You may have noticed that lately i mostly do a weekly update on the hilux build, i don’t really plan it this way it just seems to happen. All week i rush around and do as much as i can in the little amount of time i have, i never get sick of working on it and every little job is a personal challenge to push my knowledge and craftsmanship to the next level.

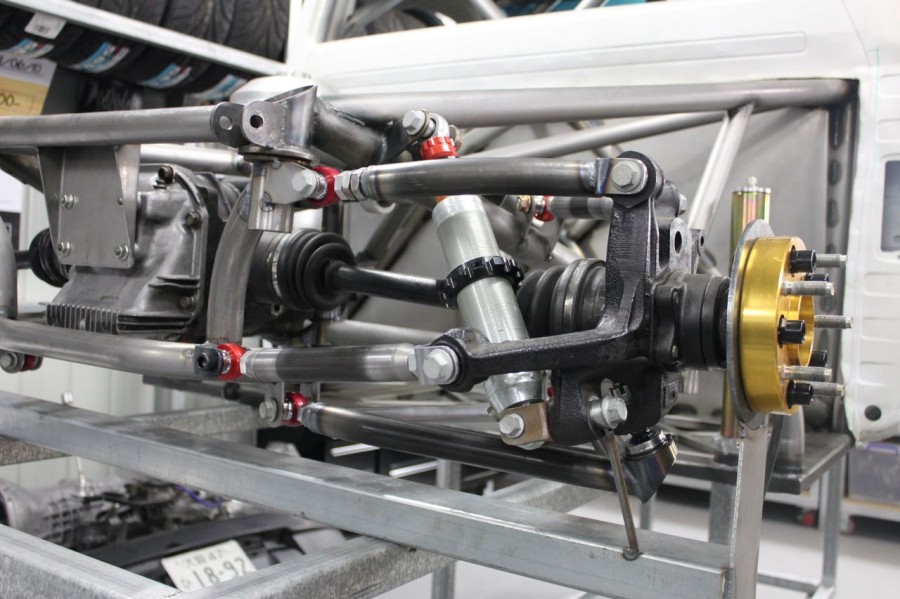

So this week i had few things i wanted to focus on, the first was to draw up some suspension clevises to produce my own suspension arms. These clevises mount to the factory knuckle and have a 5/8 UNF RH thread, all machined out of solid K1045 steel for the lightest and strongest arms. My local engineering firm knocked up 10 of them for me, these are something i might market and stock in the future, ill definitely never have to buy an overpriced crappy quality suspension arm again.

