The most used tool in the building of this car is not the welder or the angle grinder its the tape measure, vernier calipers, ruler and micrometer. It wasnt until I embarked on the gearbox conversion that I found the true value of decent dimensional drawings.

At the very start of this build 3 years ago I didnt care about dimensions, I just wanted everything to fit within the space I had, I didnt draw anything or really plan on paper what everything was going to look and fit like, I just did it as I went along. I can pretty much attribute all the little stuff ups along the way to my lack of dimensional planning.

Would I change what I have done? No, why? Well I didn’t understand what I needed to do, its like going for a job at a place that requires experience, you cant get experience if they wont give you the job right? So I threw myself in the deep end and made what I wanted to make without any on paper plans. All the lessons and experience are now part of me and I am much smarter for doing what I have done.

But if I was to do it all again I would spend three months sitting behind a computer screen mapping out my chassis and I believe that 3 months would save me over a year on the shop floor. I couldnt do this before because I didnt understand what was required, I had a fair idea but this gearbox conversion has enlightened me to the power of numbers and planning.

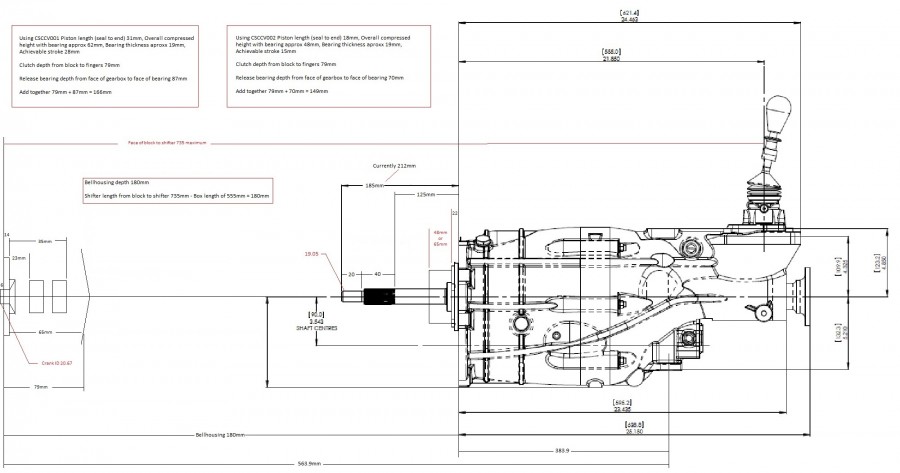

You see I knew just about the entire physical size, mounting points, input shaft size and shifter position even before lying eyes on the gearbox. The drawings that Quaife supply on their website tell you just about everything you would want to know. Couple this with a dimensional drawing of an SR20 and you could build the entire thing on the computer before even picking up a tool.

So with all these fun facts in mind would I build what I have again? Sure would, I could save a heap of weight, make everything integrate into the chassis a lot nicer, make all the sheet metal work removable and alloy, the suspension layout could be a lot more “motorsport specific” utilizing CNC technology for a heap of the hard to make parts, utilize laser cutting technology to make all the tabs and then plan out all the tube work and even 3d laser cut those so everything fits together like a jig saw puzzle. Come to think about it I could even work with an Engineer so I could take steps to register my creation on the road.

It gets me thinking about using all my running gear and electronics and just building another chassis rectifying all those little things I would rather do differently on the next one.

All this sounds awesome but its also expensive, as soon as you send something out to save yourself time then your paying money for something you could do yourself. So whats my dream? Well a shop full of machinery would be a good start, a neat 5th axis CNC mill and laser cutter would be a good start. Hrmmm that Quaife gearbox dosnt seem so expensive anymore does it?

Fast Torque Peformance eng

mate, I built my first race car (Top Doorslammer Dragcar) designed on Solid Works and the benefit was unmeasurable. I am afraid to think what i would have ended up with had i built from mind source only. check it out on my fb pg team peter blake top doorslammer.

Nigel Petrie

Looks amazing, the benefits would have been huge im sure, theres possibly a lot more to take into account with your setup compared to mine, a drag car would need a lot of chassis flex tuning and thats where your solidworks models would come into play i bet!

rXc3NtR1c

I do my stuff with Bend-Tech and Sketchup, I can’t justify thousands on software for what amounts to a hobby. Imagining things in 3d is cheap compared to working out ideas in metal, although sometimes a little bit of both is good as well. Remember, it’s not the destination – it’s the journey 😉

Nigel Petrie

To true, ill have to look into that software, thanks

4agpowered

love sketchup

piece of piss to pick up aswell!

ryanc

Let me go get my popcorn. The next 10 years on this blog are going to be outstanding.

Nigel

You may need a lot of popcorn, geez 10 years, I’m getting married soon so it may all be over haha

evocom

I’ve been loving your work, sure has come along way since the single carport days. You may be interested in this build, it’s a yamaha R 1 turbo, rwd, front engined mini that’s had a lot of solid works design. It’s a very interesting read. Keep up the outstanding work.

Nigel

Thanks mate, ill check that out now, that single garage still haunts me.

evocom

Oops forgot the link.

http://www.theminiforum.co.uk/forums/topic/98744-little-less-conversation-a-little-more/

SteveT

Love what you do but I have to say that trying to build a road worthy version will be impossible to register, being that it will have to be an icv and no modified or Turbo engine can meet the emissions standards for 2013 requirements. I was trying the same with my s15 and no standard strucual members can be removed or altered. Pure race car is the way to go.