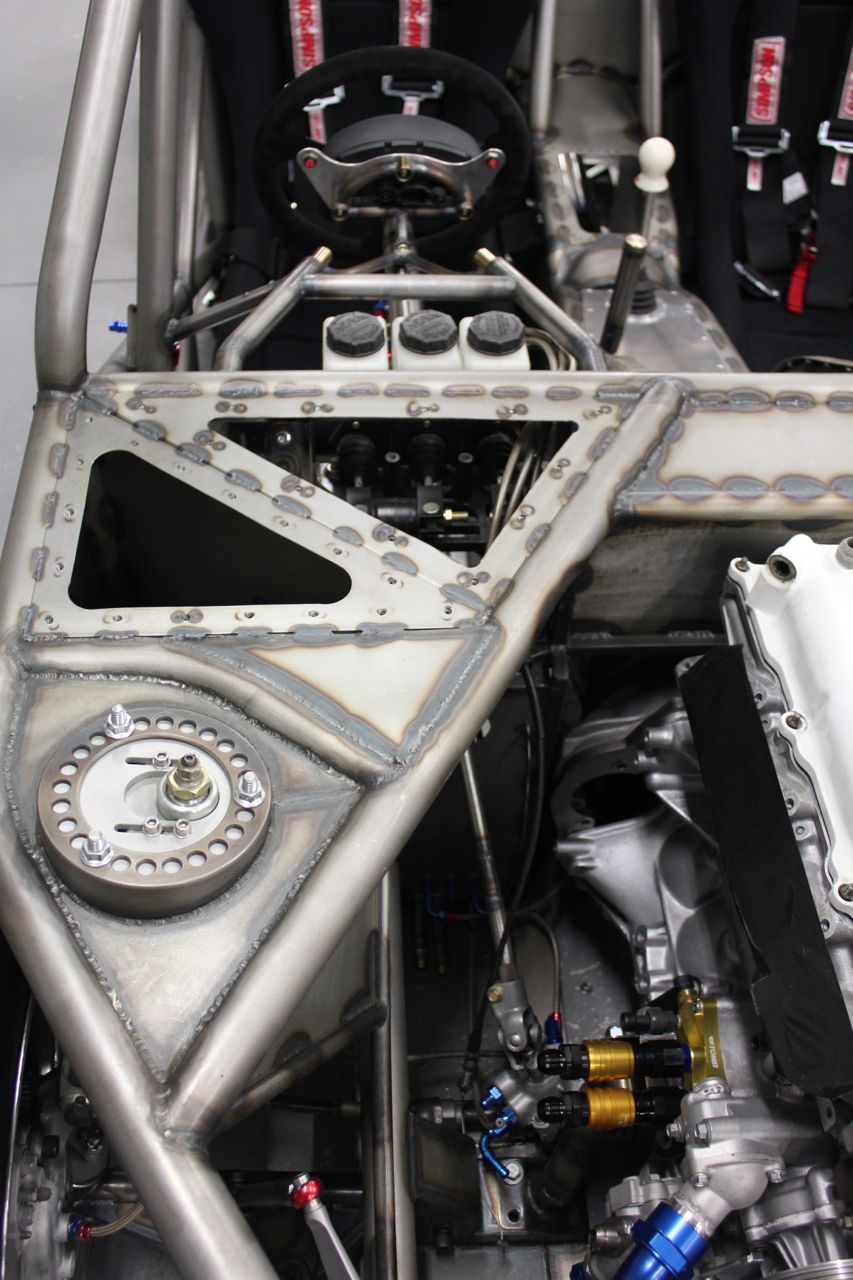

If thats not difficult enough then i was redoing everything, i mean take the Power Steering system for example, you have adapters needed to turn M16x1.5 M14x1.5 into 6AN and 8AN, M12x1 into 4AN and thats pretty simple compared to the braking system. The braking system needed to be 3AN so i had to deal with American pedal set being 1/8NPT Japanese calipers being M10x1 European hand brake master being all types of weird fittings.

Its good to see my pair of rear spare Driftmasters sitting here after their big trip from Japan, i never intended to run these wheels on this project but i just cant seem to accept any other look. I grew up on being obsessed with early 2000 japanese drifting, at this point in time the Driftmaster was the wheel to have, being a 2002 model Hilux body its a perfect era match and something that suits it down to the ground. I mean how many Hiluxs have you seen with these wheels on?

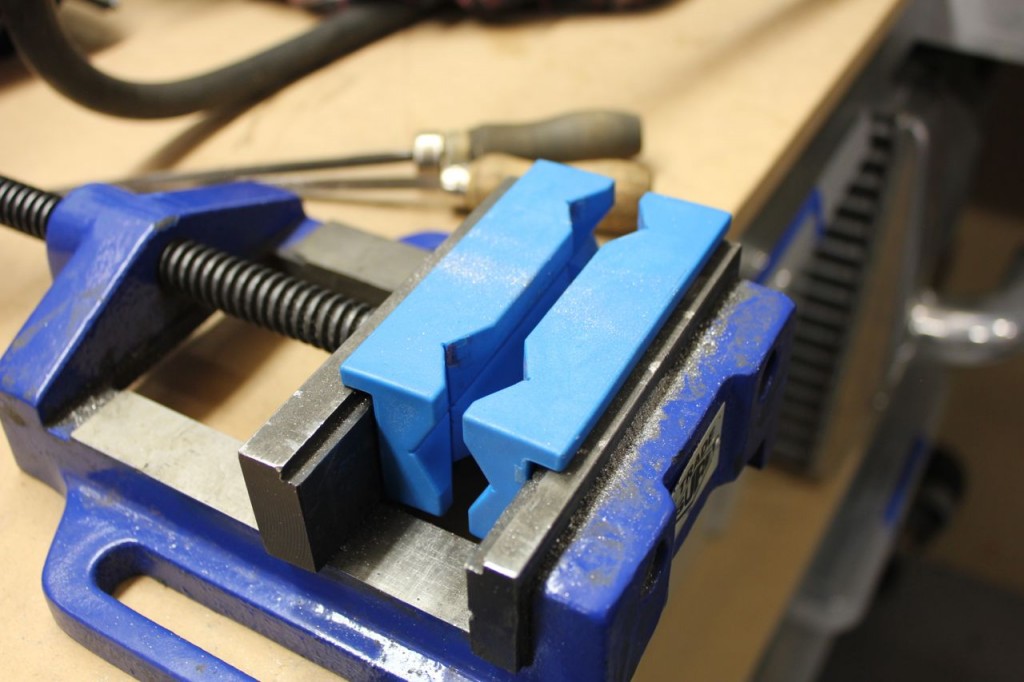

Theres been plenty of long nights sitting at the bench listening to the radio and just screwing fittings together, honestly these plastic vice jaws are worth their weight in gold, they allow you to tighten them up with ought bruising the alloy, another must have is the alloy spanners used for AN fittings, again every tool that makes your job easier is a tool worth having. From here on its all Earls Pro Lite 350 hose and Auto Mate fittings with crimp on ends. The Auto Mate ends are all blue and the hose is black so im happy to say thats the end of any red anodizing on this project. I am also toying with the idea of buying a crimper and using my hoists oil pump to pressurize it, otherwise i will make up all my lines and send them away to be crimped, so stoked i wont be screwing fittings together for the next month!

Ben Walker

what is that shut off valve under the steering column? like a line locker? where did you get it and what brand is it?