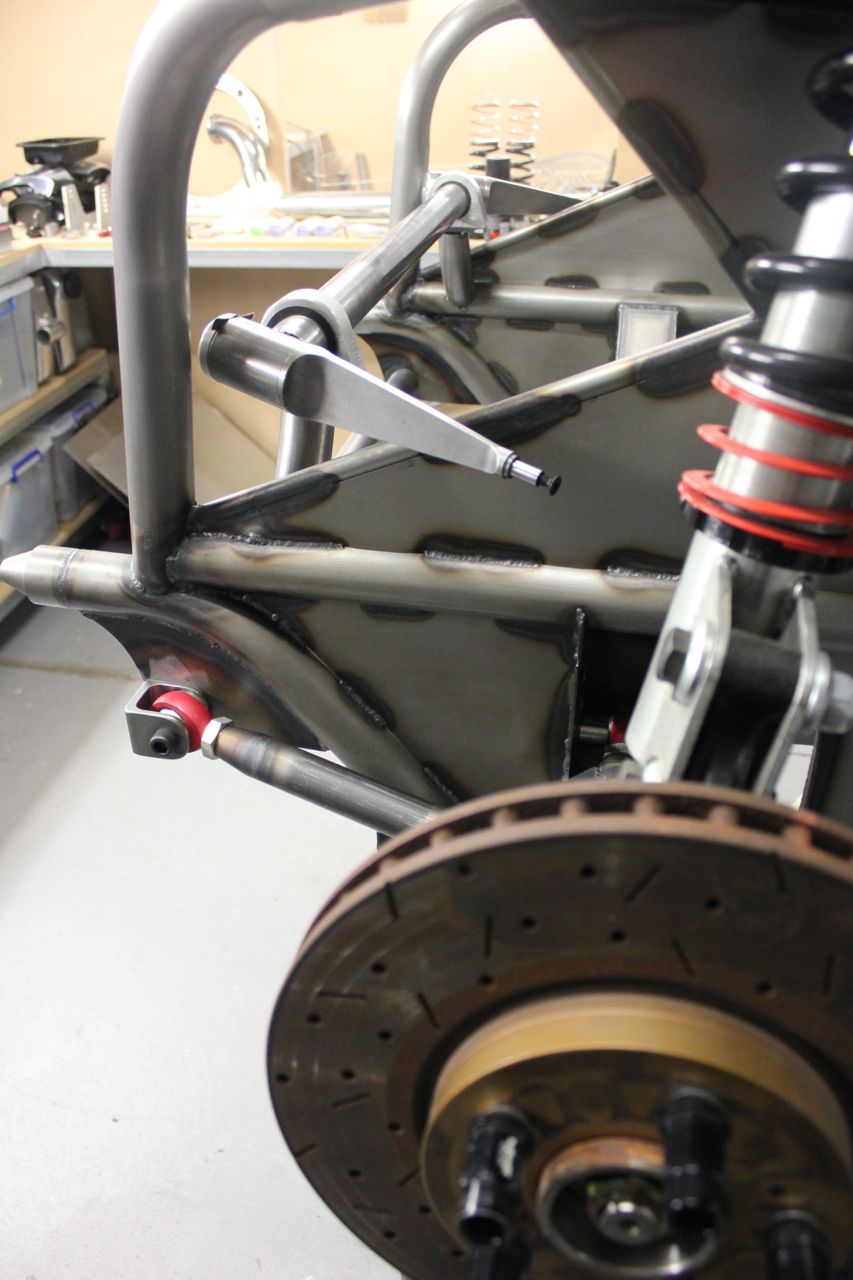

I finished the welding on the lower arms and still need to add a provision for the swaybar joint to mount to it but more on that later, its starting to look like a complete rear end with just a few welds to go before it will hold its own weight.

I have mounted my rear swaybar and tacked on the ends, i can’t wait to try these adjustable blades out.

Speaking of swaybars, i also mounted my front swaybar, i won’t be 100% sure on this location until the motor returns so i won’t fully weld it on till the next test fit of the motor.

I also finished of the welding on my front lower arms, i decided to gusset these up to make them super strong, I’ve learnt a lot about making arms lately and can’t wait to do it all over again on another project, theres just something about suspension arms that I’m in love with.

I always look forward to a TIG session like this, doing TIG work on a bench is so much more fun than twisting your body through some bars to get the right angle, i always clean my steel bench down, have a glass of water, relax then start welding. Believe me you can tell a relaxed weld from a rushed one.

A quick snap of my tube notcher on the floor of the “mess room” this is how much steel covers the floor and benches in only a couple of nights work, time for another clean up.

tom

awesome work, welds are looking dialled!

p dub

those arms and sway bars look awesome man… will be interesting to see how much difference altering the sway bars on the fly makes

Finlay

I take it the blades on the sway bars are so you can adjust the flex, that’s awesome, by the way.

Here’s my little truck – VW T25 1990, with subaru EJ20 turbo power, making 250bhp at the moment – looking for 280-290

http://a3.sphotos.ak.fbcdn.net/hphotos-ak-ash4/294969_10151287232977119_2056415854_n.jpg

Mitchell rowe

Wow nige, The craftsmanship in those arms and components are phenomenal.. an absolute credit to your hard work

Marshall Jung

Any consideration into making the suspension arms the “weak link” in the system? Inevitably an incident will occur and I think it is much preferable to bend up an arm instead of tweaking the chassis and the arm.

Nice work BTW.

Jase

Looking good Nigel.. your welding has improved quite a bit.

New front LCA looks much stronger than your first design..

I know its only taked on currently, but are you planning to add a vertical gusset to the shaft bearings on your rear sway bar.?

Nigel

Thanks mate, yes i am planning to beef them up a little, its a putty my welding is finally getting better and the projects almost done, time for another one 🙂

M

Mate, wish I can weld as good as you! DX

Joel

my 1st post here, been following your work for a while, wish i had the time to build all the ideas in my head.

anyway – im assuming the castor rods in “max castor” is enough to give you the castor you actually need?

i mean it probably is, just something i noticed

Also were the clevis’s CNC billet?

Nigel

with them adjusted the way they are i have way too much caster, they will be backed off and then readjusted on the ground. The clevises are just hand milled, not CNC milled, but yes they did start as billet material

Dennis Datu

same concern about the clevices… i hope there’s enough material there to prevent it from shearing.