Sorry for the delay in posting this but its been a pretty busy week. With round 2 of the Victorian Drift Championship on saturday i spent a few nights prepping the 180SX, then sunday was spent cleaning and planning all those fix up jobs for the next event at WTAC, enough about that on to this!

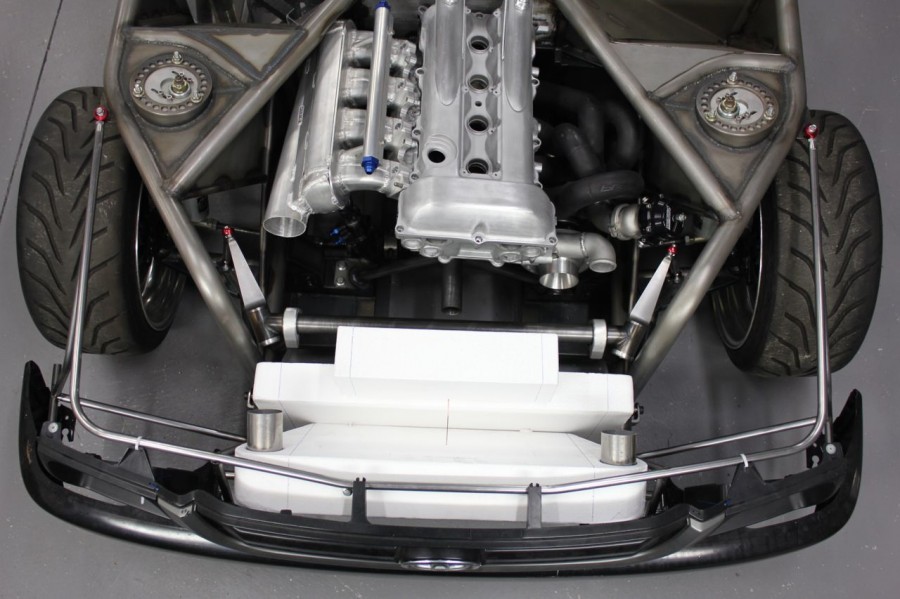

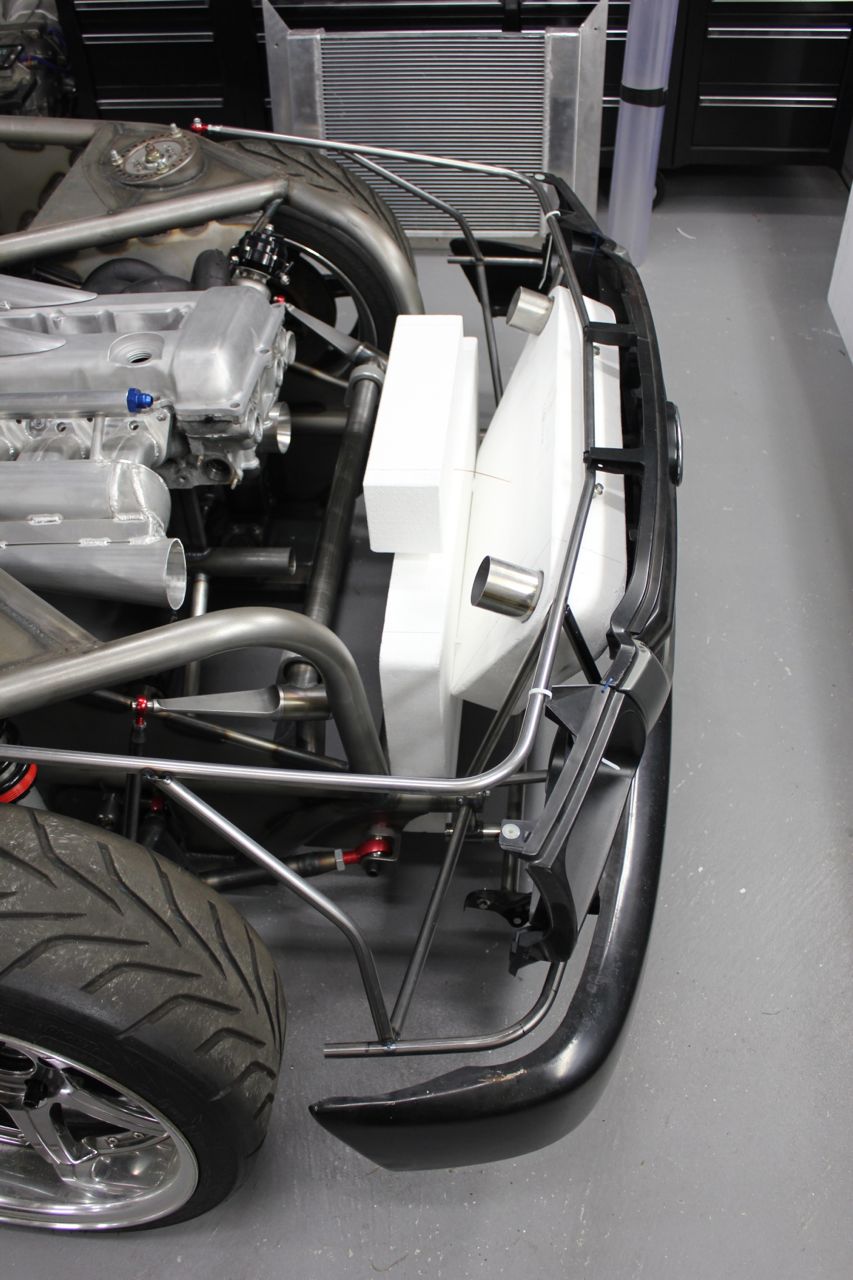

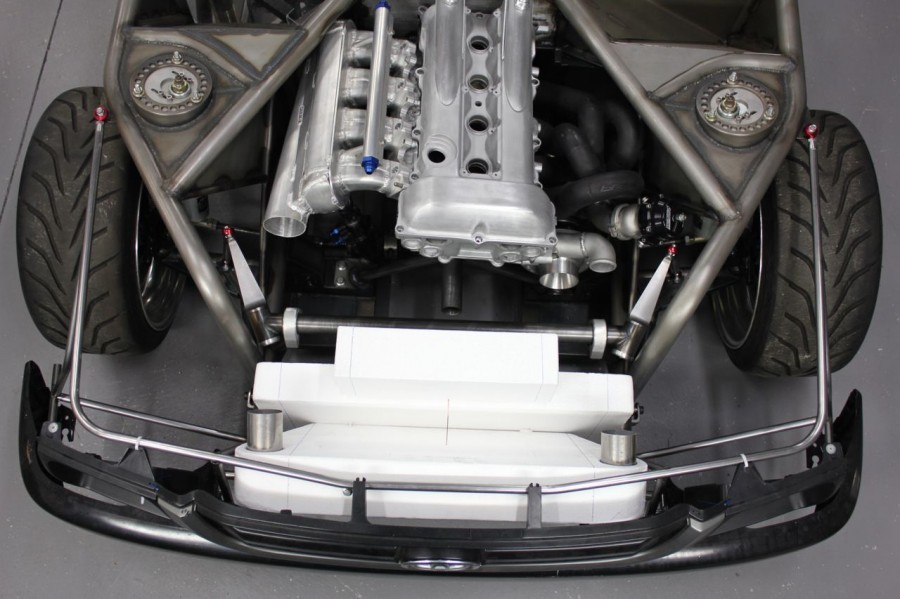

Last week i spent a lot of time building a new front clip on section out of 16×1.2mm tube, this means the old one gets thrown in the bin (which is becoming all to familiar now) but I’m much happier with how this one fits.

All the front end panels will be mounted to this frame and the front bumper just slides in and has a quick release mechanism to make tool free removal.

So now i had everything sitting where it should it was time to rethink this whole cooling situation, using foam i cut out all three coolers to the dimensions i needed and was able to sit back and have a good think about things. You may be thinking “i thought the rad was in the back?” well it was and now its not.

I was never super happy about the whole rad in the back thing, i mean yes it would be nice to move some weight rearward, but i honestly don’t think it would be worth all the trouble…. At the end of the day if it needs more weight in the back i will just strap ballast to the chassis down low, i think the radiator exposed in the tub would be a lot of trouble down the track and thats not what i want.

The radiator measure 700x400x65mm the intercooler core is 500x300x90mm and the oil cooler (which i have ordered from the US and is on its way part number Allstar ALL30146 ) is around 400x120x120mm. I will be doing some pretty nice ducting and also a decent vent in the bonnet to get the hot air out of the intercooler and oil cooler. The radiator gets 200x700mm of fresh air so there won’t be a problem there.

With the motor sitting so low i was able to make some pretty beefy breathers on the rocker cover, essentially the same design as my 180SX it will work really well and also look a little neater/ different than usual. I also cut off everything that wasn’t needed off the rocker cover and welded everything up again, a lot of sanding and cleaning was involved in this too, yes thats not pain its raw alloy!

I just have to gain some more confidence with the TIG before i tackle the welds.

