Its been a busy week working on the hilux, a lot of stuff has happened, ill run you through the details in this post.

Ive done a heap of sheet metal work, i have filled in all the gaps between the bar work and the removable cab to make everything seal nicely and limit the amount of smoke that enters the cabin. The firewall is now complete and the window is sitting in just right.

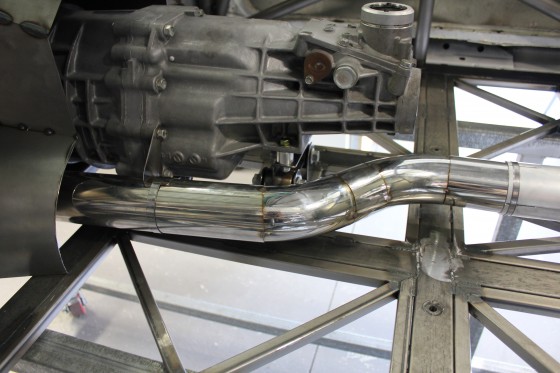

The mystery of the exhaust is now solved, i really did want the tailpipe running out the middle of the rear diffuser so i came up with a nice stainless dump pipe off the turbo, then stainless all the way to the end of the gearbox.

Ive been making my exhaust mounts like so, the exhaust will be hung with hose clamps, its neat, functional and easy to replace if needed.

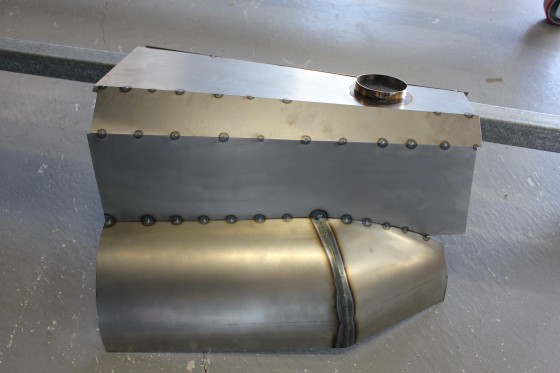

It all gets covered by this removable tunnel i have 1/2 finished.

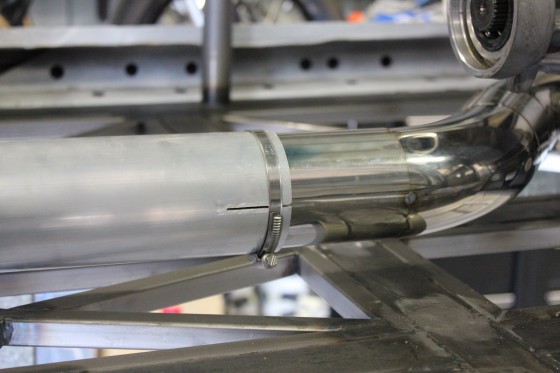

Where the stainless pipe ends at the back of the gearbox there is still 2.5m to the end of the tub, thats a fair amount of weight for a straight pipe, so i decided to use alloy for the exhaust, using 80mm by 2mm wall it slips over the 75mm 3″ stainless I’ve been using.

Some grooves and a hose clamp do the job at securing the alloy to the stainless.

Under the diff is another exhaust bracket.

From this point on the exhaust will split into twin 80mm and then exit in the centre of the rear diffuser. Ill have to wait till the rear quarters are done till i make that though.

I have also been working on the intercooler and intake, its all taking shape and I’m waiting on my AC welding skills to be up to scratch before i weld all this together.

Until next time!

Isaac

So cool to see it all coming together mate, workmanship is excellent as per usual good work

Paulie

i like the design of intake manifold you’re doing. should provide equal flow and pressure to each runner just nicely.

obviously the rest is top notch too.

steven.

wooo…! Liking the exhaust mounts.

Franklin

Looks awesome!

Dave

What about if instead of hose clamps you use slip joints with springs to hold them together like a lot of rally/race cars do. Will make removing them a breeze even when hot. Here is what I’m talking about.

http://www.danstuff.info/furyracerb154.jpg

Landberk

I’m liking them mounts too! Gonna copy you there Nigel 🙂

How do you think the alloy pipe will hold up? Thinking about doing that also.

Lloyd

Your work is just amazing.

Also do you still sell the drift knuckles?

Peter

Great idea for the mounts.

Have you thought about doing a feature on your first 180sx, as well as a bit of a write up on how he came about? I know I would be interested to see it.

Scotty

Farout its actually that good!

so inspiring your fabrication skills are bullshit good!

cant wait to see it all tie together

Joey

What tools do you use to cut all the shapes out of sheet?

Alex Butti

I’m not sure Aluminum is the right choice for an exhaust. It’s very light compare to SS, but much softer and weaker at high temperature.

On top of that Aluminum does not help scavenging. SS retains better the heat, making more HP.

Good luck with the project.

Steve Kae

o_O madness

Nathan

This is the most beautiful thing I’ve seen in my life.. every step is sheer brilliance!

this build is an inspiration.. figuratively and literally.

Inte

When your finished with the aluminium exhaust, does it get coated? Aluminium begins to melt at 660celcius

louis

don’t you think that the hose clamps will vibrate off, don’t think they are really a suitable mount.

and the alloy pipe seems like it’ll be warping on the first lap around the track.

Besides that the builds awesome, well done.

Joshua Anderson

……..THIS IS A MASTERPIECE IN IT’S OWN RIGHT AND ITS NOT EVEN FINISHED WELL DONE M8 YOUR LONG HOURS ARE FINALLY PAYING OFF……………………

bry

Exhaust mount and alloy tubing inspired from a certain miatabusa :P?

http://photos.motoiq.com/MotoIQ/Project-Cars/Miatabusa/i-4mmn7bk/0/M/P1040939-M.jpg

Nigel

Ahh i knew i got the idea from some build, come to think of it thats the one! Been following that for a while, going to be such a cool roadster

Michael

Nice build mate but I think you might need more heavy duty hose clamps from all the vibration and jolting from the track.

Maybe the hose clamps that are used with intercooler piping which have a 8mm nut to tighten it.