Still on a high from actually getting this car running I had a call from Aaron saying that the dyno was free from thursday morning to (if we needed it) the weekend. I have a love hate relationship with dyno’s, it’s the most stressful environment for any builder but also a true testing ground for the builders skill.

But first things first I had to get prepared.

My new contactless Throttle Position Sensor arrived and I quickly made it work, I cant stress enough how much this little sensor means to the opperation of this engine, with no Manifold Air pressure to measure this tells the ECU about 75% of the information it needs to perform properly.

With that back on and working I went over the car and did my final checks, I raised the suspension for the dyno, corrected the rear allignment, changed the rear wheels for skinnier (cheaper) rubber. There was no need to wear out expensive semi slicks on the dyno as they get hot, wear out and actually create more drag and therefore less HP, with every single HP accounted for on this car its going to matter!

My poor trailer sits outside its whole life, I picked it up after sitting for 6 months and gave it a good clean up.

I drove the car down the driveway and prepped it for the trailer.

In the dark I strapped the car in and then mentally prepared for the next day.

Some fresh BP Ultimate 98 the next morning.

A quick check to see if the straps are still tight.

Then off to the dyno, I love my VW van by the way, its the greatest car I have ever owned, it does everything perfectly!

Pulling up at DTM Automotive I roll the car out and start to get really nervous.

Aaron and the team here at DTM Automotive run the most professional business around, it shows, they even vacuum the floors in the dyno bay before and after each tune up.

I just hoped like hell that I had given Aaron the best case scenario by building the car right and having a trouble free car to tune.

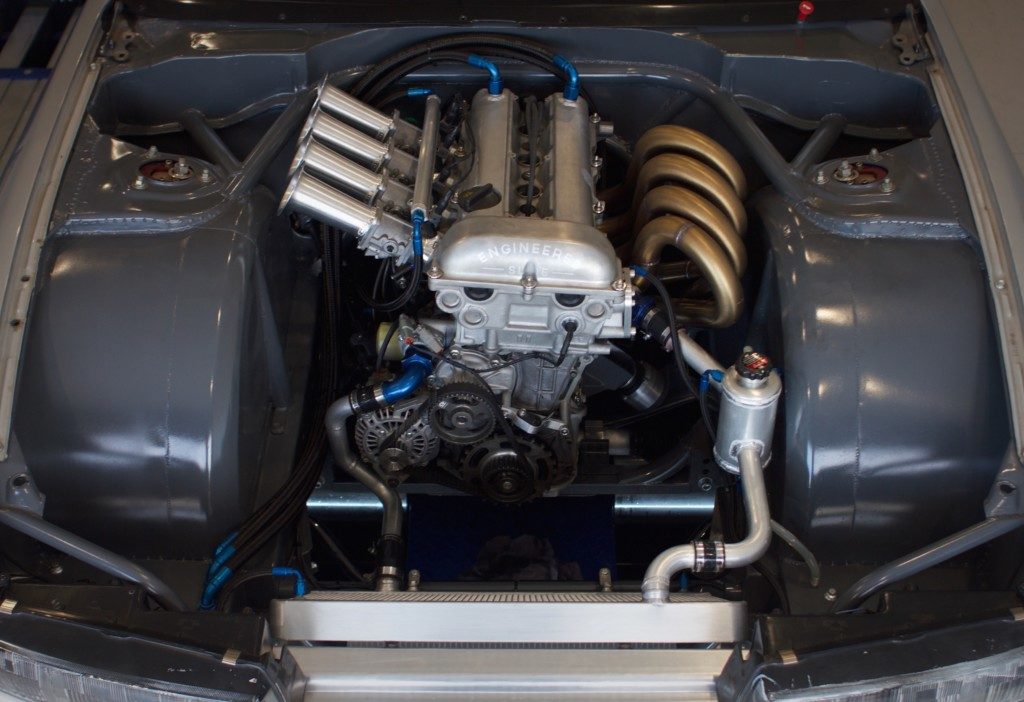

If you have been in this situation before then you will understand, if not let me explain what its like; as Aaron is getting the car up to temp I am looking over everything, the coolant system that I had built, does it leak, does it cool adequately, does it bleed air like I designed? The pulley system…. do those ex Nascar dry sump pulleys work how I designed? Do the adpaters work properly? Will the belt fly off at high RPM? Does the timing system work properly? Hows the wiring going? I hope those resistors I put in place of the charging lamp are staying cool, the alternators charging, thats good! Then there’s the exhaust system, it looks great, no leaks, sounds amazing, the inlet system, seems great, the engine…. everything sounds good, the sump isnt leaking, its holding really good oil pressure, the 6 speed gearbox is smooth and quiet, the clutch works great, the brakes work great, theirs no excessive vibrations from the tail shaft or the diff I built with the 4.9 gears. All seems good.

There’s just so much to look at but after a while its performance soothed my nerves and I started enjoying listening to it scream.

Its has a level of simplicity I haven’t encountered before, I really like it.

Simply touching the throttle instantly brings it to life, I didn’t really think about the response thing too much, but I really feel it now.

We ended day 1 with a few hours done on the tune, Aarons pretty happy with the results so far and we are heading north of 4,000rpm tomorrow. Stay tuned!

Update! I just got back from the dyne where Aaron has just wrapped up the tune, everything went perfectly well and it churned out a lazy 120 rwkw which from a Mainline dyno is completely respectable for a stock compression NA 2.0.

Im more than happy and now can’t wait to drive it.

How good do those headers look now!

Seeing it all spin past 8,000rpm with no dramas gives me so much confidence in it.

Not to mention spending the weekend relaxing instead of rebuilding the engine.

In the same way I enjoy motorcycling for its rawness this brings a little of that to my 4 wheel life.

Again thanks to Aaron and the team at DTM for their involvement in the tuning process.