Oh man, its been a big week! Late nights and early mornings seem to just be the normal for me now, its another full time job on top of my other full time job, heres the run down on whats been going on this week!

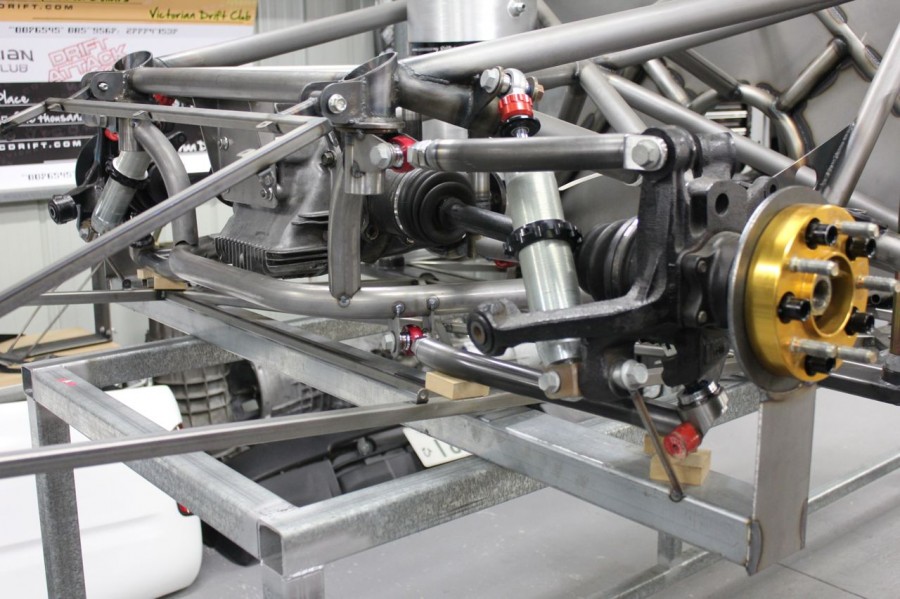

I started with the front end, i didn’t like a heap of things up front so i started from scratch! The arms are now 1.5 inch chromoly with a 1.8mm wall and then 1.25 inch caster rods that sit inboard and then mount to the chassis with a neat double shear bracket.

The rod ends are .75 inch and at the moment everything is tacked up and ill spend a night welding them next week.

Ive also done the rear lower control arms out of 1.25 inch chromoly, again everything is tacked together and i have to go over the measurements before the final welding.

With the lower control arms done i moved onto the camber arms, i had some old broken bent arms (thanks Ritchie) and used the big adjuster and just redrilled and tapped it for the 5/8 rod ends that are used throughout the entire rear end.

I drew up some unique arm ends to bolt to the upright, these will be CNC machined from billet K1045 steel and incorporate a 5/8 thread that will screw onto the upright, these will form the traction rods and toe rods so as soon as those are done this will roll once again! As with every week i learn so much about everything that I’m doing and that will continue throughout the build. Things are getting exciting now!

Trent

AWESOME

Seth

All the work you do is definitely an inspiration to me to keep building custom stuff even when told I cannot because of mig. cant wait to see this thing finished.

Nic

Dude The time and effort you put into this thing is AMAZING. I’ve been following it since almost the start, even got my father in law to watch it along.

cannot wait to see this thing in action.

Josh

You just keep taking it to the next level Nigel. I thought this was impressive before you bult your own rear end!!

Your dedication and attention to detail is inspiring. Keep up the amazing (at home in the garage built) work!

Anthony

Just amazing! So talented to be able to make 90% of this from home! Oh btw do you have a twitter that I can follow?

Dwayne

if you looked around the site you’d find it

http://twitter.com/#!/@ETS_Australia

your welcome

Anthony

cheers, woulda looked but was on my phone, thanks dude

Tristan Deall

Yewww its looking great, keep it up!!

Alex Butti

Good work Nigel, actually excellent work! But the more I look at it, the more I think, “this thing is gonna weigh a ton” with all the chromoly tubing you’re using, it doesn’t seem it’s gonna be light. I hope I am wrong.

Keep up the great work!

david

Alex i think its a case of all the weight will be in the chassie plus strenth and distribution on the weight will be the big thing that just being light.

That tubbing isnt overly heavy then consider the weight of a car plus a cage in iy

Dustin gi

Incredible build. No more worse can convey how impressive it is.

Very nice work

Scott Doyle

Looking good.., I hope you will be making a few spares

Chris G

Awesome Ute, any reason why you don’t use metric threads? or is it just easier to get rose joints, steel tube etc in imperial sizes?

Also, if your mate that did your quarter panels can mould some decent whole tubs for rzn149’s, you could sell heaps of them. I can’t find one anywhere. Keep up the good work with the rest of it.

Adrian

hi,

i weld for two engineering companies myself. i can MIG, TIG and ARC weld comfortably.

the companies i weld for both produce/supply to kenworth trucks so i can relat to the automotive welding industry well i believe.

from what i can tell and see from reading your descriptions and seeing the photos you have done such an amazing job of this vehicle!! keep at it, hopefully ill see photos or videos of it in action oneday.

i can really see the art and passion you have looking at the photos it looks great!

also i was wondering are you a fabricator by trade or..?

Nigel

Thanks mate, i am a fitter and turner by trade so its something i do fairly regularly 🙂