Another week down and a heap more progress, whats happened this week, well heres a look.

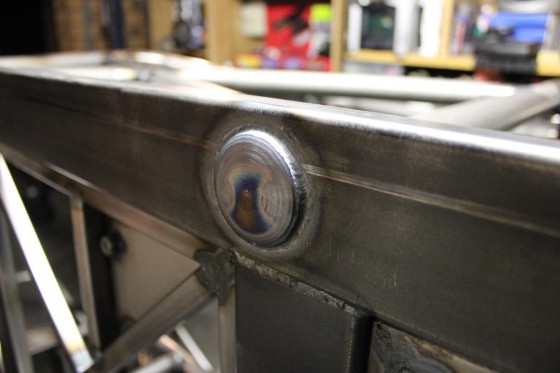

This week i focussed on all the bits that take a lot of time and fiddling around. I stripped it back to a chassis and finished all the welds i couldnt get to, its quiet easy to roll over in the shed. The seat bosses were welded in and give strength to the floor sections as they act as crush tubes welded from both sides.

These bosses run up into the chassis and act as “bump stops” if things get a little close to the tarmac, if i didnt intergrate these then the floor would be rising and the tube work would be punching through the floor. I know its going to get dinged up underneath but im doing as much as i can to minimise it.

The steering rack mounts were tacked in to get it rolling and make sure its where it needs to be, with big lock you need the steering rack as far forward as possible, the less “overcentering” of the tie rods the better the feel at big angle. Happy with where it was i welded them up. Still havnt done any engine mounts but when i do it will strengthen the entire engine compartment.

Seat mounts done, scrape pads done, final welding done and a good wipe over with CRC. Tomorrow i will reassemble everything and get it ready to trailer (i still need one!) to WTAC.

Luigi

What material is the tubing? CrMo or regular seamles steel? Do you use TIG in all the welding? Thanks 🙂

CS

I believe just normal steel. Dig up the “ETS Drift Ute” entries, you’ll find the answer.

Bids

Looks like your mastering that TIG nige 🙂

Jess

awesome dude cant wait to see it next week. I’m flying out tomorrow morning 🙂 am so pumped to see your 2 cars!

teknik22

whats that little toy u got there in the last pic

Dan

I think its a WR250X judging by the other snippets of intespersed in the blog.

GrandMighty

Is that Supermoto in the last picture a Husaberg? The swing arm looks familiar…

JakeFromCali

I never really got the hang of TIG welding, but some of your welds look like a machine did them. I’m feeling inspired to bust out the ol welder 🙂

Nigel

Thats the spirit, im still learning, i think TIG is a comfort, control and confidence thing. When you have those three factors down then you can weld like a machine.