After spending a couple of quiet days in NZ after the Hampton Downs final i started thinking, i thought about my Hilux and how i could build one that would fit within the regulations of the D1NZ rule book. I came up with a pretty simple plan that would make for another epic build, i have to shut out those thoughts and get my arse into gear and get this one done first. Heres what i achieved this week.

Before leaving for NZ i picked up a windscreen from the local glass place, they had one in stock and $125 later i had it sitting in the cab. I needed to get a windscreen so i could make the base for it to seal the cabin. After a lot of measuring and tacking i made up a neat panel that will do the job. Thanks to Celia my girlfriend for holding it in while i marked it up.

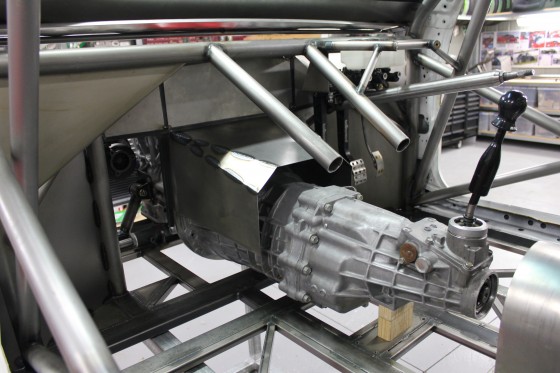

I ended up cutting the tube console out and starting to remake a sheet one. There was no way to sheet in the console around the tube and leave enough room for the driver, passenger, gearbox, exhaust, tailshaft, harness mounts and handbrake. Its a heap more work but will be worth it in the end.

The section of tunnel covering the bell housing (which is now done) will be welded in and then the rest will bolt in as one section and stretch all the way to the rear firewall.

The 3″ exhaust will run through the tunnel (tunnel will require a big bulge to house it) and then under the tailshaft where it will come through the rear firewall, branch off into two 3″ pipes and then exit flush with the rear diffuser in the centre of the “roll pan” area.

Ive been doing some work in the engine bay aswell, my intercooler arrived and i started to work on the front end to house it all, the entire front end removes via 4 bolts so i can basically walk into the engine bay if i need too, you may ask why the rad before the intercooler? Well that was going to be the only way i could package it all neatly without having to overcomplicate things. Ill have an air temp sensor but i think things should be fine in that department. The end tanks on the intercooler will be modified next week too.

I switched my welder over to AC for the first time ever, i tried some alloy stuff at work and was never really impressed with the result, for some reason this TIG seems to be the bomb when it comes to AC Alloy welding, i removed the comp cover off the turbo and welded a 90 degree elbow to it.

While i was on AC i decided to have a go at my new plenum design, what i had planned to do was buy a plenum shell off Hypertune (same as my 180) but it wouldn’t fit with the motor further back and the bar work i had, so i came up with the idea of a duel plane plenum, i had seen these used in many forms of motorsport, the idea is to evenly distribute the air to each cylinder without having a complicated big volume plenum. It runs a 14mm air gap that spans the length of the inlet tracts. I have no idea how it will go so i guess we will see, i have to now shape some nice end caps, any one have any alloy domed halves in 100mm x3mm wall?

There is still so much work to be done but its taking shape. Thanks for reading..

Tim

Looking amazing mate, this build and some other bits and pieces here and there and the main things that have made me want to get into fabrication as a proffesion 🙂 Any tips on where to start?

Flippy

try it in Garage 😛

Ryan

for dome and curved aluminium stuff give JNT performance a call (02) 42571000. they be able to get you what ya want

Nick

If intake air temps get high with the cooler there u could run a water or water/meth injection setup maybe???

cp aubin

be carefull whit the intake ….i would concil you to fin a triangle shape on it ..i did a custom intake for my civic(i know it is absolutly different) but when i run it the last cylindre take less air and then run richer of gaz that make the motor harder to set…dont if i would be the same thang for you but it is just a thing i sugerre you to chekc !

AND continue ….if i had a 1 million to give illl give to you to finish this build ! 😛

A canadian friend that fill your blog like the bible !! 😛 haha

John Jones

Man looking good guys. Can’t wait for it to be finished and on the hard surface beneath our tires and leaving rubber compound on the surface made of different minerals and elements. Time to pop smoke and show everyone who means BUSINESS

Aaron

Looking great, it’s good to see some more progress on this thing. Loving the whole build!

Btw, more driveshaft tube for the plenum?

tom

so awesome, every update gets more interesting and ingenuous!

One Fifty

I’m still lovin’ the updates mate!

Mark Watson

Also running the intercooler closer to the engine means shorter pipes, more response. Will be interesting to see how the setup goes. Nice work nigel always trying something different.

Justin Rood

Just send the 180 to NZ 😉 It’ll hold it’s own no worries! Is the front suspension in this set up the same as Nissan? Or have you moved radius rod and lower arm pickup / x-member higher to compensate for the ‘moar low’?

Looking awesome in any case, will be great to see it out on track 😉

Nigel

Its pretty much the same as an S15 but 150mm longer, everything is way up high in this and the body is way down low. Kinda hard to explain but yes the front is all as per S15 specs, the 180 might make its way over after WTA but we will see! Good to see you at D1NZ bru.

Rob

This thing is insane. Your work is insane. How the hell do you keep your shop so clean…everything’s so clean. Do you have a dirty work bay? Just amazing.

Nigel

I built a room that i do all my cutting in, if i didn’t things would be a real mess, i do sweep the shed out nearly every week too haha

benny

So epic dude! Amazing, wish i had as half as much skill as you do

Alex Butti

Nigel, if I may suggest, go with a thicker plenum. 3 millimeter looks flimsy.

The reason why I bring this up is because of vacuum with the turbo spool, it might crumple.

There’s a company called RMR (Ross Machining Racing). They sell a bunch of parts for DIY intake manifold:

http://www.rossmachineracing.com/index.htm

Best of luck!

Peter

Keep the updates rolling in Nigel!!

This may be a stupid question, but I’m assuming your not going to be running windscreen wipers?

Just gonna rainX it up if it rains?

Nigel

Thanks mate, yep no window wipers, i dont run any on the other cars either 🙂

Bailie

nice work. gonna be very cool. but i dont agree with drawing hot air through the intercooler… kinda defeats the purpose of having one in the first place. maybe a v mount setup would work better?

Nigel

Its all changed now, no hot air intercooling.

bailie

Yeah just saw the latest pics. Looking very cool.