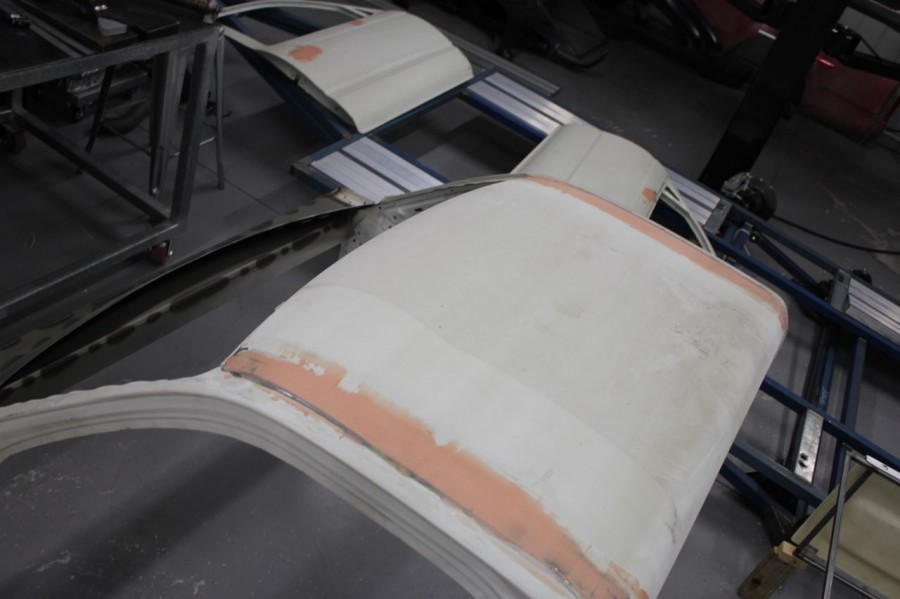

Im on a personal deadline at the moment, i want the entire body all finished and in undercoat before the start of next month, i welded up all the holes in the doors, the roof gutters and anything else i could find, my mate Greg came over and applied some filler to save me the painful job!

I have spent a lot of hours on the doors and have got them to the stage where I’m pretty happy with the fit, ease of removability (they simply lift off) and am now designing a neat door lever/ opener, this is a trick from the drag racers, a small hole in the lexen window is all you need to operate the handle that will open the door from the inside or outside. Some drilled alloy will look a treat once all finished.

I also grabbed 10 of these Avibank Ball Lock pins from a nascar team in the USA, they are a neat little alloy handled item that will be used to remove the entire rear subframe and paneling, i really want the whole lot to be able to be removed without any tools.

So thats pretty much it for this post, i have a heap of work to do this week, now the bodies off i can finish all the welding i had trouble getting to before and then its time for a full tare down, cleanup, and then refit everything, it will be a full car soon i promise!

Jake W

So inspirational mate, can’t wait to see it done!

William Black

Its looking great Nigel and its really starting to take shape! Wont be long!

Russell

Insane man you a.d her have come a long way!

Tonyk

Looking sick Nigel! More and more like a pro race car. Good on ya!

Thorson

This car needs to run a back-up body style if you can remove the panels with such ease!

I’m thinking some kind of Mad Max post-apocalyptic sliding machine.

Matt

Dear lord! This thing has come such a long way, you’re dedication and craftsmanship is truly an inspiration. Can’t wait till I can attempt to make a project half as rad as this one.

Scott W

Looks amazing!

Brian

Mate, your a magician!!!!!

Steve Kae

she’s getting there mate 😀

Kamikaze BottleRockets

Awesome progress! Glad to see the radiator up front, lots of cars in the US are using rear rads and it seems pointless. If it’s that important, run a Porsche, problem solved haha!

Can’t wait to see you destroy some tires.

Jon

I don’t know how you sleep at night. Its so amazingly beautiful I would just stand there all night till my eyes dried up.

Over here in south Florida the mud trucks run the radiator in the back up by the cab all the air is getting pulled through from a big fan. Its really similar to off road race trucks.

Alex

Hey Nigel looks so good bro major inspiration. Are you gonna be taking it to wtac at eastern creek?

anthony

Just curious nigel, you no doubt would of thought about it but radiator on the bottom on the angle tilting backwrds and cooler above on the same angle obviously gap between them (smaller piping to plenum and turbo) oil cooler still up top or to one side behind headlight with a nice cover with a vent to it??

Looking forward to next write up..

Sammy

Have you thought about putting rad up front and a v-mount intercooler. Turbo piping would be as short as possible and with decent ducting and a vent in the bonnet it would work beatifully

Tristan Deall

Truly amazing work Nigel I can’t stress that enough, I know some people running tray mounted radiators in gq/GU patrols used for comps and they say coolings no longer an issue (bitch to set up properly though), makes sence to keep it simple though