Another week down, a heap more hours spent on the build. I just want to say i really love my garage and attribute this build to the space it sits in. I get home from work in the daylight, get stuck into whatever it is i need to do, walk out into the dark, eat some dinner, do the dishes, then return to the shed and plan out what I’m doing the next day. Thats basically my day to day routine.

Last week i ditched the nissan cradle, why? well i felt i could do something a little nicer and was at that point where i was about to build tubular arms and was not 100% sure that this cradle was straight, its also something I’ve always wanted to do to one of my S13s.

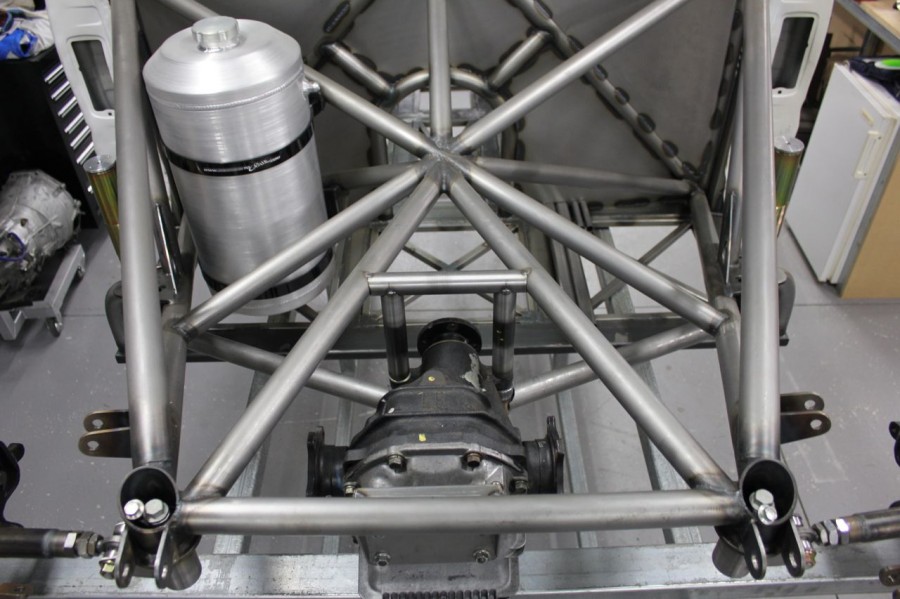

I started by hanging the diff in the centre of the chassis, that part was fairly simple, then machined up some bosses for the mounting points to weld tube too, then i made up a jig to hold the uprights (knuckles) in the position they needed to be, 955mm from the back of the cab to be exact.

So now i wait for more tube and design the mounting brackets for the new tubular arms I’m about to make, by the end of next week things should be looking rather good.

In other news i have ran my water and fuel lines through the cab and out both front and rear firewalls, i have to make up some bends with AN fittings welded on but i will have to wait for my motor to return before i do that. On the subject of the motor i took it up to Donny at to pull it down and make sure things are all good on the inside, when it returns it will be ready to setup in the S13 as a donor chassis for engine tuning at Dr Drift.

I think anyone who has built a race car before has got to that point of thinking about fittings and their head has just exploded (like mine), you have to write a list, order more than you need then face the fact that your going to have to re-order many more before the builds done. I decided to get mine from Summit in the US, always making sure the orders under the Tax threshold that we have in Aus.

For now the motor will be wet sumped and if i never have oiling issues it will stay this way, my filter is a Peterson dry sump style inline -10 filter.

Now because this motor will be shared with the two tone S13 i am running Jiffy-Tite quick connect no spill connectors, having this and the engine loom on a mill spec connector will make engine swaps a lot easier.

LP

The -20AN radiator lines (I’m assuming) are ex-NASCAR?

never seen those gold-lock earls hydro type fittings here before 😉

Ekka

The inline filter , how do they compare to your typical spin on filter in regards to service life , quality of filtration and pressure drop etc?

Alex Butti

There is another German company (named Staubli) that make quick-connectors. Keep up the great work Nigel.

Kamikaze BottleRockets

I smell custom uprights in the future. I know you’ve thought about it…

Nigel

Sure have, i was so close to doing it, needs to be rolling for WTAC though